Downloads

Access application notes, case studies, solution sheets, and white papers, or download product briefs and brochures.

Whitepapers

Using Automated Vision Inspection in Medical Device Manufacturing

Has part variability and the use of manual inspection proceses created issues with achieving your product quality and yield goals?

Importance of Process Automation in Medical Device Manufacturing

Finding the right automation partner with the core competencies to automate your manual processes is necessary and critical to maximize production yields.

From Proof-of-Principle to Commercial Solution

When automating manufacturing processes of complex medical devices, proof-of-principle activities are imperative to meeting quality and performance objectives.

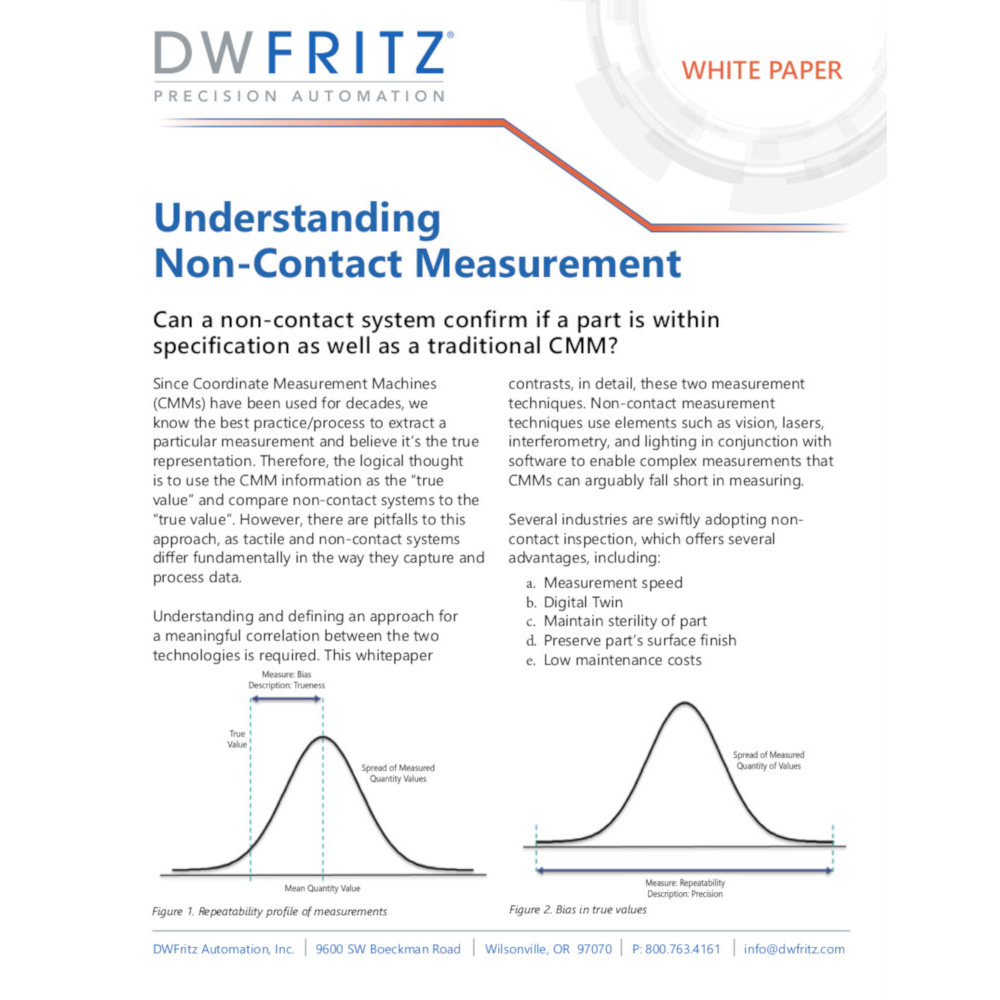

Understanding Non-Contact Measurement

Coordinate Measurement Machines (CMMs)have long been considered the standard for determining a true measurement, but can a non-contact system if a part is within specification as well as a traditional CMM?

