Energy Storage

Custom solutions designed with our expertise in the latest technologies to meet the demands of this growing industry.

We use the latest technologies to build state-of-the-art automation solutions to assemble and inspect battery packs and other energy storage systems, ensuring the reliability and high quality the industry has come to expect. Whether you need a storage solution for the electric vehicle market or the solar industry or to augment the power grid, we have the capability to design, manufacture, and install automation systems and production lines to help build your energy capacity.

Key Applications

- Battery assembly and test

- Solar panel assembly, inspection, and test

- Flow battery production

- Inverter assembly

Technologies

- Advanced material handling

- 2D and 3D multi-sensor vision system

- Plasma treatment

- Precision dispensing

- Robotics and machine vision

Ready To Get Started?

Advanced Solutions for Energy Storage

Energy storage technologies are now a fundamental aspect of the future. From electric vehicles to solar panels, we design and develop innovative, automated manufacturing and assembly systems offering a high degree of flexibility, precision, and reliability.

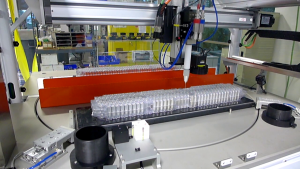

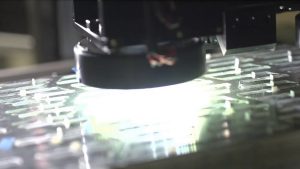

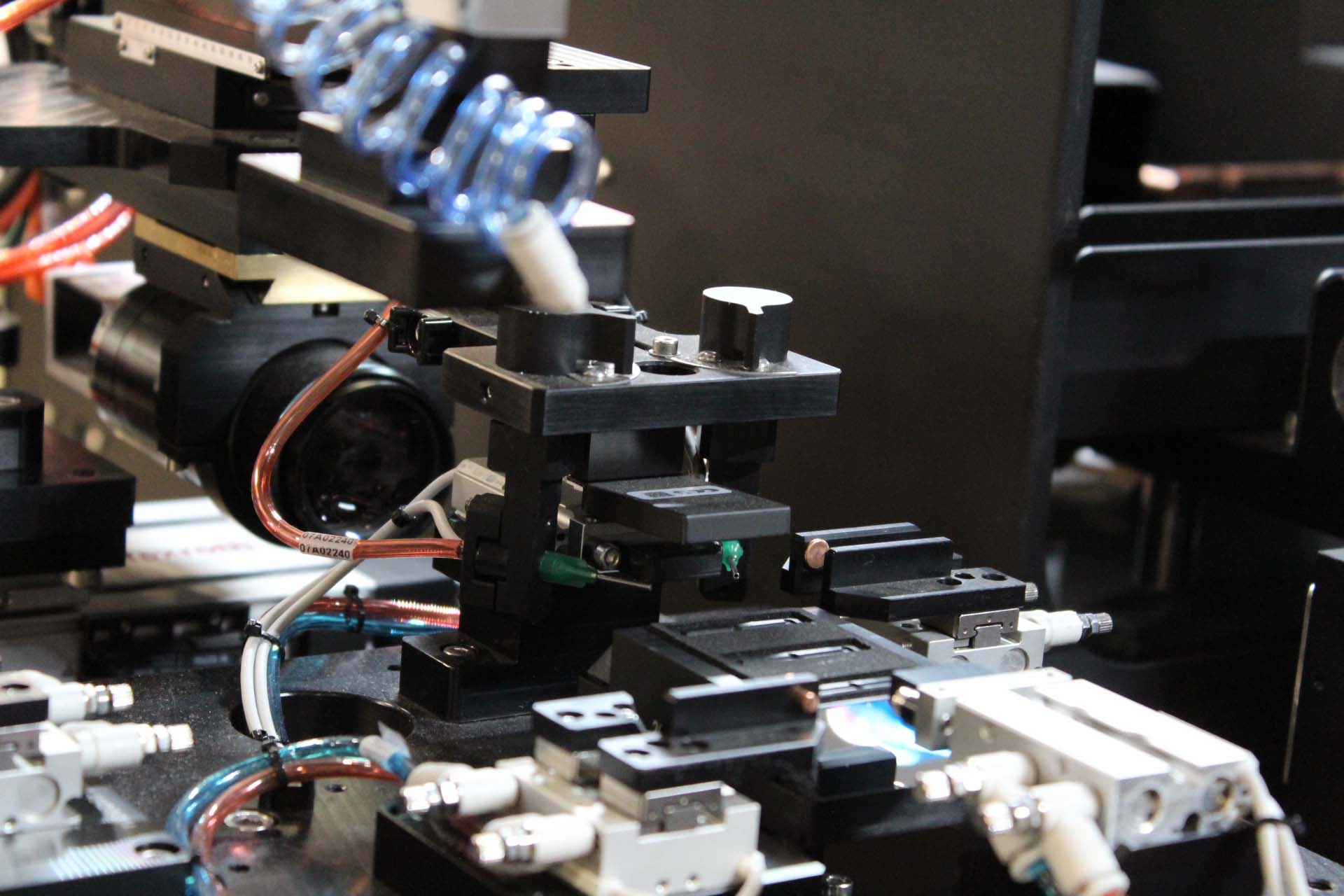

We have extensive experience working with clients and industry partners to develop fully automated high-speed battery manufacturing lines using precision material handling and motion control coupled with advanced web handling to ensure the precise stacking of the cell with micron-level accuracy. Our lines use custom software, conveyors, vision systems, defect detection technology, precision dispensers, laser trimming, and magnetically driven flexible transport systems to move and process the cells with speed and accuracy.

Electric vehicles are measured by their ability to achieve longer distance with high reliability, and energy storage plays a critical role in this equation. Producing high-quality batteries requires precision assembly and inspection processes to extend the cell age, prevent leaks, and confirm cell performance uniformity. DWFrtiz can engage at any level of the battery manufacturing process with the capability to develop a test line to determine the best solutions, and then design and develop those solutions into a multi-segment energy storage solution.

Success Stories

High Throughput Battery Cell Production

From smartphones to electric vehicles, demand for batteries is leading battery manufacturers to rapidly add new production capacity. Can developing highly automated battery assembly lines be accelerated?

Battery Cell Test/Sort System

An electric vehicle company needed a pilot production tool to pick and place lithium-ion cells for testing, and sorting good cells from bad cells.