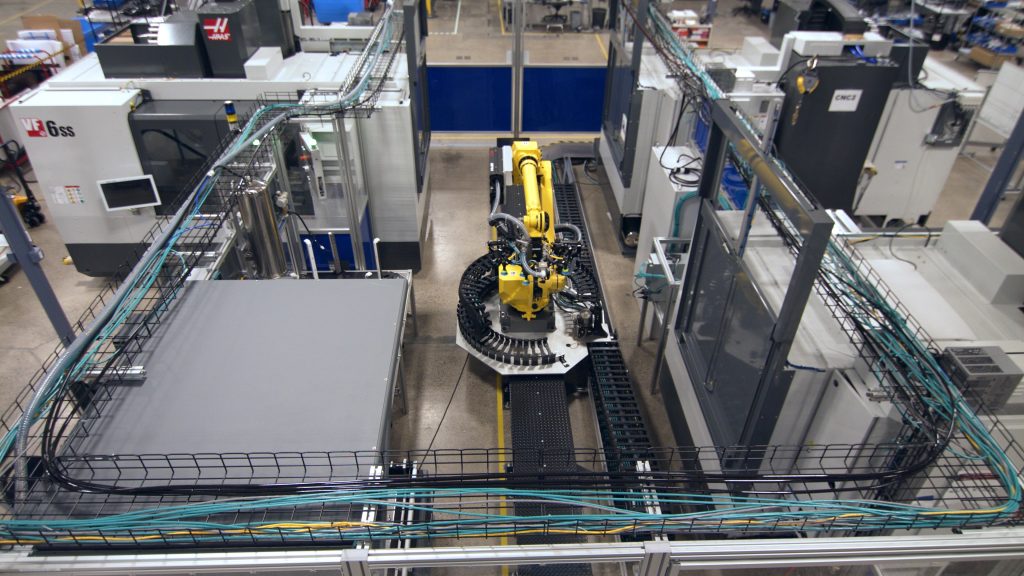

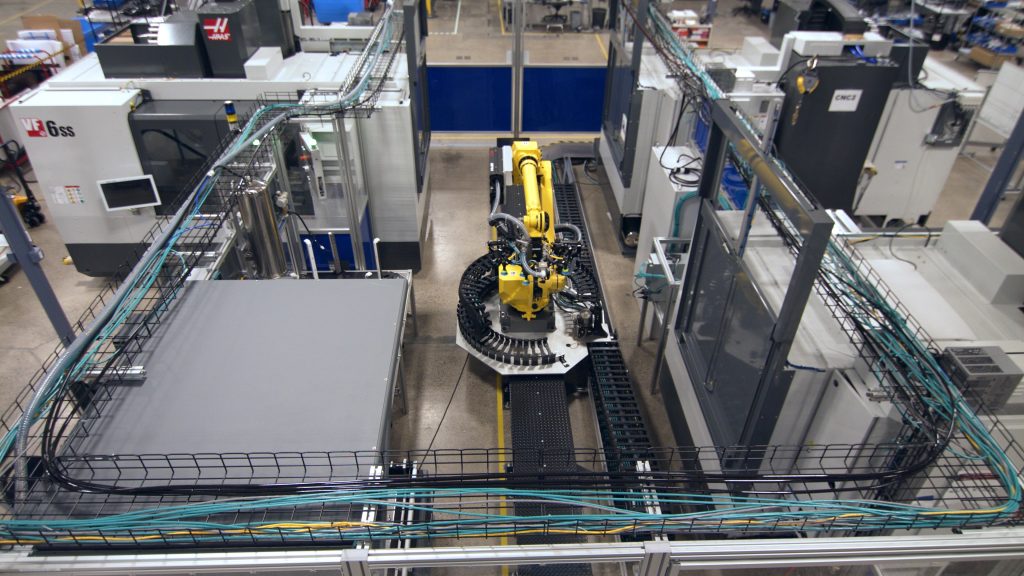

by Laxman | Mar 8, 2023 | Automation, Lang - EN

Automating advanced manufacturing systems is a complex process that requires careful planning and execution. The right time to automate will depend on several factors, including the nature of the products being manufactured, the size and complexity of the factory, and...