Case Studies

Class 3 Medical Device Package and Label Inspection

Ensuring pharmaceutical and medical inspection compliance with machine vision increases reliability, decreases costs, and dramatically reduces contamination risks.

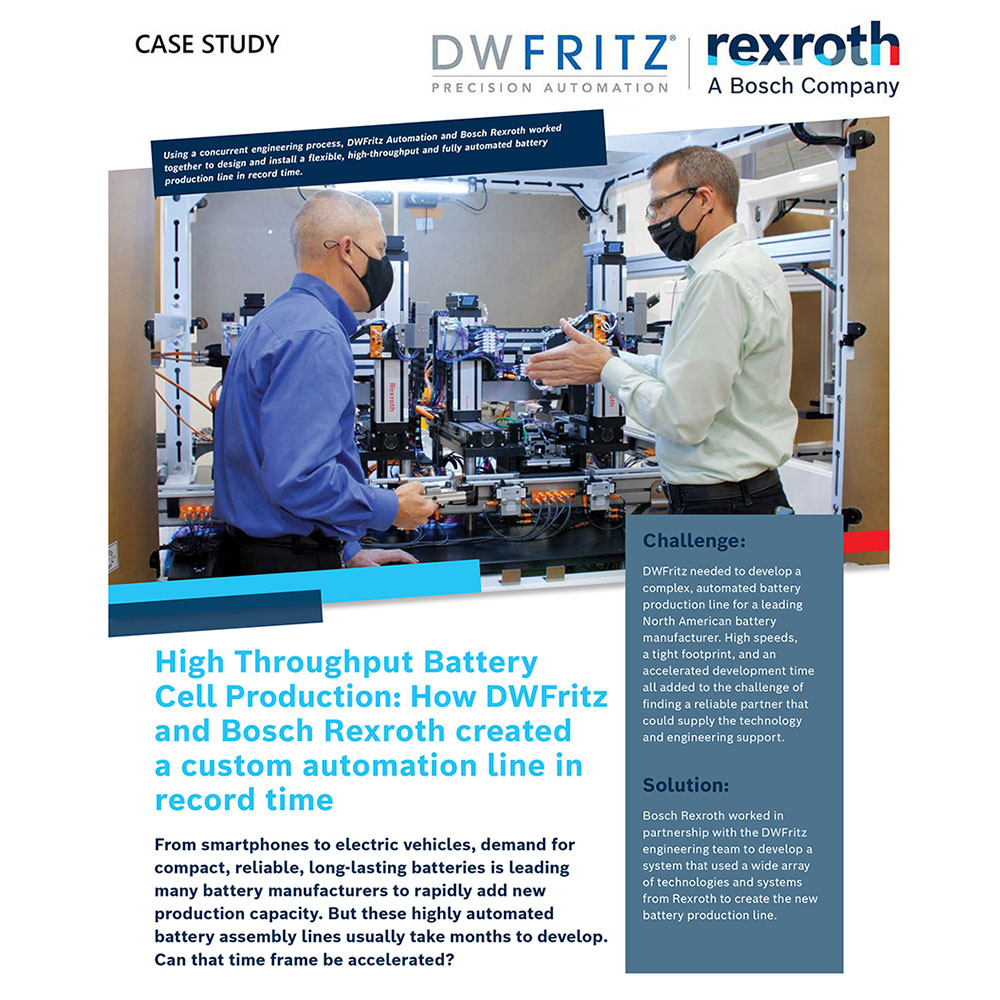

High Throughput Battery Cell Production

From smartphones to electric vehicles, demand for batteries is leading battery manufacturers to rapidly add new production capacity. Can developing highly automated battery assembly lines be accelerated?

Inspection & Metrology Solution Sheets

Automated Flex Circuit Bonding & Inspection

A consumer products manufacturer needed an automated system to bond and inspect flex circuits in under two minutes per press.

