Fully Automated Battery Manufacturing, Part 1

Fully Automated Battery Manufacturing Part – 1

With more than 20 million electric vehicles expected to hit the market by 2030, the automotive industry alone is significantly increasing demand for new products and technologies in the battery cell market. This rapid market expansion will present manufacturers with significant challenges, but to overcome these challenges, first we need to identify the critical aspects of battery cell manufacturing.

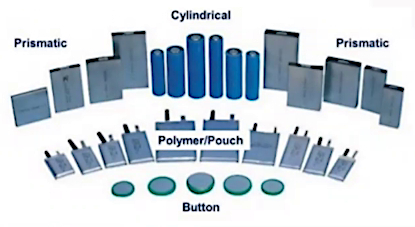

Battery cells come in several form factors, each using very different architectures and chemistry formulations. Even form factors within the same construction geometry can vary significantly, as each one attempts to achieve a higher energy density for more energy storage per package. Though some of the technologies are the same, different battery cells require unique assembly and manufacturing processes, which impacts performance, storage capacity, and the charge/discharge time of the cells.

Beyond battery cell characteristics, automation efforts must consider the manufacturing throughput requirements. Factors that influence these requirements include overall ROI, number of process steps, throughput per cell, conveyance, payload characteristics, system footprint, overall yield, yield per cell, and overall equipment effectiveness. These factors all impact the final cost of the automation solution, driving both the yield and final product quality.

Battery Manufacturing Processes and Assembly Line

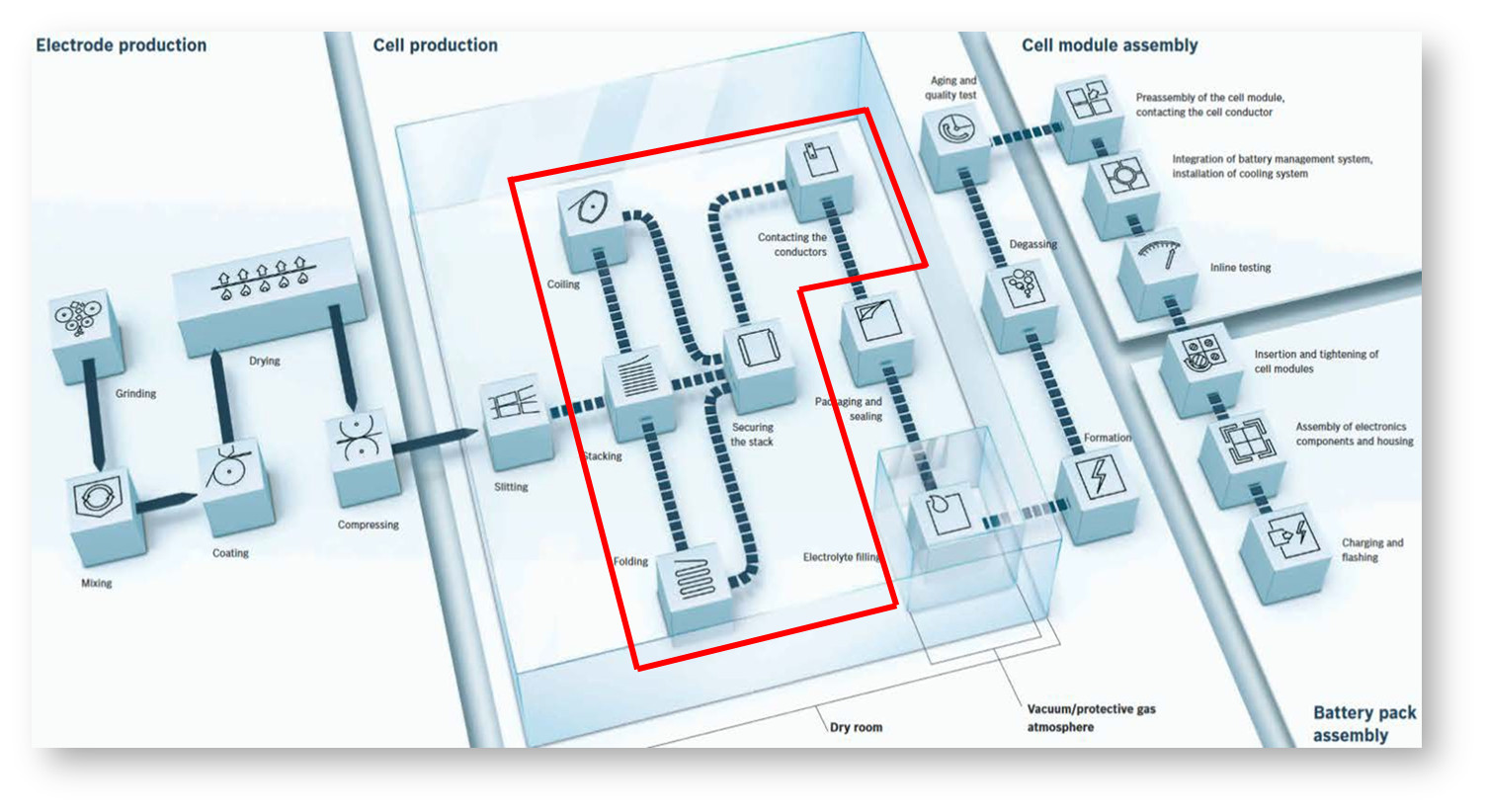

Before diving into a closer examination of the project where DWFritz and Bosch partnered, let’s briefly overview a typical cell manufacturing process. As seen in Figure 1, a typical battery cell manufacturing process includes electrode production, cell production, cell module assembly, and battery pack assembly. Within each stage there are several standard steps.