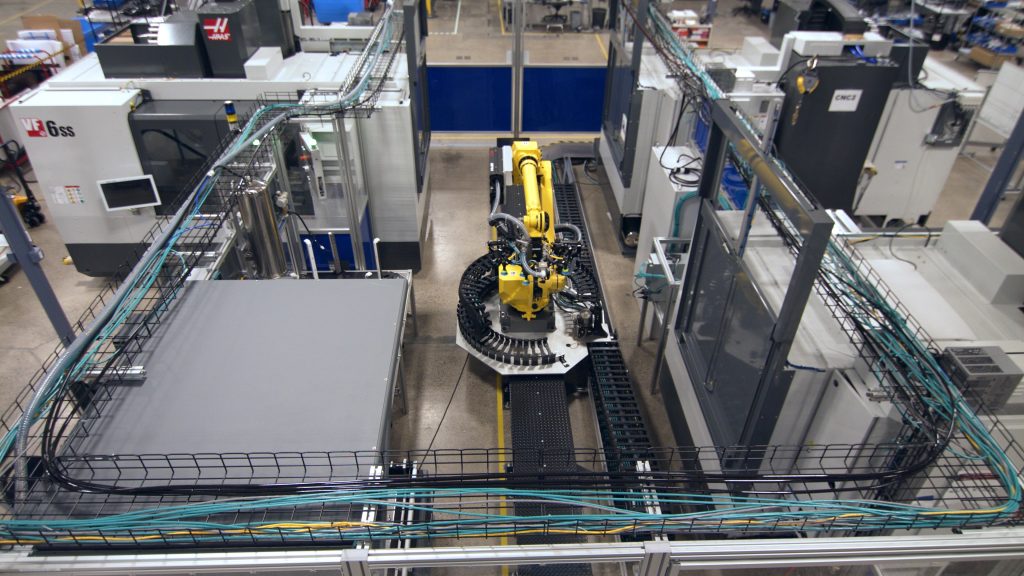

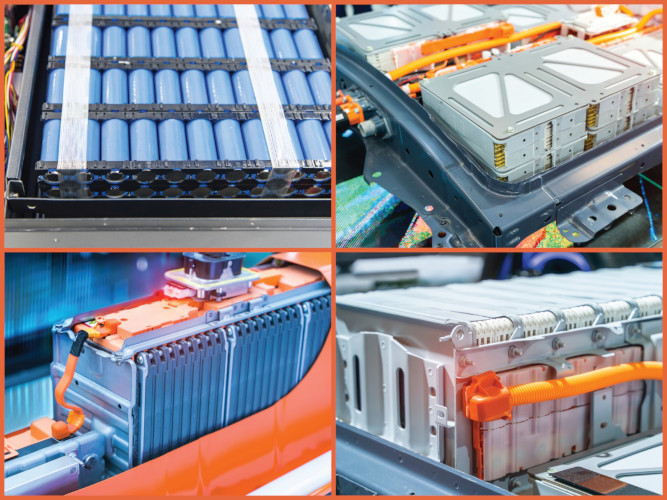

by maneet@allfriends.studio | Dec 29, 2021 | Automation, Lang - EN, Precision Assembly

Manufacturing battery cells is a complex, demanding process with significant challenges. In part 1 of our series, we highlighted the key challenges in developing a fully automated battery manufacturing line. Now, we look at how DWFritz and Bosch-Rexroth partnered to...

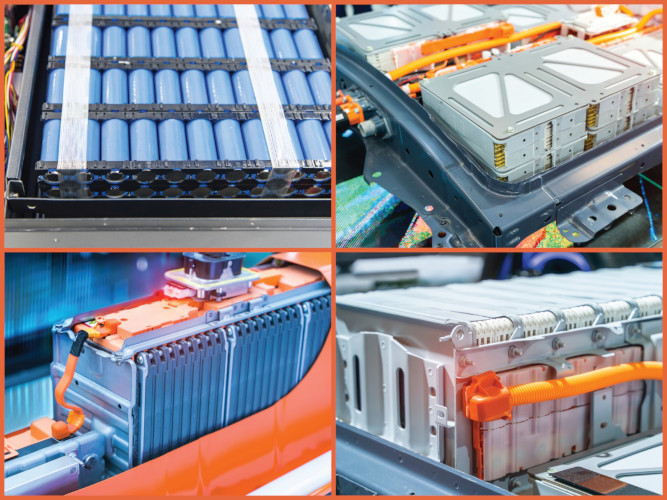

by maneet@allfriends.studio | Jan 28, 2021 | Automation, Lang - EN, Smart Factories

The time has come for manufacturers, big and small, to understand and embrace the evolving production models, materials, and technologies of smart factories. Industry 4.0 is helping manufacturers increase business value by enabling a more connected, cost efficient,...

