Automating advanced manufacturing systems is a complex process that requires careful planning and execution. The right time to automate will depend on several factors, including the nature of the products being manufactured, the size and complexity of the factory, and the availability of appropriate technology and expertise. A phased approach to automation, starting with the most critical processes, may be the most effective way to achieve success.

The key requirements for executing a precision automation project are clear project objectives, expertise and proper resources, robust technology, planning and risk mitigation, and collaboration and flexibility.

Clear Project Objectives

Clear and well-defined objectives are critical for any automation project. Your objectives will keep the project on track to achieve the desired outcomes. Defining objectives includes identifying the specific processes to automate, the desired outcomes (e.g., increased efficiency, reduced costs, improved quality), and the timeline for completion.

When defining these objectives, consider the following factors:

- Business goals: Align the automation project with the organization’s overall business goals, such as increasing efficiency, improving quality, reducing costs, and enhancing competitiveness.

- Processes to automate: Define the specific processes to automate and the desired outcomes for each process – for example, the expected improvements in efficiency, quality, and throughput.

- Timeline: Develop a comprehensive timeline to complete the automation project. The timeline should include milestones and deadlines for key project stages, including design updates, material procurement, system build, factory acceptance testing, and installation.

- Budget: Clearly define the project budget, including the equipment costs, installation, training, and ongoing support and maintenance.

- Performance metrics: Establish measurable performance metrics to evaluate each stage of the project, as well as the end results.

Objectives provide a roadmap for the project, ensuring all stakeholders are working towards the same goals. Be sure to regularly review and update the objectives to keep the project on track for a successful outcome.

Expertise and Resources

Automating a factory requires specialized expertise in areas such as engineering, robotics, material handling, machine vision, control systems, and software development. A precision automation partner such as DWFritz can deliver the necessary skills and experience to execute an advanced manufacturing automation project.

A precision automation partner brings significant technical expertise in critical areas, such as custom control software, machine vision systems, 3D data analysis, defect detection using deep learning, precision motion control, full-line assembly systems, advanced dispense processing, and much more. By leveraging established global relationships with technology vendors and suppliers, your system will include innovative designs, built with the latest technology, and employing best practices. With a well-developed supply chain and proper technology partners, your precision automation partner can provide a range of services, from system design and build through installation and ongoing support.

Beyond the actual design and build of your automation system, your automation partner can provide a clearer understanding of the expertise required for the project and ensure the right resources are in place to complete the project successfully.