Wafer Metrology Tool

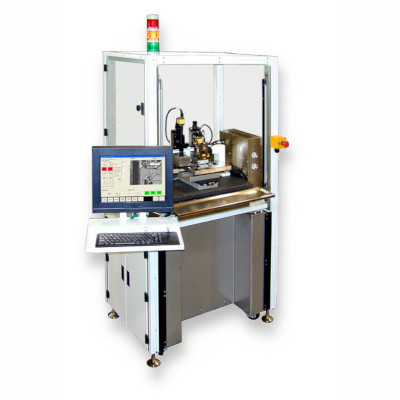

A semiconductor manufacturer needed an automated metrology tool to detect and measure laser-cut trenches on silicon wafers with accuracies down to 1 micron.

High Speed Sorting System

A sorting facility needed a high-speed, automated system to identify and sort a singulated stream recyclable components.

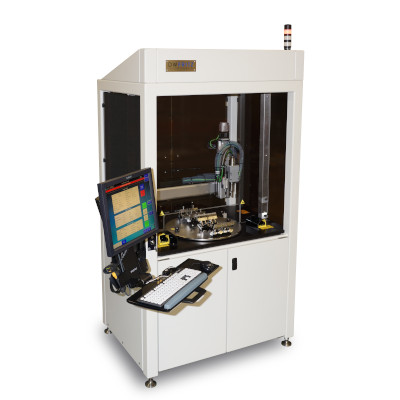

Automated Implant Inspection System

A medical device manufacturer needed to measure multiple different types of medical implants and small parts, including screws, hooks and connectors.

Ultra-Precise Substrate Labeler

A medical device manufacturer needed an ultra-precise system to print and accurately apply high-resolution bar-coded labels to both sides of a glass substrate.

Precision Vision Inspection System

A consumer product manufacturer needed a high-accuracy, automated vision system to perform 100% inspection of structural adhesive pattern and die placement on a production line.

Automated Valve Evaluation System

A medical device manufacturer needed an automated system to replace an existing manual pulsatile flow tester for heart valves.

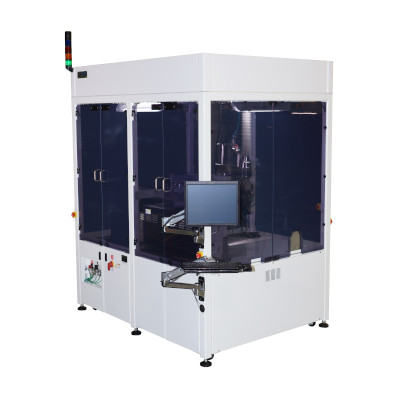

Automated Seal Inspection System

A medical device manufacturer needed an automated, advanced vision system to provide 100% inspection of the tyvek seals on medical packages, including shape, transparency, and color.

Sensor Soldering System

A medical device manufacturer needed a system to automatically install and solder pre-cut, formed sensors to anode and cathode solder tabs.

Percutaneous Aortic Valve Test System

A medical device manufacturer needed a self-contained test chamber capable of verifying the performance capabilities of four sizes of aortic heart valves.

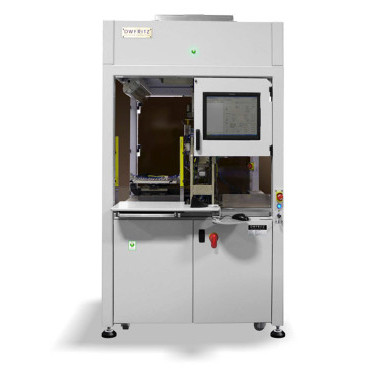

Surgical Auto-Loading and Inspection System

A medical device manufacturer needed an automated system designed to place surgical staple cartridges into packaging and deliver the loaded packages into an in-line sealing system.

RSA Test System

A medical device manufacturer needed an automated proof-of-concept system to test reusable sensor assemblies (RSA) and transmitted signals from a unique miniature biosensor.

Polishing Pad Inspection System

A semiconductor manufacturer needed an automated system to clean and inspect polishing pads for semiconductor wafers.

