by maneet@allfriends.studio | Jun 30, 2019 | Inspection, Lang - EN, Metrology

In surface morphology inspection, non-contact optical methodologies provide the same measurement results as a conventional contact profiler, but in a fraction of time. Surface finish quality matters in many industries, especially when consumer health and costly...

by maneet@allfriends.studio | Jun 30, 2019 | Inspection, Lang - EN, Metrology

When high volume manufacturers need 100% inspection of parts, non-contact metrology stage design should not only maximize sensor use, but also easily measure different parts on the same system. Whether it’s ensuring smartphones perform to meet customer satisfaction or...

by maneet@allfriends.studio | Jun 30, 2019 | Inspection, Lang - EN

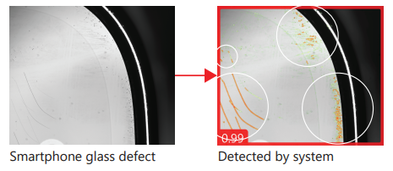

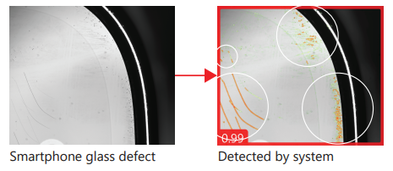

Using deep learning, smart machine vision systems can inspect complex surfaces and parts for cosmetic defects, increasing manufacturing productivity and throughput. Automated cosmetic defect inspection can be challenging — past efforts with computer vision required...

by maneet@allfriends.studio | Jun 30, 2019 | Inspection, Lang - EN, Metrology

Speed, precision measurements and real-time data from non-contact metrology platforms make a difference in reducing scrap and improving yield for high volume consumer electronics manufacturers. In contract manufacturing, 100% inspection is common, but measuring high...

by maneet@allfriends.studio | Jun 30, 2019 | Inspection, Lang - EN, Metrology

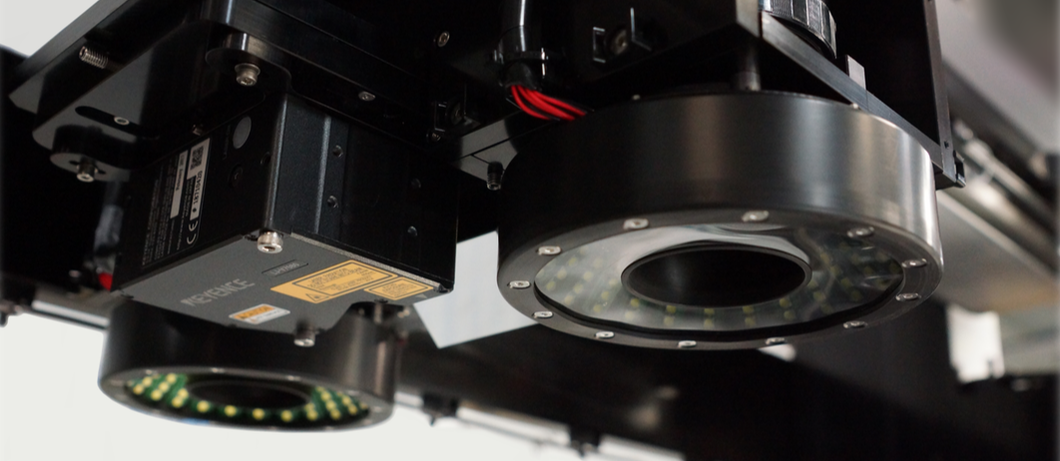

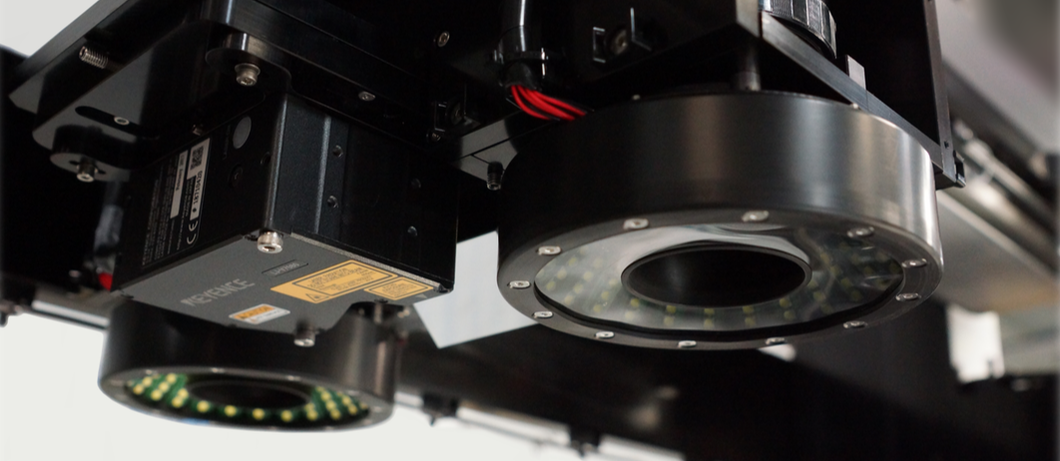

Lighting and timing are key factors when measuring parts in high speed motion. By using short bursts of high intensity lighting, the vision system effectively freezes the motion for inspection. Lighting and timing are key factors when measuring parts in high speed...