Our Blog

Get the latest insights and knowledge leadership from our inspection and precision automation experts.

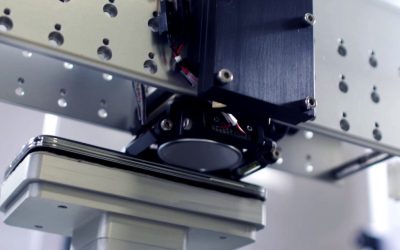

Fully Automated Battery Manufacturing, Part 1

With more than 20 million electric vehicles expected to hit the market by 2030, the automotive industry alone is significantly increasing demand for new products and technologies in the battery cell market. This rapid market expansion will present manufacturers with...

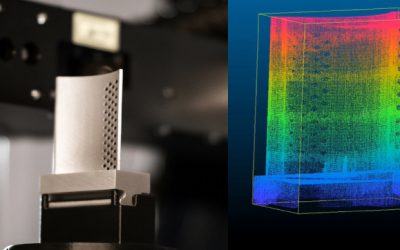

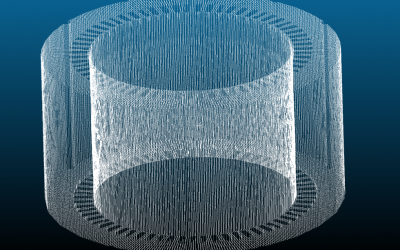

Data Integrity and The Digital Twin, Part 2

Metrology is moving from the lab to the manufacturing line, which brings non-contact techniques, digital twins, and the integrity of point clouds versus discrete measurement data under increased scrutiny. In our last post, we started discussing the Digital Twin....

Data Integrity and The Digital Twin, Part 1

Industrial production technologies are rapidly advancing, and traditional metrology is increasingly turning to non-contact measurement techniques to keep pace. To maintain the higher throughputs required by product demands, production metrology processes are moving...

Responsive, Adaptive, Connected Manufacturing

The time has come for manufacturers, big and small, to understand and embrace the evolving production models, materials, and technologies of smart factories. Industry 4.0 is helping manufacturers increase business value by enabling a more connected, cost efficient,...

How to Ensure Success in Automating Complex Dispensing Applications

Automating precision solutions that overcome complex challenges and consistently meet demanding production goals is no small feat. When that solution requires a complex dispensing application, the task becomes exponentially more challenging. Using a first principles...

Ensuring Pharmaceutical and Medical Inspection Compliance with Machine Vision

Machine vision offers an accurate and efficient method of inspecting package seals in medical and pharmaceutical manufacturing, providing companies a means to comply with device testing regulations and avoid costly recalls. In this article, we cover real-life examples...

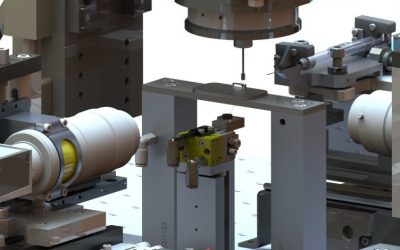

Overcoming Challenges in High-speed Inspection Using Non-contact Metrology, Part 2

In our last post, we looked at the unique challenges of performing high-speed, quality inspections in high-volume or low-volume/high-mix manufacturing. Today, we examine several use cases where DWFritz employs advanced non-contact technologies to overcome these...

Overcoming Challenges in High-speed Inspection Using Non-contact Metrology – Part 1

Product quality is vital to customer satisfaction, but performing quality inspections in high-volume or low-volume/high-mix manufacturing presents unique challenges that require precision solutions. Without the appropriate systems and tools for performing high-speed...

Risk Mitigation: From Concept to Production

Risk can be defined as the possibility that an event could adversely affect the achievement of an objective. Automating precision solutions is, in and of itself, a process of identifying, managing, and reducing risk for our clients. The “problem” isn’t taking on risky...