Roll Bar Hole Inspection

A consumer electronics manufacturer needed an automated system to inspect and measure critical dimensions in a strip of individual bars.

Color/Gloss Inspection and Sorting System

A consumer electronics manufacturer needed a system to inspect components for color and gloss characteristics.

Ocular Implant – Proximal and Distal Body Inline Inspection System

A medical device manufacturer needed a stand-alone system that provides an automated inspection of Proximal and Distal bodies immediately after they are molded.

Precision Assembly Solutions Sheets

Precision Adhesive Dispensing System

A semiconductor manufacturer needed a fully automated system to dispense precise quantities of adhesive to predefined areas on a customer-supplied wafer.

Precision Pillar Placement Tool

A leading glass manufacturer needed a system to automatically assemble high-quality vacuum-insulated glass products.

Implant Coating System

A medical device manufacturer needed to automate the batch processing of dental implants through an electrolytic plating process.

5-Blade Lubraplate Assembly System

A consumer product manufacturer needed to automate the process of welding, lubriplates onto razor cartridges, inspecting, laser marking, and packaging them for shipment.

Laser-Engraving and Assembly System

A medical device manufacturer needed an automated system to laser-engrave and assemble titanium vial and cap components at a rate of 7.5 seconds per assembly.

Automated Wafer Laminating System

A semiconductor manufacturer needed an automated system that combines heat and pressure to process six-inch wafers under a proprietary process.

High-Speed Syringe Assembly

A pharmaceutical manufacturer needed an automated, high-speed tool to orient, lubricate, assemble, and output medical syringes to a packaging line.

Robotic Wire Weaving Tool

An industrial manufacturing client needed an automated system to wrap wires around cast iron metal disks to reduce labor costs while maintaining high quality and throughput.

High-Speed Connector Assembly

A consumer electronics manufacturer needed an automated system designed to assemble, swage, and inspect small components into electrical connectors.

Laser Assembly System

A consumer electronics manufacturer needed an automated system to assemble and laser-weld molded plastic atomizer components into finished atomizer assemblies.

Coating Application Tool

A medical device manufacturer needed an automated system designed to etch and coat medical components.

Microfluidic Assembly System

A medical device manufacturer needed an automated system designed to assemble and laminate two microfluidic subassemblies used to create a six-layer diagnostic mediu.

Ultra-Precision Excise & Attach System

A semiconductor manufacturer needed an automated system that would excise individual nozzle plates from a reel of input material and accurately attach the nozzles to a silicon wafer.

Heart Valve Ultrasonic Welding System

A medical device manufacturer needed a system to fixture, precisely map the lapped seam profile, and uniformly weld several aortic and mitral heart valves component sheets.

Panel De-bonder System

A semiconductor manufacturer needed a system pilot system to de-bond a thermal film and wafer carrier from a prior process.

Sensor Probe Encapsulation System

A custom automated system for a medical device manufacturer that integrates multiple subsystems to automate the encapsulation of lead frame assemblies.

LCM Alignment and Press System

A semiconductor manufacturer needed a system to assist final cable connections and routing between a liquid crystal module (LCM) subassembly and display housing.

Battery Cell Test/Sort System

An electric vehicle company needed a pilot production tool to pick and place lithium-ion cells for testing, and sorting good cells from bad cells.

Tack Pin Insertion System

A consumer electronics manufacturer needed an automated proof-of-concept system to test two different fastening methods as well as different product attributes.

Embolic Coil Processing System

A medical device manufacturer needed a semi-automated system to trim platinum wires from incoming coils before applying and curing a UV adhesive between the coil and proximal bead.

Ocular Implant – Assembly and Testing System

A medical device manufacturer needed a stand-alone station that provides automated assembly and testing of a Distal Sub-Assembly before completing final assembly with the Proximal Sub Assembly.

Modular Battery Cell Processing and Assembly System

A battery manufacturer needed an automated battery cell processing and assembly system that is scalable to various cell form factors and throughputs.