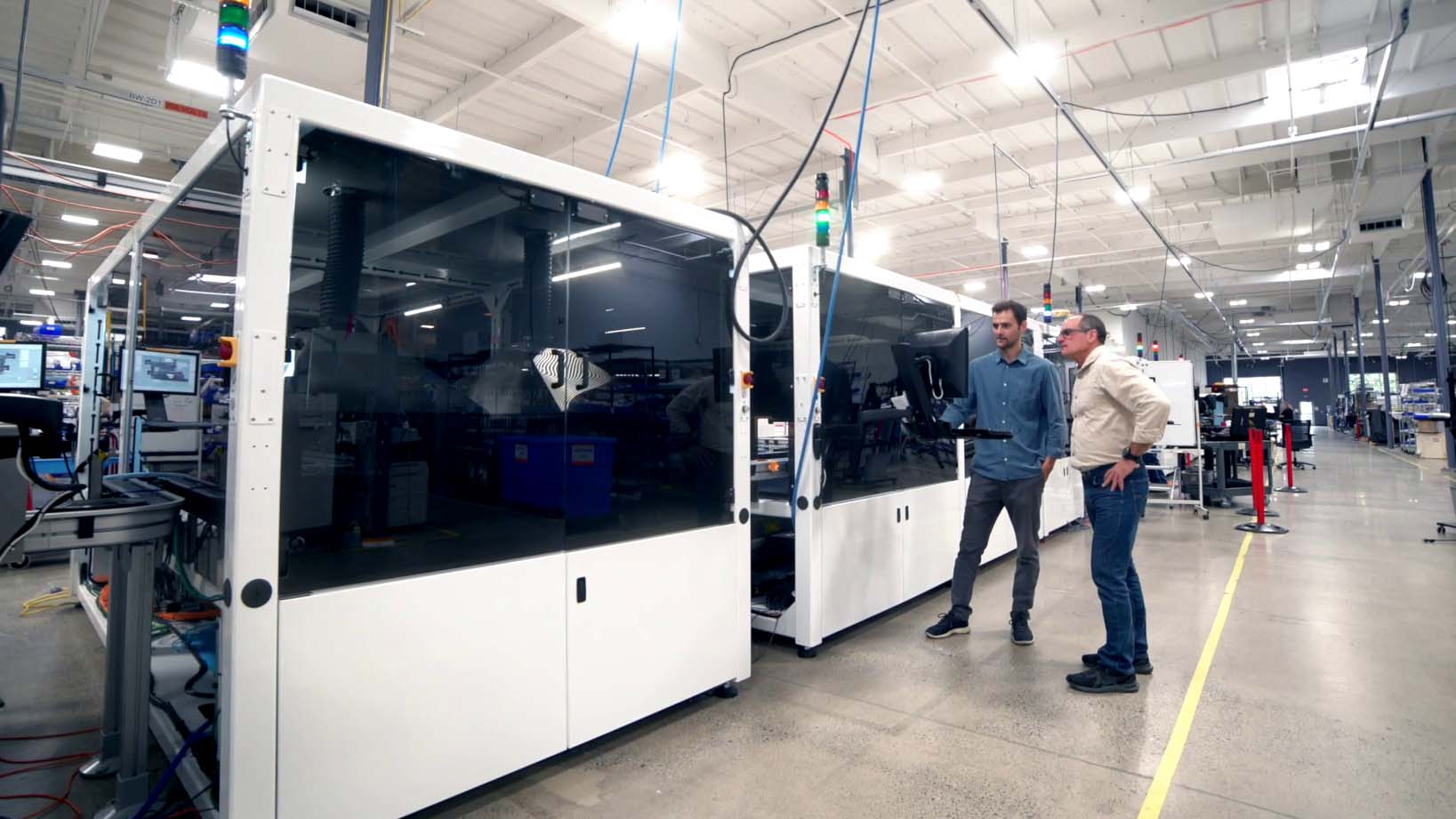

Automated modular battery cell processing and assembly system that is scalable to various cell form factors and throughputs.

Robust Technology

Precision automation projects require robust and reliable technology, including automation equipment, control systems, and software. Carefully select technology that it is appropriate for the specific requirements of the project and is compatible with the factory’s existing systems and infrastructure. Additional factors to consider when selecting the appropriate technology include the size and complexity of the system, the type of manufacturing processes involved, and the desired current and future outcomes.

Automation equipment and systems may be used in harsh industrial environments, so care should be taken to select technology that is reliable, durable, and includes support or maintenance services. This will help ensure that the system continues performing as required over time, minimizing the risk of downtime and maintenance costs for spare parts and technical support.

Any new technology, whether custom designed or off-the-shelf, must be compatible with the factory’s existing systems and infrastructure, including control systems, software, and data networks to minimize any risk.

Planning and Risk Management

Precision automation projects require careful planning to coordinate all aspects of the project, including design of the automation systems, installation of equipment, and training of operators and maintenance personnel. Automation projects can involve significant risks, such as technical challenges, schedule delays, and cost overruns, making a risk management plan critical for identifying and mitigating these risks before they happen. Such plans can be used to develop contingency plans for unexpected events as well.