Development of a High Throughput Battery Cell Line – DWFritz and Bosch collaboration.

Electrode production includes grinding and preparation of the base materials and mixing, before going on to the coating process for the anodes and cathodes. This is followed by drying, compressing, and slitting to get to the final form factor that you want to go into the actual cell assembly.

Cell production, which is the area highlighted in red in Figure 1 and the focus of this article, involves three different processes the cell can go through for different cell geometries:

- Coiling

- Stacking

- Folding

Once those processes are completed, the cells come back together to be secured into a stable and mechanically sound product. At this point, the busbar will connect the anode and cathode conductors before the cells are packaged and sealed, formed, and degassed in a protective environment, before being tested for quality.

Following the actual cell manufacturing process, the cells move into module assembly, where multiple cells are assembled and interconnected with cooling elements or battery management electronics before final testing. Finally, modules are often assembled into larger battery packs. The modules are mechanically fastened and assembled with some electronics and controls before being charged and again tested for quality.

Battery Manufacturing Processes and Assembly Line

As a result of our partnership with Bosch, we have identified several key process improvements in developing an automated battery cell assembly line. Some of these processes are typical of any cell assembly and production line, regardless of form factors.

Throughput is one of the critical factors to maximizing the overall investment. Achieving the highest possible cycle times requires optimizing the takt times of various process modules, fully utilizing each module, and using line balancing to ensure that we fully maximize all tools.

Assembling the cathode, separator, anodes, and current collectors requires very precise assembly steps, including placement of individual layers, wrapping, or any other interconnected process. As the batteries become smaller and the energy density rises, the tolerances get correspondingly smaller, and drive a lot of the requirements of the assembly tools.

Most of the components are very delicate and must be handled very carefully, particularly the cathode, anode, and separator. Additionally, some of the bus parts are very small and very thin, so they must be carefully handled to prevent damage and maintain quality.

To connect the various components and layers together or facilitate material separation, techniques such as laser welding, thermal gluing, and precision dispensing is used. Precision busbar insertion is used to make the electrical connections between the electrical terminals (anodes and cathodes).

As mentioned earlier, materials used in battery cell production are often delicate and need to be precisely handled. Our designs incorporate precision material handling along with nests, fixtures, and pallets that assist the rapid transfer, movement, and processing of these materials within a process module, and across various modules.

Our system includes in-situ inspection, enabled by high-speed machine vision systems or lasers that perform defect detection, precise material alignment, and high-speed inspection of work-in-progress (WIP) goods. In many instances, camera or laser scans allow for machine vision software to analyze WIP parts using 2D or 3D mapping to help modules determine good vs bad parts. Only good parts are allowed to proceed to the next process step.

Identifying Key Challenges

As you can see from this brief overview, battery manufacturing is a complicated process that is not without significant challenges. But what, exactly, are those challenges? And more importantly, how do we overcome them?

Incoming Material Variability

Variability among incoming material represents a key challenge to battery manufacturing. The incoming materials come from other tools with their own variations and tolerances. The solution here is to develop a strategy to deal with those variations, as well as non-conforming materials, without affecting the throughput.

Incoming material can be defined as raw material inputs (such as a web roll) or material that is transferred across process modules. And incoming materials can have several different types of defects that are characteristic of the previous process step or is a consequence of poor production quality of raw material inputs. An effective system needs to inspect for all possible defects and develop a strategy for the disposition defective material at the time of introduction or further down the line. Additionally, we need to detect and track quality metrics that are tied back to a particular serial number for quality assessments and traceability down the road.

Tolerances for cathode, anode, and separator components, as well as housing components, are ±50µm or less. Incoming material variability can cause significant issues with achieving these final assembly tolerance requirements, which drives both tight inspection and handling requirements.

Most of cathode, anode, and separator components arrive on a big roll, requiring roll-to-roll and web handling of very fragile materials. Unwinding the rolls frequently generates static, as well, which must be managed to prevent adverse effects during the assembly process while not damaging or stretching the material.

It must be noted that systems cannot be easily designed to accommodate for a wide various of incoming material variability without impacting production costs and initial investments. It is therefore essential to ensure a robust quality assurance methodology is in place.

Throughput is one of the critical factors to maximizing the overall investment. Achieving the highest possible cycle times requires optimizing the takt times of various process modules, fully utilizing each module, and using line balancing to ensure that we fully maximize all tools.

