Our Blog

Get the latest insights and knowledge leadership from our inspection and precision automation experts.

The Journey of a Product with Contract Manufacturing

The journey of a product begins with a concept, an idea that has been vetted by customers. For products in the physical space, this idea then becomes a set of engineering drawings. At some point during its life-cycle, these drawings need to come to life. This can...

Criteria to Consider When Evaluating a Contract Manufacturer’s Competency, Part 3

Having delved into the intricacies of contract manufacturing in Part 1 and Part 2, join us in Part 3 where we'll further explore the nuances and final considerations essential for making an informed decision. Don't miss this deep dive into the culmination of our...

Criteria to Consider When Evaluating a Contract Manufacturer’s Competency, Part 1

Build-to-Print (BTP), also known as copy exact, build to reference, or volume manufacturing, is a specialized manufacturing approach wherein a company produces components, assemblies, or products strictly based on client-provided blueprints and specifications. This...

Criteria to Consider When Evaluating a Contract Manufacturer’s Competency, Part 2

Welcome to the second installment of our deep dive into Build-to-Print (BTP) with DWFritz Automation. As we further explore the intricacies of BTP, it's crucial to have a well-rounded understanding. If you haven't had a chance to review Part 1 of our series, we highly...

Mastering Value – How Value Added Value Engineering Can Drive Business Success, Part 2

VA/VE's principles of cost efficiency and functional optimization are crucial across sectors like automotive, healthcare, manufacturing, and semiconductors. Its adaptability and emphasis on value make it sought-after strategy among industry leaders in these...

Mastering Value – How Value Added Value Engineering Can Drive Business Success, Part 1

In today's rapidly evolving business landscape, understanding the core principles that drive product quality and profitability is paramount. Among these principles, the concepts of Value Added Value Engineering - (VA/VE) stand out as powerful tools that companies can...

Five Keys to Executing a Precision Automation Project

Automating advanced manufacturing systems is a complex process that requires careful planning and execution. The right time to automate will depend on several factors, including the nature of the products being manufactured, the size and complexity of the factory, and...

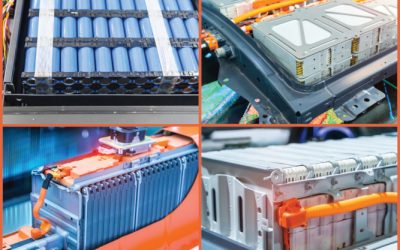

Fully Automated Battery Manufacturing, Part 2

Manufacturing battery cells is a complex, demanding process with significant challenges. In part 1 of our series, we highlighted the key challenges in developing a fully automated battery manufacturing line. Now, we look at how DWFritz and Bosch-Rexroth partnered to...

Fully Automated Battery Manufacturing, Part 1

With more than 20 million electric vehicles expected to hit the market by 2030, the automotive industry alone is significantly increasing demand for new products and technologies in the battery cell market. This rapid market expansion will present manufacturers with...