Our Blog

Get the latest insights and knowledge leadership from our inspection and precision automation experts.

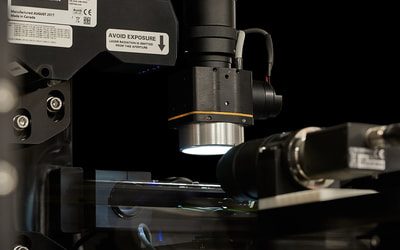

Improving Long-Term Performance of Metrology Systems

Three key factors that influence the long-term performance of automated metrology systems installed in uncontrolled environments.

3 Key Benefits of an Automated Non-Contact Metrology System

Microns and milliseconds matter when inspecting medical staples, fitness trackers, and smartphones to meet government regulations or consumer standards.

Deciding Between a Non-Contact Metrology Platform and a Traditional CMM

Understanding the features of a non-contact metrology platform versus a traditional contact CMM helps manufacturers choose the right inspection equipment.

Speed Wins in Contact vs. Non-Contact Surface Profiling

In surface morphology, non-contact optical methodologies provide the same measurement results as a conventional contact profiler in a fraction of the time.

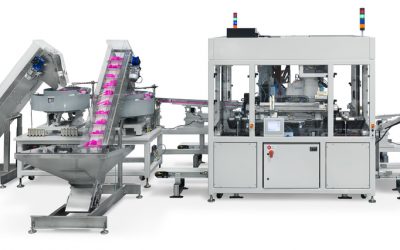

Scaling Up to a Smart Factory with Automated Assembly

Automated assembly stations provide higher productivity and product quality while lowering product costs and the space required for conventional tooling.

Benefits of Consolidating Metrology Operations into One System

Automated metrology platforms ensure high quality finished goods and lower total cost per part by consolidating multiple operations into one system.

Why Material Handling Stage Design Matters

When high volume manufacturers need 100% inspection of parts, non-contact metrology stage design should not only maximize sensor use, but also easily measure different parts on the same system. Whether it’s ensuring smartphones perform to meet customer satisfaction or...

IMTS 2018: Focus on Automation and Digital Technology

Automation, data and the need for speed were the driving forces behind the manufacturing quality assurance trends featured at IMTS 2018 in Chicago this past September.The International Manufacturing Technology Show (IMTS) 2018 featured the latest manufacturing...

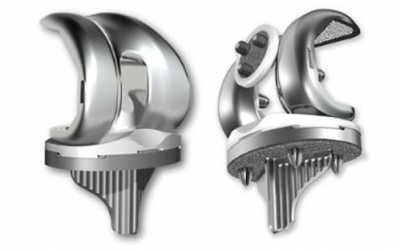

Measuring Complex Part Geometries

Tightening dimensions are a trend both for components and for an increasing number of parts and devices. Incorrect part dimensional measurements can lead to failure and costly recalls.Small consumer products pack an enormous amount of technology into tiny units. In...