by maneet@allfriends.studio | May 4, 2021 | Lang - EN, Metrology, ZeroTouch

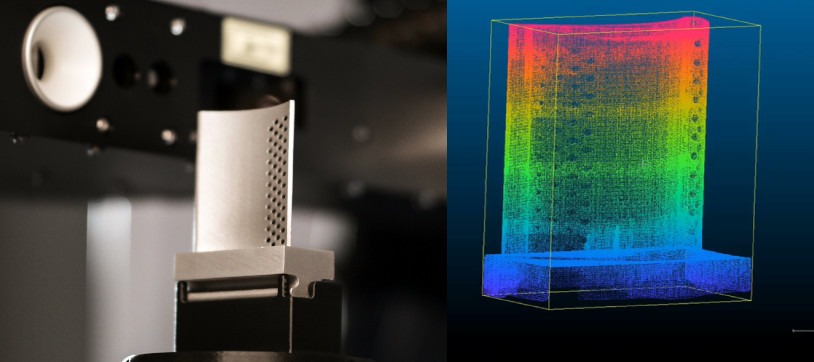

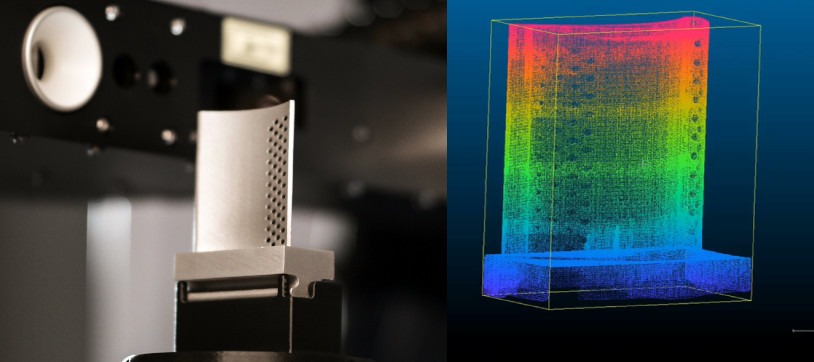

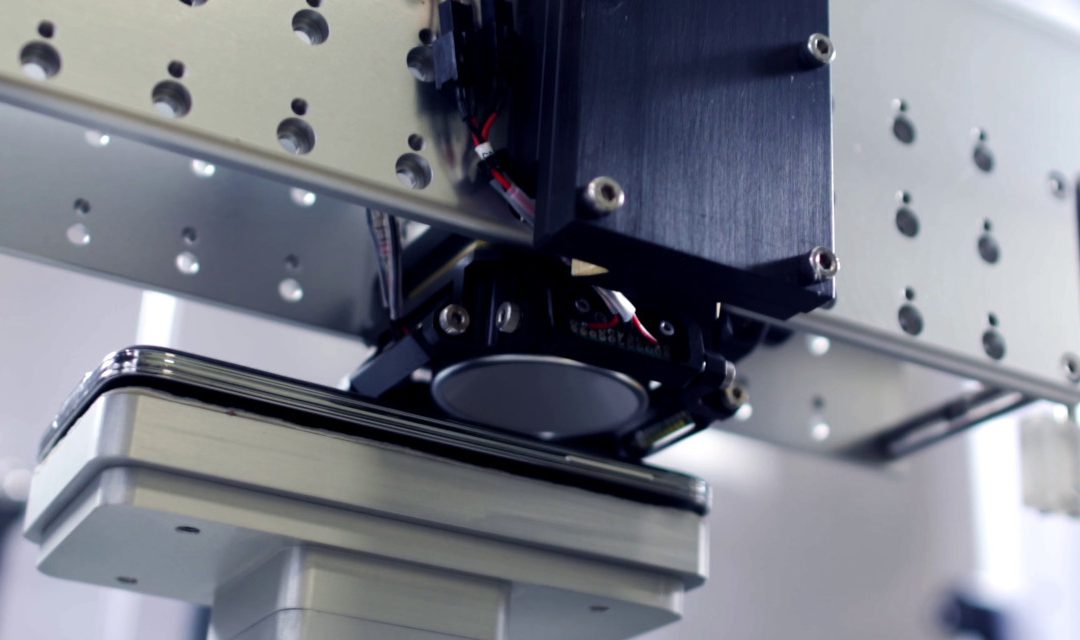

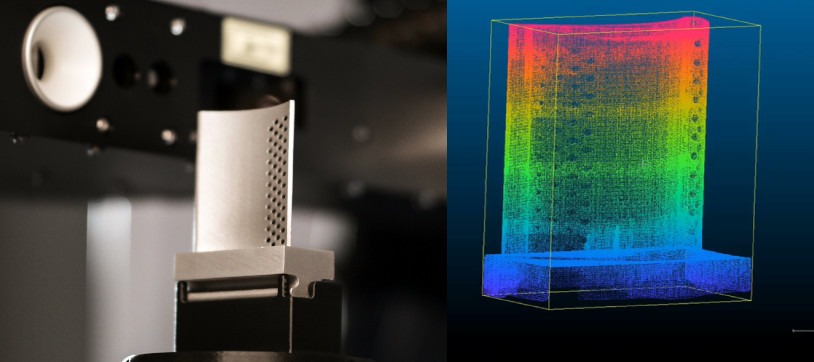

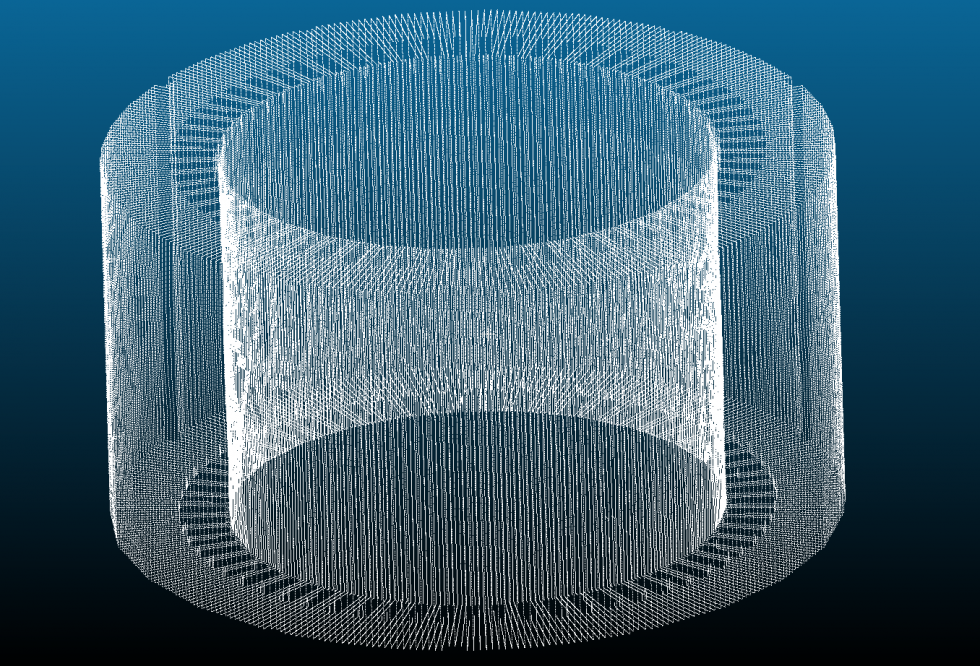

Metrology is moving from the lab to the manufacturing line, which brings non-contact techniques, digital twins, and the integrity of point clouds versus discrete measurement data under increased scrutiny. In our last post, we started discussing the Digital Twin....

by maneet@allfriends.studio | Mar 22, 2021 | Lang - EN, Metrology, ZeroTouch

Industrial production technologies are rapidly advancing, and traditional metrology is increasingly turning to non-contact measurement techniques to keep pace. To maintain the higher throughputs required by product demands, production metrology processes are moving...