Assembling the cathode, separator, anodes, and current collectors requires very precise assembly steps, including placement of individual layers, wrapping, or any other interconnected process. As the batteries become smaller and the energy density rises, the tolerances get correspondingly smaller, and drive a lot of the requirements of the assembly tools.

Most of the components are very delicate and must be handled very carefully, particularly the cathode, anode, and separator. Additionally, some of the bus parts are very small and very thin, so they must be carefully handled to prevent damage and maintain quality.

To connect the various components and layers together or facilitate material separation, techniques such as laser welding, thermal gluing, and precision dispensing is used. Precision busbar insertion is used to make the electrical connections between the electrical terminals (anodes and cathodes).

As mentioned earlier, materials used in battery cell production are often delicate and need to be precisely handled. Our designs incorporate precision material handling along with nests, fixtures, and pallets that assist the rapid transfer, movement, and processing of these materials within a process module, and across various modules.

Our system includes in-situ inspection, enabled by high-speed machine vision systems or lasers that perform defect detection, precise material alignment, and high-speed inspection of work-in-progress (WIP) goods. In many instances, camera or laser scans allow for machine vision software to analyze WIP parts using 2D or 3D mapping to help modules determine good vs bad parts. Only good parts are allowed to proceed to the next process step.

Precision Assembly Tolerances

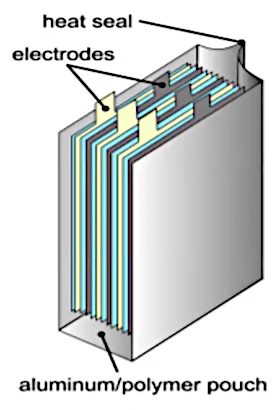

As previously mentioned, tolerances for battery cell assembly tend to be very tight, with typical cell assembly and alignment tolerances ranging from ±20 to 50µm. Figure 2 illustrates a pouch-type assembly. The alignment between the electrodes, the mechanical housing surrounding it, and the interconnection tolerances can be very tight.

The challenges to achieving these precision assembly tolerances include the previously mentioned material variability, the stack-up and housing tolerance issues among the cathode, anode, and separator components, and, of course, the overall throughput speed required. Maintaining the high level of precision while processing components at increasingly high speed is particularly critical as the overall throughput requirements directly drive the system’s ROI.

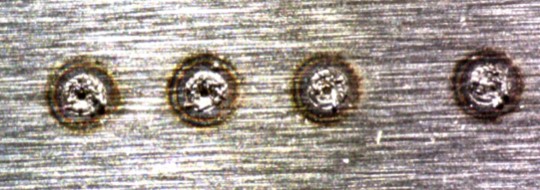

Electrical Interconnects

As reliability is critical to both safety and performance of the final cell, electrical interconnects must meet a high-quality standard and present significant challenges. Most of the products include multiple layers, such as a stacked layer or coil, that need to be connected. Generally, these connections are made with a busbar and laser welding, which requires accurately locating the busbar and preparing the material for assembly. For example, if a busbar is coming on a roll, it needs to be straightened and cut. Other times, you may need to insert 50μm-thick substrate onto the cell assembly.

We also frequently must deal with a variety of materials depending on different product configurations and product types. These materials can vary in thickness, material type, and differing mass, but ultimately, whatever the material or configuration, we must ensure good weld quality.

Speed and Throughput

With the growth in battery demand continuing to escalate, the need for higher throughput production has never been higher. Companies continue opening new factories and they are looking for faster equipment – and more of it – to meet the spike in demand. Simply put the challenge here is hitting target cycle time while maintaining both accuracy and repeatability. Customers not only desire higher throughput, but also better ROI and smaller footprint.

While production speeds continue to accelerate, batteries are becoming increasingly smaller with higher energy densities and much tighter tolerances. These demands mean that our cell manufacturing systems are working at the micron level and with typical GRR values of <15%. These requirements present challenges with material handling, inspection, and metrology. Achieving these demanding requirements while maintaining accuracy demands new and innovative approaches to system optimization using controls, vibration, active feedback, and other tools, not to mention business partners, such as DWFritz and Bosch-Rexroth, overcoming such challenges.

Flexibility and Scalability

In addition to speed and throughput, flexibility is another big factor in a systems ROI. Any system must be flexible and scalable to meet the requirements of this rapidly evolving market. Cell assembly tools must adapt to changes as new processes develop and throughput requirements change.

Automation systems also must have the capability to rapidly reconfigure the production line for different form factors. From prismatic or cylindrical batteries to pouch and button cells, we design production lines to support different form factors of a cell with minimal changeover time.

Another part of maximizing a tools flexibility is allowing seamless communication of system data to anywhere in the world. Modern manufacturing companies employ a global approach, with production facilities spread across countries and even continents. To maximize production efficiency and serviceability, system must be integrated with an ability to monitor operation of multiple production lines in different geographies.

Manufacturing battery cells is a complex, demanding process with significant challenges. Designing and building a flexible, high-speed system that overcomes these challenges while producing a high-quality product requires a high-level of technical expertise, innovation, and experience. In part 2 of our blog, we will look at how DWFritz and Bosch-Rexroth partnered to develop a comprehensive system to meet our client’s needs.