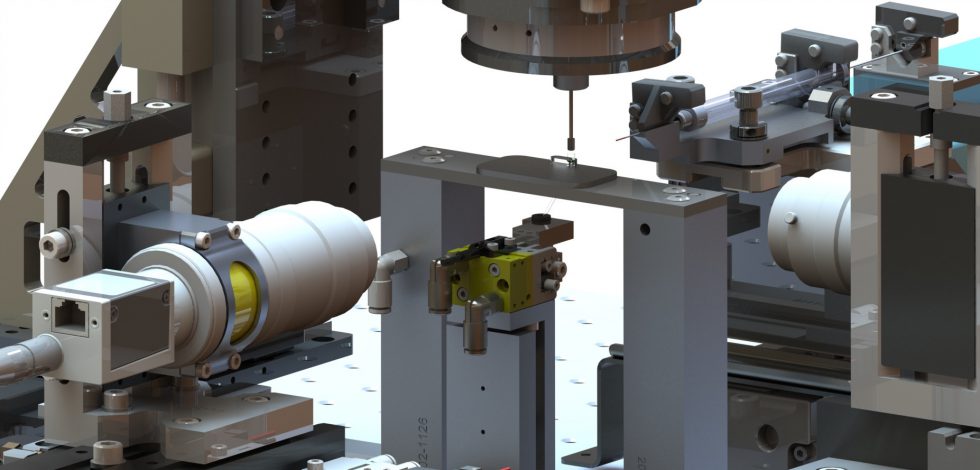

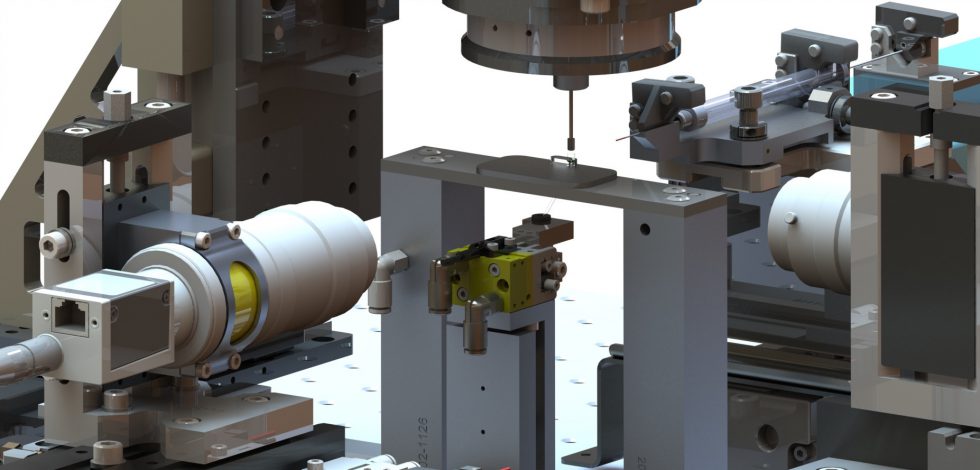

by maneet@allfriends.studio | Nov 11, 2020 | Automation, Lang - EN

Automating precision solutions that overcome complex challenges and consistently meet demanding production goals is no small feat. When that solution requires a complex dispensing application, the task becomes exponentially more challenging. Using a first principles...

by maneet@allfriends.studio | Jun 15, 2020 | Automation, Lang - EN, Project Management

Risk can be defined as the possibility that an event could adversely affect the achievement of an objective. Automating precision solutions is, in and of itself, a process of identifying, managing, and reducing risk for our clients. The “problem” isn’t taking on risky...