by maneet@allfriends.studio | Jul 30, 2020 | Inspection, Lang - EN, Metrology

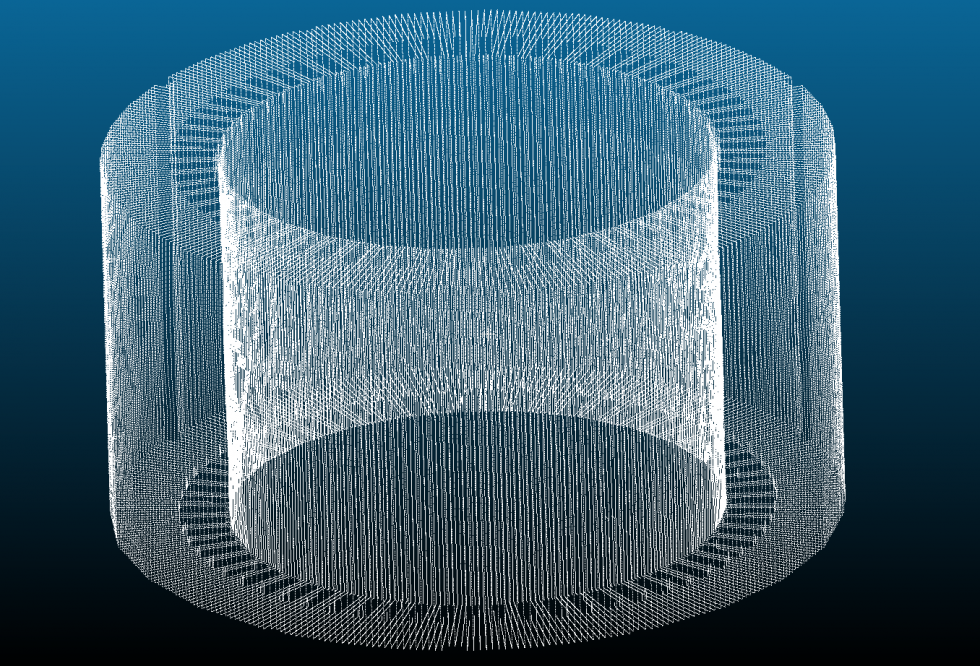

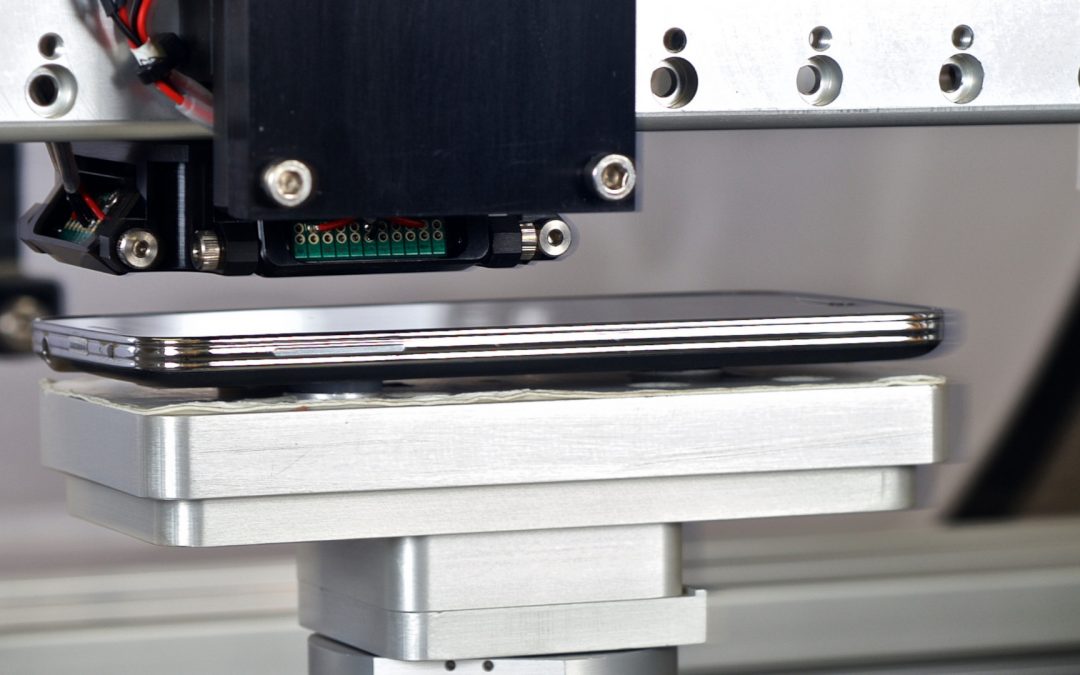

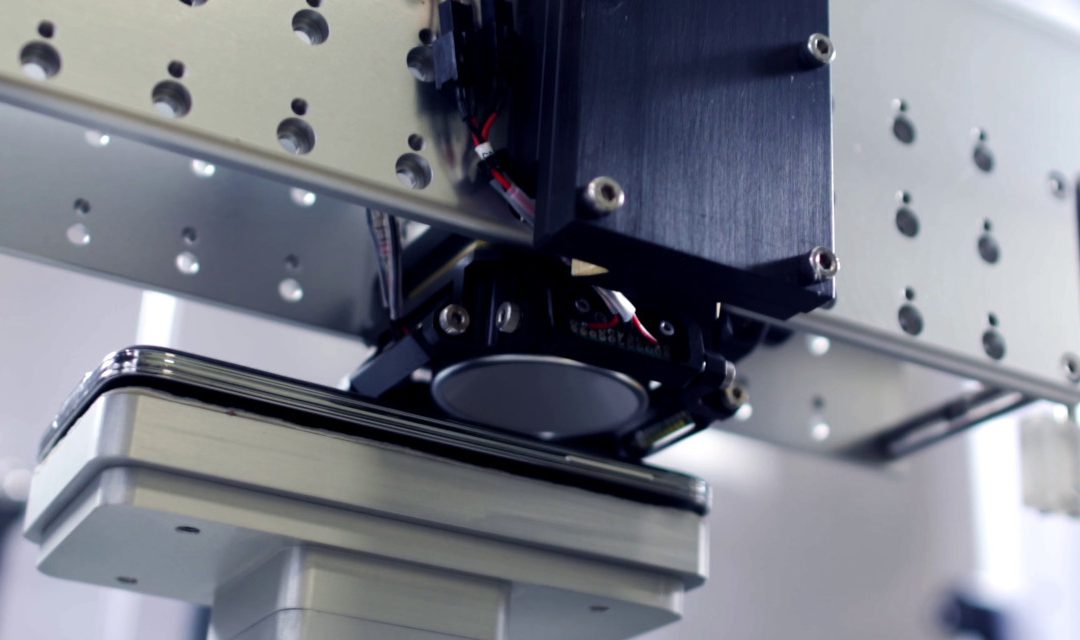

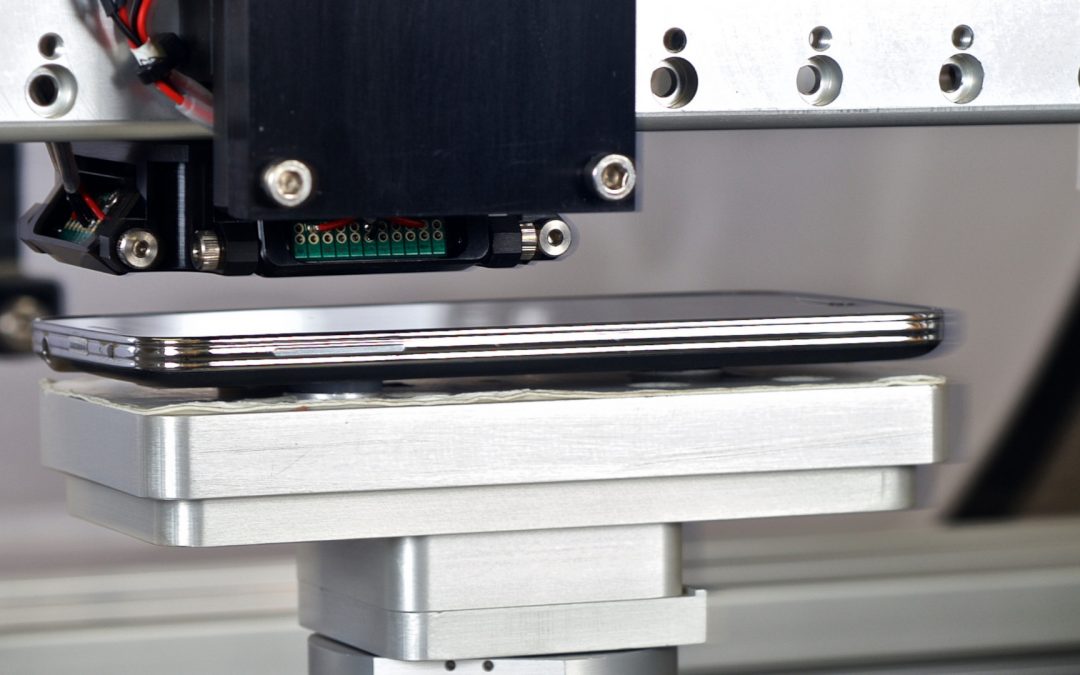

In our last post, we looked at the unique challenges of performing high-speed, quality inspections in high-volume or low-volume/high-mix manufacturing. Today, we examine several use cases where DWFritz employs advanced non-contact technologies to overcome these...

