Quality. Precision. Innovation.

Whether you need an automated, high-speed assembly or inspection solution, or a contract manufacturing partner, we’ve got you covered.

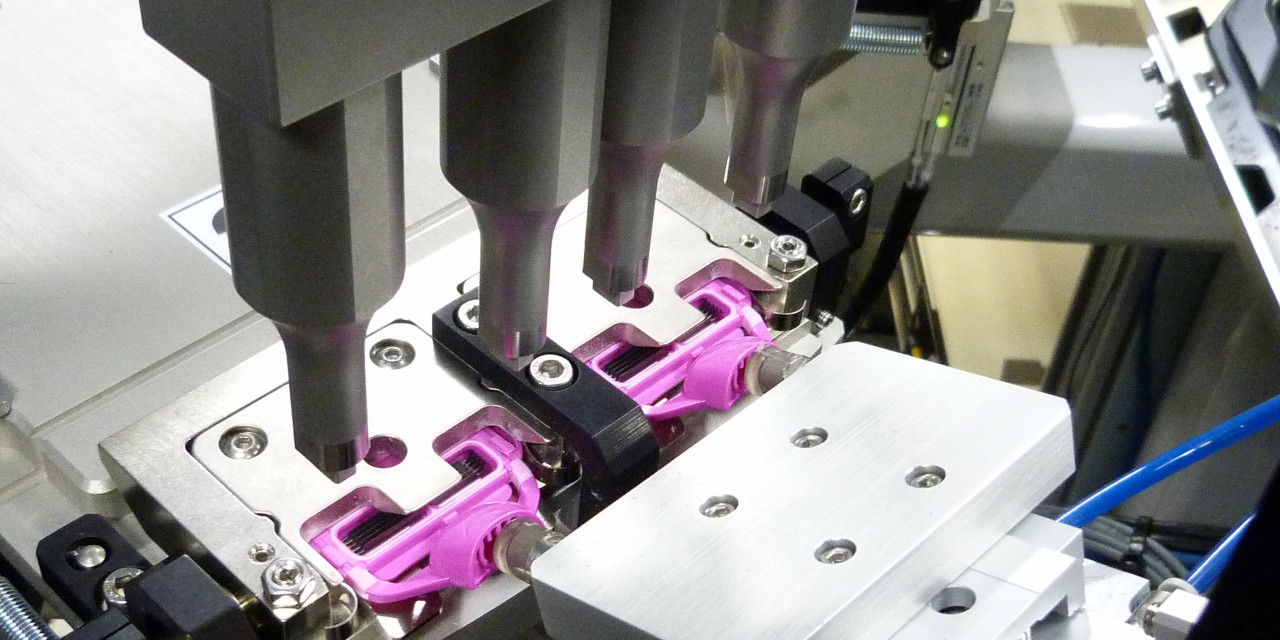

Precision Automation Capabilities

From high-speed metrology and defect detection to process automation and material handling, we excel in precision engineering solutions for complex manufacturing challenges.

Engineer-to-Order Solutions

We design, build, and support innovative engineer-to-order precision automation systems to solve our customers most complex advanced manufacturing challenges.

Build-to-Print Services

Bring your designs to life through our global build-to-print services, and benefit from our world-class production technicians, global supply chain partnerships, MRP-inventory controls, and more.

Ready To Get Started?

Research and Development

To enable our cutting-edge designs, our facility houses a state-of-the-art engineering lab, optimized and equipped to support our innovative and compelling platform solutions.

- Rapid Proof of Principle (PoP) development

- Component qualification & calibration

- Advanced machine vision, lighting, design & testing

- 2D and 3D inspection of customer parts

- Machine vision camera and 3D sensor testing, and application development

- Rapid prototyping using 3D printers

- Software development

- Defect detection using deep learning

- Advanced high-speed metrology product & platform development

Technical Expertise

Our world-class engineers stay current on the latest technological developments, including the most cutting-edge materials and processes. Our technical expertise includes:

- Custom controls software

- 2D and 3D vision multi-sensor analysis

- 3D data analysis

- Defect detection using deep learning

- Rapid data acquisition and processing

- Precision motion control (PC- and PLC-based architecture)

- Customizable GUI development including SPC charts

- Clean room equipment design

Process & Performance

We follow a rigorous development process that minimizes risk and ensures exceptional performance. Using a collaborative approach between our team and yours, our PMP-certified project management team effectively capture project scope, investment, and timeline.

- Rigorous risk management process that includes feasibility studies, risk identification, and recommended alternate manufacturing strategies.

- Professional project management, supply chain, sales, service, and operations teams support every project, from launch through installation and validation.

- Employing standard tools, forms, and reports for scope management, scheduling, budget and cost estimates, monitoring, and control of project gates.

- Driving performance through instilled disciplines for consistency and efficiency.