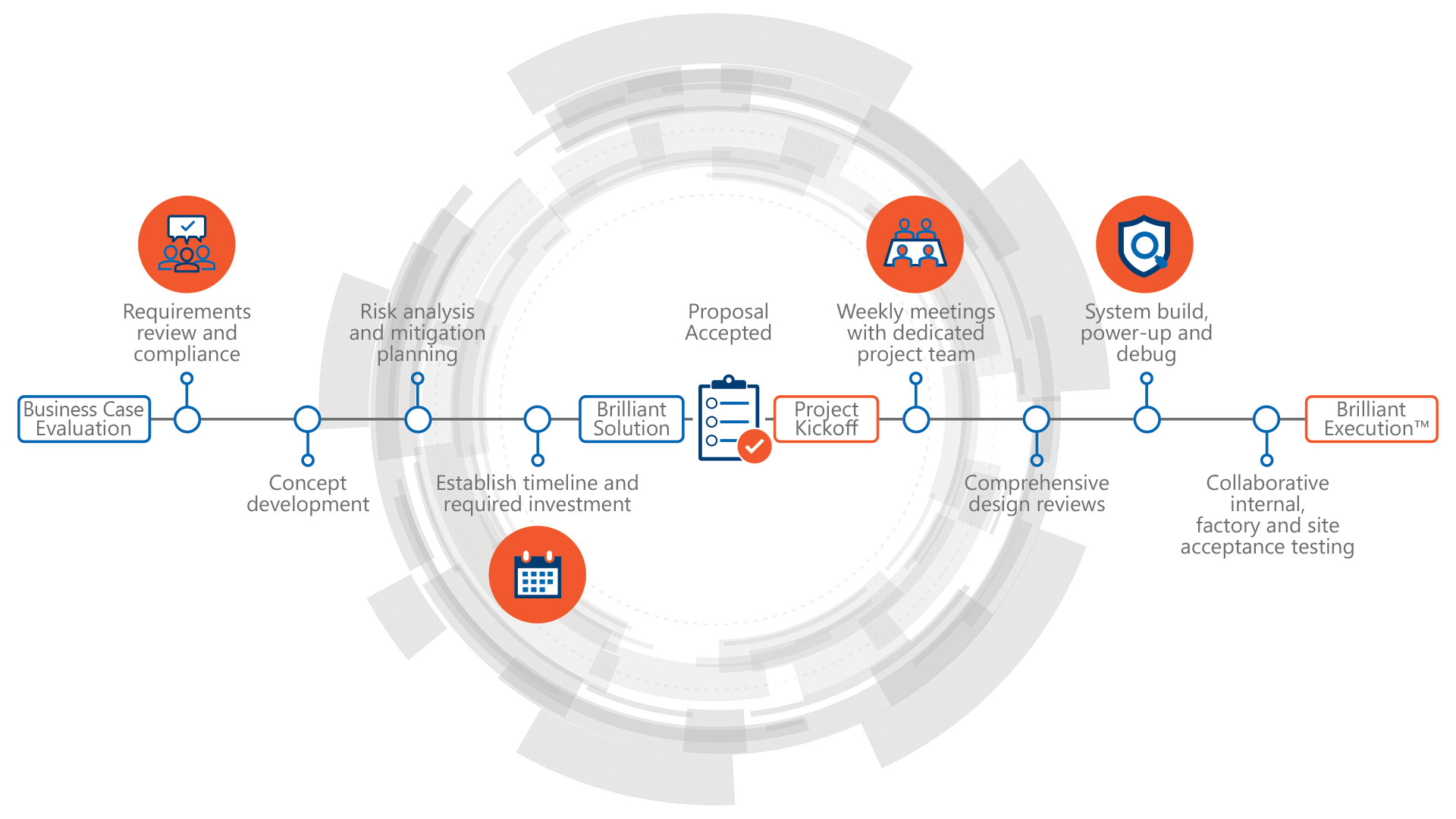

At DWFritz, we follow a rigorous development process to minimize risk and ensure exceptional performance. Using a collaborative approach between our team and yours, our PMP-certified project management team effectively captures project scope, defines investment, and develops a timeline. The project team – which includes the key stakeholders, project managers, engineers, technicians, and software developers – are tasked with establishing a well-defined project scope, including the processes to be automated, the desired outcomes, and the timeline for the project.

Be sure to establish realistic estimates of the time required to complete each stage of the project when developing the project schedule. Additionally, ensure the project budget is based on realistic cost estimates to complete the project, including costs for equipment, installation, and training.

A risk management plan must be developed, including a comprehensive assessment of the potential risks associated with the project. DWFritz employs a rigorous risk management process that includes feasibility studies, risk identification, and recommended alternate manufacturing strategies. Our robust risk management strategy includes an ongoing process of identifying, prioritizing, and resolving risks that could impact the success of the project.

Using a collaborative approach between our team and yours, our PMP-certified project management team effectively capture project scope, investment, and timeline.

Collaboration and Flexibility

Collaboration and flexibility are important components of executing a precision automation project. Collaboration keeps all stakeholders working together effectively, while flexibility ensures that the project can respond to changes and challenges as they arise.

Collaboration between the different stakeholders involved in the project, including the client, engineering team, and vendor partners, is critical to the success of any project. Effective communication and coordination sures that everyone is working towards the same objectives and on the same timeline.

Flexibility allows the project to respond to changes and challenges as they arise. For example, the automation system may need to accommodate changes in the manufacturing process or to accommodate innovative technologies. Building such flexibility into a system from the beginning allows the automation system to evolve and adapt, allowing for future changes and upgrades and ensuring that the investment in automation remains relevant and effective over time.

Achieving effective collaboration and flexibility in a precision automation project requires the right tools and processes in place. At DWFritz, we employ standard tools and software designed for collaboration, as well as processes for regular communication and updates, monitoring, and reviewing project requirements on an ongoing basis.

Executing a precision automation project involves careful planning, collaboration, and a commitment to quality and continuous improvement. The right combination of expertise, technology, and project management can help ensure the success of the project and deliver the desired outcomes.