by maneet@allfriends.studio | Jul 17, 2020 | Inspection, Lang - EN, Metrology

Product quality is vital to customer satisfaction, but performing quality inspections in high-volume or low-volume/high-mix manufacturing presents unique challenges that require precision solutions. Without the appropriate systems and tools for performing high-speed...

by maneet@allfriends.studio | Mar 24, 2020 | Automation, Lang - EN, Metrology

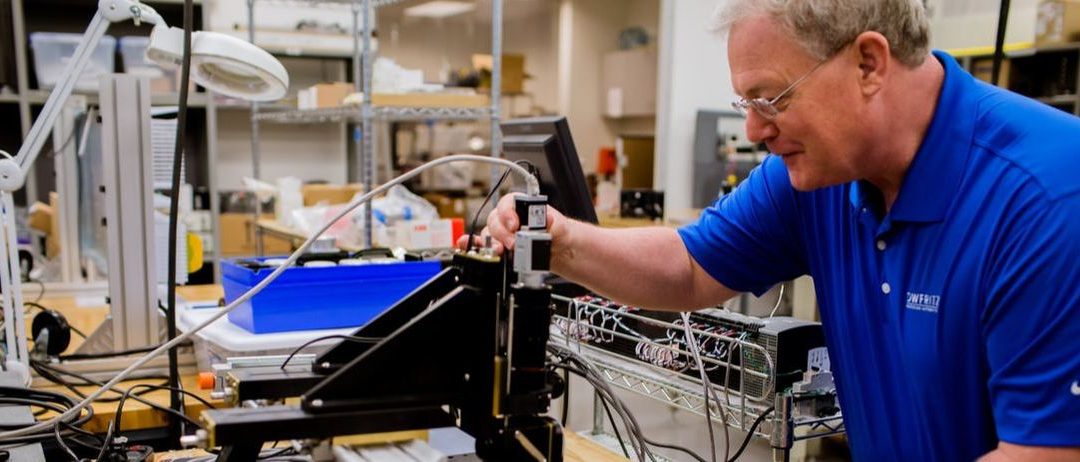

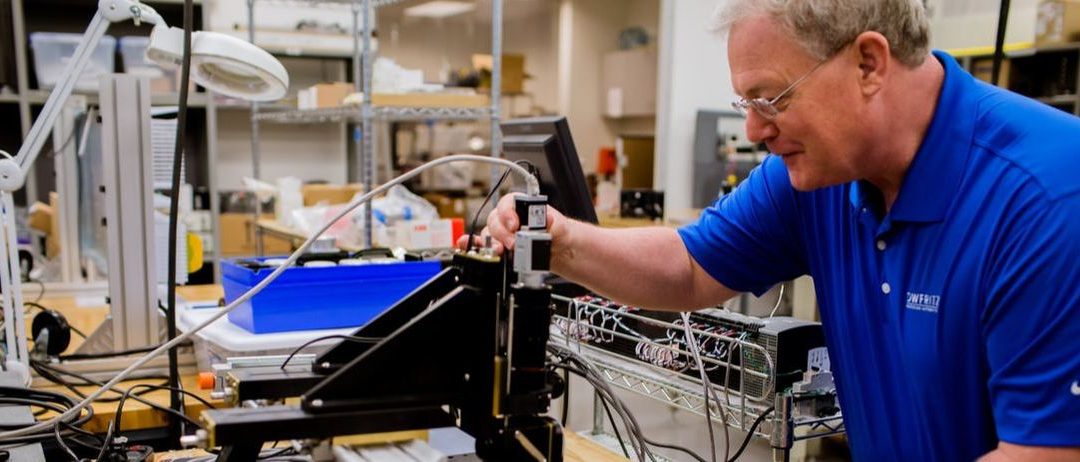

While automating metrology and inspection to improve product quality is not new, the reasons and goals to automate have evolved along with the technology and need. For example, inspection techniques used by contract manufacturers (low-volume/high-mix) versus...

by maneet@allfriends.studio | Jun 30, 2019 | Lang - EN, Metrology, ZeroTouch

In challenging manufacturing environments, 3 key factors influence the long-term performance of automated metrology systems installed in uncontrolled environments. Creating a metrology solution that consistently meets demanding production rates, yields and uptime is...