Part Assembly and Disassembly System

An industrial electronics manufacturer needed an automated system to rapidly manipulate, assemble, and sort parts into sub-assemblies.

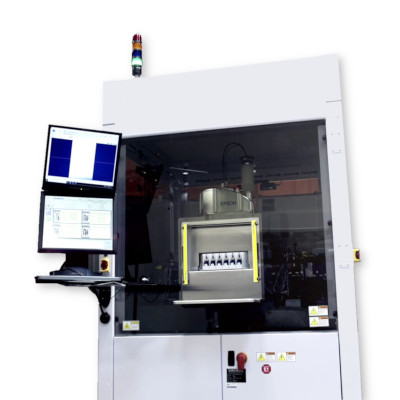

Camera Focus and Alignment System

An industrial electronics manufacturer needed an automated system to precisely focus up to 16 different types of cameras.

Product Brochures

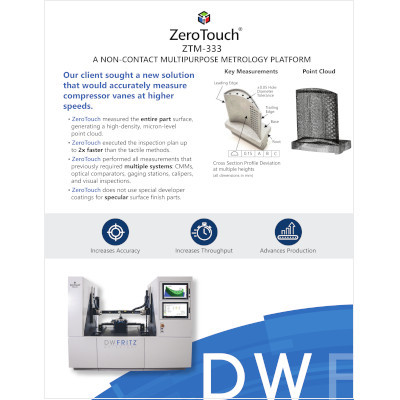

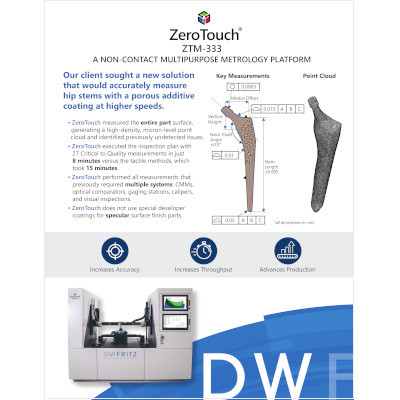

ZeroTouch® Flexible Metrology System

A high-speed, non-contact multipurpose metrology platform that inspects parts faster than traditional CMMs.

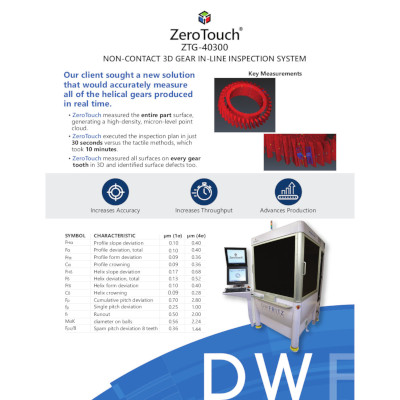

ZeroTouch® Gear Metrology System

A non-contact, 3D inspection system to perform near- or in-line 100% tooth inspection and metrology of gears.

ZeroTouch® Rotational Metrology System

A precise, high-speed metrology and inspection system that measures rotors, stators, brake discs, and other cylindrical parts.

Application Notes

ZeroTouch® Application Note: Compressor Vane

Our client sought a new solution that would accurately measure compressor vanes at higher speeds.

ZeroTouch® Application Note: Helical Gears

Our client sought a new solution that would accurately measure all of the helical gears produced in real time.

ZeroTouch® Application Note: Knee Joint Implants

Our client sought a new solution that would accurately measure knee joints at higher speeds.

ZeroTouch® Application Note: Stator Frame

Our client sought a new solution that would accurately measure all the stator frames produced.

ZeroTouch® Application Note: Brake Rotors

Our client sought a new solution that would accurately measure geometry and detect defects for all of the brake rotors produced in real time.

ZeroTouch® Application Note: Hip Implant

Our client sought a new solution that would accurately measure hip stems with a porous additive coating at higher speeds.

ZeroTouch® Application Note: Stator Assembly

Our client sought a new solution that would accurately measure all 300 hairpin stators and also inspect weld bead dimensions for defects.