In today’s rapidly evolving business landscape, understanding the core principles that drive product quality and profitability is paramount. Among these principles, the concepts of Value Added Value Engineering – (VA/VE) stand out as powerful tools that companies can leverage to gain a competitive edge. And VA/VE can be a game-changer. But how do they influence the way businesses design, produce, and sell their products?

In this article we will delve into this methodology, exploring its essence, impact, and how businesses, big and small, can integrate them for improved outcomes. Dive with us into the compelling intricacies of value and its pivotal role in modern business.

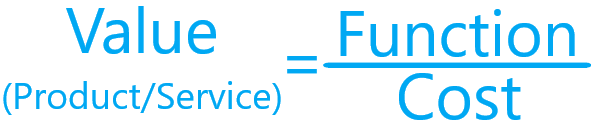

At the gross level, value can be defined by a measure of a product’s worth that is determined by its function relative to its cost. Enhancing value can be achieved by either amplifying its function, reducing associated costs, or a combination of both.

Defining Value

In value added and value engineering, the term ‘value’ often finds its foundation in the concept of use value—defined by a product’s attributes, its application, and purpose. Both value added and value engineering hinge on this understanding, shaping offerings to align with and exceed customer expectations. Enhancing value directly elevates customer satisfaction and increases loyalty.

VA/VE Unraveled: Understanding Value Added & Engineering

Broadly speaking, VA/VE is a manufacturing and engineering methodology that influences product design and it’s manufacturing. If done right, it can also improve upon process engineering. Originally, VA/VE emerged as a strategy during periods of national shortages where halting the manufacturing of crucial products wasn’t an option. However, after being integrated into manufacturing, engineers observed that VA/VE not only preserved product functionality but also resulted in cost savings. In certain instances, it even enhanced product performance. Its relevance was once again highlighted during the Covid-19 pandemic when supply chain disruptions exposed vulnerabilities across sectors, underscoring VA/VE’s effectiveness in addressing such challenges.

VA/VE aims to optimize a product or even a process by balancing cost and function. Through evaluating each functional attribute and its component cost-effectiveness, specialists collaborate to suggest alternative materials, designs, and techniques, ultimately aiming to reduce costs and enhancing functionality.

Exploring the Core of Value Engineering

At the heart of VA/VE, value engineering is a method strategically employed prior to the manufacturing phase. Industry experts prioritize the preservation of a product’s inherent functions during this process, ensuring alignment with customer expectations. In the realm of value engineering, professionals contemplate alternative materials, design methodologies, manufacturing approaches, coding, DFM, DFA, component substitutions, and shipping logistics. Such depth in approach underscores the commitment to not only optimizing both cost and product functionality, but also manufacturability.

Building upon value engineering principles, its application can become a catalyst for product evolution. Teams merge diverse knowledge, ensuring the best decisions, from product design to material selection to manufacturing to shipment logistics. The outcome? Products that can be delivered to target markets at forecasted demand volume at the most optimal cost.

The impact of this methodology is most felt with the development of new products, where the products are designed with manufacturability in mind. This holistic approach is often used with existing products to optimize the cost value function to extract the best value.

DFM (Design for Manufacturability) ensures products are designed for cost-effective manufacturing. DFA (Design for Assembly) optimizes design for efficient assembly, reducing costs and time.

Six Steps to Mastering Value Engineering

- Gather Information: Evaluating a product’s lifecycle involves examining stages from design to manufacturing to sales and distribution.

- Think Creatively: Success in VE often involves embracing risks-be it through novel methods or reimagining established ones. It invites creative explorations: from material substitutions and design alterations to eliminating superfluous features or resequencing the manufacturing stages.

- Evaluate Ideas: Determine which concepts merit inclusion in the product, weighing each idea’s advantages and disadvantages.

- Develop and Analyze: After ranking, the top ideas undergo in-depth analysis. This involves creating model plans, detailing proposed changes and implications, revising financial estimates, timeline analysis, theory-of-constraints, resource analysis, updating design visualizations, and evaluating change viability.

- Present Discoveries: After finalizing plans and presentations, showcase the top ideas to senior leadership. Typically, multiple suggestions are tabled, accompanied by an updated timeline, financial forecasts, visualizations, and relevant references.

- Implementation and Monitoring: Once changes are implemented and production restarts, its crucial to monitor closely, ensuring the updated procedures function optimally.

We’ve delved into Value Engineering and the essence of VAVE. In Part 2, we’ll unpack ‘Value Added’ and spotlight DWFritz’s unique approach to VAVE. Stay tuned for deeper insights in our next segment.