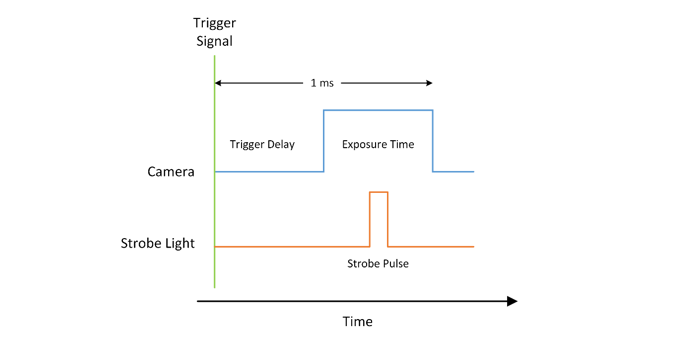

An encoder-based signal triggers the camera to expose its sensor, followed by the strobe light.

Choosing the Right Lighting for the Job

A part’s surface optical properties, such as color, finish and transparency, as well as part features like size and shape will determine lighting selection. Measurement, inspection and throughput requirements also play a critical role in identifying illumination schemes.

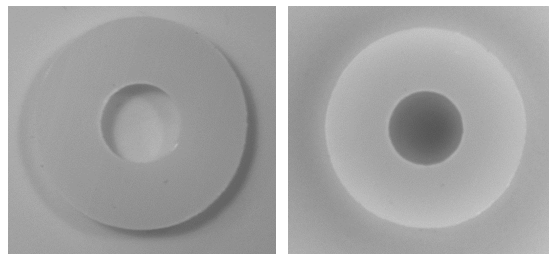

Before deciding whether to use a backlight, coaxial, dome or ring light, it’s important to analyze whether the lighting will be used in an on-axis or off-axis configuration, according to Photonics.

On-axis (bright field) illumination provides even, flat diffuse illumination, which is important when illuminating flat nonreflective surfaces, such as metal, glass and plastic. Dome lights are commonly used as bright field components, while coaxial illuminators are often used as partial bright field components. On-axis configurations also can include spotlights, line lights and ring lights. On highly reflective surfaces, an on-axis light may just provide an image of the light itself.

Off-axis (or dark field) lighting reflects much of the incident light away from the camera lens. Edges or scratches on part surfaces reflect the light, while flat, polished surfaces remain dark. In dark field lighting, low angle lighting can illuminate the object from either single or multiple directions to cast shadows for specific edges.

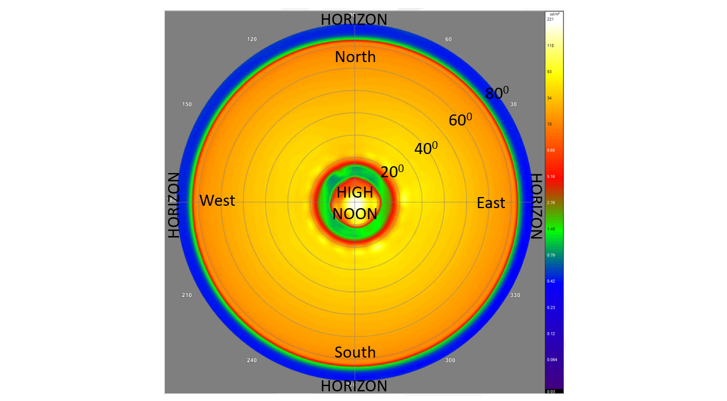

Oftentimes different parts and inspections require different illumination angles. The directionality and uniformity of angles affect the appearance of the features. To find the ideal lighting, it helps to analyze the light from the perspective of the region of interest (ROI) on the part.

Imagine an ant resting on the center of a stationary part on a metrology platform, just a few millimeters below an LED light array. What would the ant “see” when looking up at the sky? This ant’s eye view illustrates that there is a big difference between illuminating a part with a 45° sunrise light versus a high noon collimated coaxial shot versus a uniform cloudy day dome illumination. In the ant’s eye view, a perfect collimated coaxial light would produce a small spot at high noon. The ideal cloudy day dome light should be uniform from horizon to horizon.