Many medical device manufacturers are finding that automated seal inspection improves sterile package reliability, decreasing packaging failure, product contamination and costly recalls.

Sterile packaging of medical devices is critical for patient health and safety. Whether it’s packaging for a surgical instrument, joint prosthesis or a heart valve, broken packaging seals can cause product contamination. Other sealing applications, including food and military supplies, also rely on intact hermetic seals. The common link between these applications is that failure of a seal can have serious consequences, such as infection or even loss of life.

“It goes without saying that Class II and III medical device and supply manufacturers can ill afford the risk of sterile product contamination,” said John Fouts, senior controls software engineer at DWFritz, in Vision Systems Design Magazine.

And yet, FDA recalls show that current approaches to package sealing are inadequate. Sterility issues caused 89.4% of recalled medical device units in the third quarter of 2017, according to the Stericycle Recall Index. One failed package can cause a recall of the entire lot and even close down the manufacturing line, increasing product costs and potentially limiting supplies of critical devices. Lawsuits can further raise the costs associated with failed seals.

Many package seals are inspected by hand, but the time available for this inspection is limited: defects must be detected within 10 seconds.

“Manual inspection of package seals tends to be time consuming and error prone,” said Fouts. “After all, contaminants such as hair and hidden particles in the seal can be extremely challenging for people to see, leading to mistakes or oversights.”

Low-cost automated 100% inspection of seals improves the dependability of shipped packages, dramatically lowering the risk of delivering contaminated materials.

Using Technology to Ensure Seal Reliability

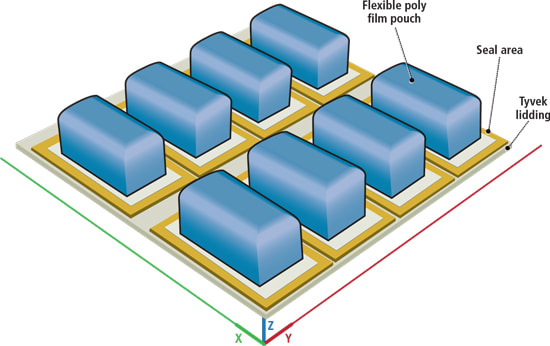

Automated package seal inspection systems use an advanced vision system to verify the package integrity of critical supplies and materials, according to Fouts.

The individual challenges inherent in seal inspection, including shape, transparency and color, require the right light sources and camera setup so that any package seal can be reliably inspected. Cameras can be set up for area or line scans. Images collected during a scan are stitched together to create a single image, which is processed by advanced algorithms to identify defects.

“The image analysis software uses various algorithms to perform certain vision tasks. One identifies channels across the seal and another looks for wrinkles,” said Fouts. Other algorithms detect spoiled seals, glazed seals, hairs and any holes or punctures that may exist.

Lighting is provided by strobes in order to freeze the scan motion of the moving target. Difficult color and transparency situations can be handled with custom lighting that can expose the defects of interest. While most visible defects are detected with high-angle bright-field lighting, tough defects like blond or gray hair on white backgrounds can be picked up using low-angle dark-field illumination. And if visible light isn’t effective for a particular defect, both infrared and ultraviolet lighting options can be used.

Automated seal inspection systems “ensure that sterile products remain sterile throughout the supply chain,” said Fouts. And that’s important for both manufacturers and consumers.