Criteria to Consider When Evaluating a Contract Manufacturer’s Competency, Part 2

Criteria to Consider When Evaluating a Contract Manufacturer’s Competency, Part 2

Welcome to the second installment of our deep dive into Build-to-Print (BTP) with DWFritz Automation. As we further explore the intricacies of BTP, it’s crucial to have a well-rounded understanding. If you haven’t had a chance to review Part 1 of our series, we highly recommend checking it out for foundational insights.

Key Considerations in Selecting a Contract Manufacturing Partner

1. Cultural Fit: Relationship building is essential when embarking on business in a new region with an original contract manufacturer as it presents unique challenges. Companies must anticipate the cultural nuances and the time investment required to foster and solidify these emerging relationships. For smooth communication and long-term success, it’s crucial that the cultures of both companies align with one another.

2. Past Projects: Evaluating a contract manufacturer’s product portfolio offers insights into their past projects and expertise. If their history showcases products aligned with yours, it’s a strong indication of their capabilities. Such alignment typically ensures a smoother production process, reducing potential hiccups and ensuring higher efficiency in the final product.

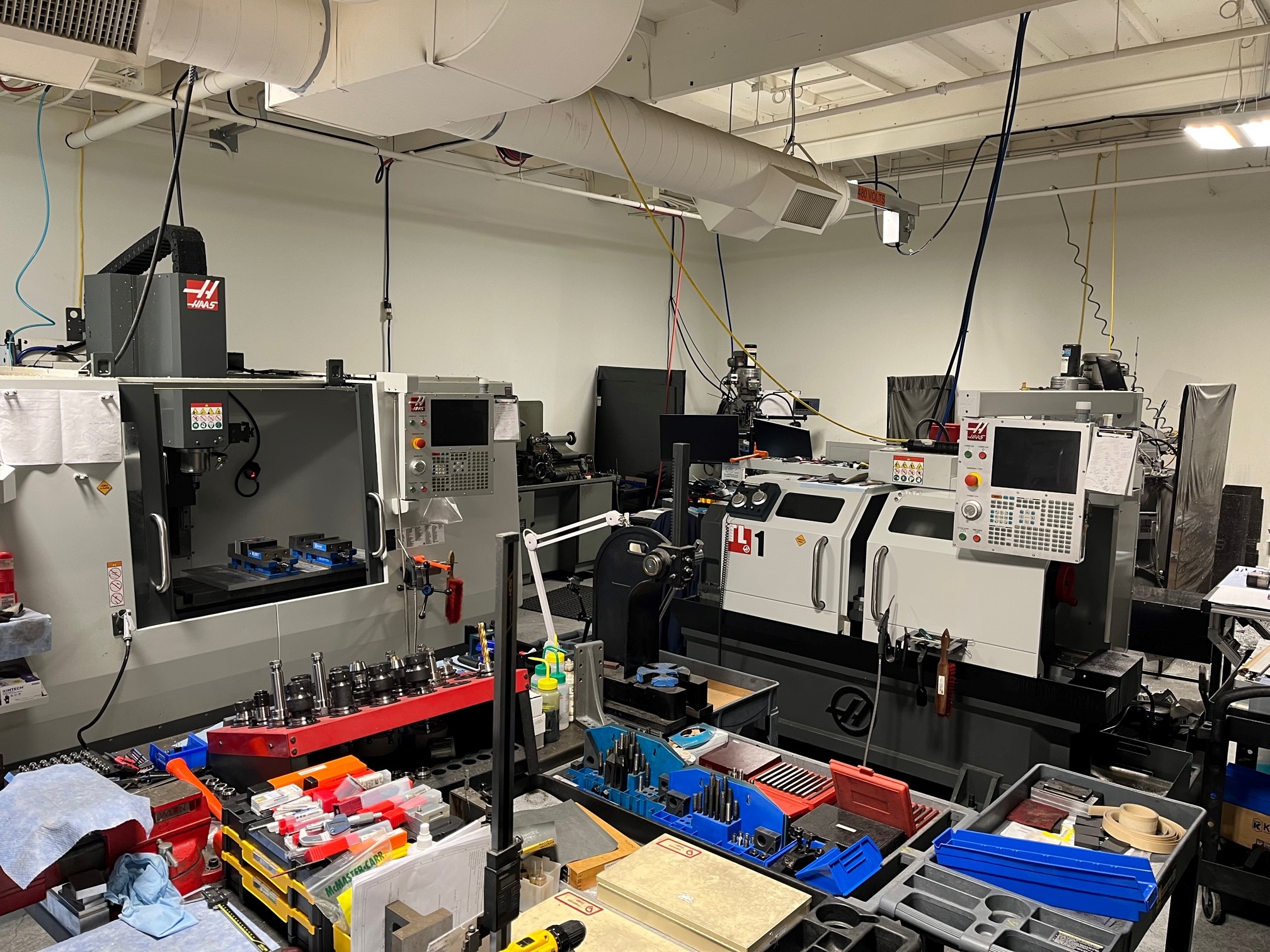

3. In-house Machining & Labs: A contract manufacturer that can promptly handle urgent requests showcases their agility and dedication to client needs. At DWFritz, our in-house machine shop allows us to have Quick Turn capabilities, ensuring swift rectifications of material malfunctions rather than enduring prolonged return & reorder processes. Regular tool audits further signify our commitment to quality. Our machine shop is also equipped with state-of-the-art CNC’s and 3D printing capabilities. In addition, we also have an in-house engineering R&D lab to help our clients prototype their designs while in our calibration lab, we have the ability to test, measure, and calibrate various equipment.

4. Ability to Scale: In choosing a contract manufacturer, consider their scalability and adaptability. Their level of automation hints at efficiency, while company size indicates current capacity and growth potential. Volume discounts suggest cost benefits for large projects, and available expansion space signals readiness for future demands. These factors collectively gauge the manufacturer’s suitability for both immediate and long-term needs.

5. Logistics Expertise: For companies looking to seamlessly navigate the global marketplace consider a contract manufacturers’ shipping logistics. A CM’s prowess in import/export logistics is invaluable. This expertise, combined with access to diverse transportation modes-land, ocean, and air-ensures that products can be efficiently shipped and received across various routes. Their ability to handle these logistics reduces potential bottlenecks, ensuring smooth operations and timely deliveries.

6. Global Supply Chain: It is crucial for a contract manufacturer to have an efficient and exceptional supply chain. At DWFritz, our ability to produce multiple components in-house is a testament to our streamlined operations and operational efficiency. Adding to this, we offer 3D printing capabilities, giving us greater flexibility to meet client specifications swiftly. Moreover, our focus on regional sourcing enhances our ability to deliver quick production cycles while minimizing potential delays. Through this balanced approach of in-house production, regional sourcing, and 3D printing capabilities, we are committed to maintaining both product consistency and efficient logistics.

FREE 100 – Point Checklist – Questions to Ask When Evaluating a Contract Manufacturer

As we wrap up Part 2, our journey into the world of contract manufacturing is far from over. In Part 3, we’ll continue to unravel more layers, offering deeper insights and essential factors to consider. Journey with us to the next segment and refine your understanding even further.

The picture above is an example of a BTP project done by DWFritz. The case study goes into detail how DWFritz manufactured a medical device package and label inspections to increase reliability, decrease costs, and dramatically reduce contamination rinks.