by maneet@allfriends.studio | Jul 17, 2020 | Inspection, Lang - EN, Metrology

Product quality is vital to customer satisfaction, but performing quality inspections in high-volume or low-volume/high-mix manufacturing presents unique challenges that require precision solutions. Without the appropriate systems and tools for performing high-speed...

by maneet@allfriends.studio | Jun 30, 2019 | Inspection, Lang - EN, Metrology

In the precise world of high volume manufacturing (HVM), microns and milliseconds matter when inspecting medical staples, fitness trackers and smartphones to meet either government regulations or consumer standards. The need for 100% inspection of parts is driving the...

by maneet@allfriends.studio | Jun 30, 2019 | Inspection, Metrology

Understanding the features of a non-contact metrology platform versus a traditional contact coordinate measuring machine (CMM) can help manufacturers choose the right equipment for inspection. By investing in the right inspection technology, manufacturers can improve...

by maneet@allfriends.studio | Jun 30, 2019 | Inspection, Lang - EN, Metrology

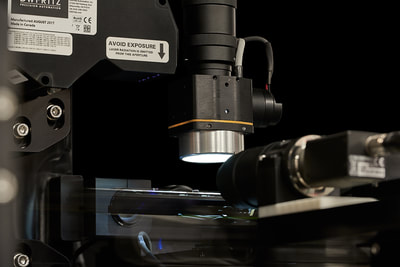

In surface morphology inspection, non-contact optical methodologies provide the same measurement results as a conventional contact profiler, but in a fraction of time. Surface finish quality matters in many industries, especially when consumer health and costly...

by maneet@allfriends.studio | Jun 30, 2019 | Inspection, Lang - EN, Metrology

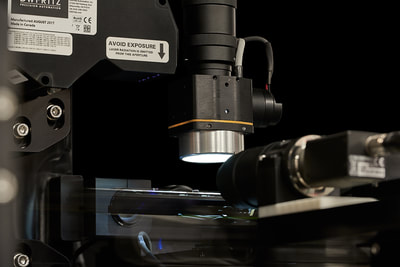

When high volume manufacturers need 100% inspection of parts, non-contact metrology stage design should not only maximize sensor use, but also easily measure different parts on the same system. Whether it’s ensuring smartphones perform to meet customer satisfaction or...