Systèmes d’automatisation engineer-to-Order

Que vous ayez besoin d’une ligne de production avancée entièrement automatisée ou d’un module de processus pour un défi de fabrication complexe, nous sommes votre partenaire en matière d’automatisation.

Prêt à commencer ?

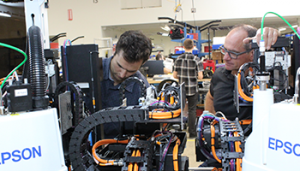

Nous sommes The Precision Automation Experts™

L’automatisation n’est pas la même partout. L’automatisation de précision exige un autre niveau d’expertise. C’est ce point qui nous définit. Nous sommes spécialisés dans l’automatisation de la fabrication end-to-end, l’intégration complète d’usine, la construction de modules à grande vitesse et haute précision (de l’ordre du micron), l’automatisation de l’assemblage et des processus pour la fabrication avancée dans les applications HVLM et LVHM. Nos équipes d’ingénierie et de gestion de projet de classe mondiale sont reconnues dans le secteur pour fournir les solutions les plus innovantes, incorporant des logiciels personnalisés, des architectures flexibles conçues par DWFritz, les meilleurs capteurs de leur catégorie, des systèmes de vision industrielle, des robots et un contrôle de mouvement & de manutention de précision.

Nos capacités

Assemblage, test et automatisation des processus

Nous sommes spécialisés dans l’automatisation de l’assemblage et des tests à grande vitesse et de précision pour diverses applications de fabrication dans de nombreux marchés verticaux, tels que l’électronique grand public, les dispositifs médicaux, l’e-mobilité, l’automobile, le stockage d’énergie, la logistique et le transport.

Nous sommes reconnus dans le secteur pour fournir les solutions les plus innovantes, intégrant des éléments de processus complexes, tels que le contrôle de mouvement de précision, la manutention, la distribution, le soudage et la détection de force. Nos solutions se caractérisent par leur précision et leur rapidité pour permettre un débit de production élevé et une qualité de produit supérieure.

Appareils AR/VR

Nous excellons dans le traitement, l’assemblage et le test de dispositifs AR/VR complexes, tant pour les applications grand public que militaires. Grâce aux mouvements précis des hexapodes, des robots et des portiques, associés à nos dispositifs de fixation et à nos algorithmes logiciels conçus sur mesure, nous sommes en mesure d’articuler des pièces délicates avec des tolérances de l’ordre du micron.

Cellules de batterie

Nous possédons l’expertise nécessaire pour fabriquer des cellules de batterie avec des composants chimiques et des facteurs de forme variés pour des applications dans des secteurs tels que l’électronique grand public, les véhicules électriques ou le stockage sur réseau d’énergie.

Modules ou packs de batterie

Notre expertise en matière d’assemblage, d’inspection et de test de modules ou de packs de batteries a permis à un grand nombre de nos clients de différents secteurs d’activité de commercialiser des produits et des solutions innovants. Nous sommes spécialisés dans l’intégration et l’assemblage à grande vitesse de cellules grâce à notre expertise avancée en matière de systèmes de vision, d’IA, de collage, de distribution, d’installation de connecteurs & de câbles, de tests en bout de ligne et de soudage au laser & par ultrasons.

Architecture de conception flexible

Nos lignes d’automatisation end-to-end utilisent notre architecture de conception flexible brevetée, qui nous permet d’exploiter et d’utiliser des plateformes unifiées sur l’ensemble de la ligne, améliorant ainsi la fiabilité, la disponibilité et la facilité d’entretien de nos lignes entièrement automatisées.

Dispositifs médicaux et implants

Nous excellons dans la conception et le déploiement de lignes de production et de systèmes qui aident à produire ou à tester des implants et des dispositifs médicaux, y compris de petits implants de la taille d’un grain de riz et des bobines emboliques qui aident à prévenir les anévrismes. Nous aidons nos clients à tester leurs valves cardiaques et à fabriquer des kits de test Covid rapide. Nos produits ZeroTouch® peuvent inspecter des implants spéculaires, tels que des raccords de genou, des articulations d’épaule ou des articulations de hanche, en utilisant des techniques à grande vitesse et sans contact.

Appareils mobiles

Notre équipe dispose d’une grande expertise pour permettre la fabrication en grand volume d’appareils mobiles, tels que les téléphones cellulaires, les tablettes ou les accessoires pour le marché de l’électronique grand public. Nos capacités vont de la construction de lignes de production complètes au développement de modules dans une large gamme de produits.

Ingénierie de précision

Nos systèmes d’automatisation des processus et de l’assemblage utilisent le mouvement coordonné précis des matériaux sur plusieurs degrés de liberté, guidé par des sous-systèmes de vision et de capteurs, et alimenté par un logiciel personnalisé. Nos solutions d’automatisation font appel à un vaste éventail de compétences techniques et d’ingénierie de précision dans plusieurs domaines clés.

Nous excellons dans la conception de montages, permettant de maintenir en toute sécurité des pièces faites de matériaux et de tailles différents sans les endommager. Notre expertise en matière de manutention de précision et de contrôle du mouvement facilite les mouvements hautement répétables des pièces, ce qui permet un traitement et une inspection des pièces extrêmement rapides.

Distribuer

Nous excellons dans les applications de distribution de précision. Nos systèmes de vision localisent et alignent de multiples composants avec une tolérance de 5 μm, fournissant un retour de vision afin d’améliorer la précision et la répétabilité. Nos systèmes de distribution de colle à têtes multiples appliquent 0,034 microlitres de colle. Nos systèmes de vision et confocaux effectuent ensuite une détection du volume in situ et des mesures de l’écart final pour confirmer la qualité de la pièce.

Gravure

Nous sommes spécialisés dans l’électro-traitement de dispositifs d’implants médicaux. Ce traitement peut servir à anodiser les surfaces intérieures pour le codage couleur, à préparer les surfaces pour le revêtement final ou bien à améliorer la porosité pour le collage.

Retraits et fixations

Nous avons conçu et construit des systèmes de retrait et de fixation qui découpent et fixent des buses avec une précision de 10 μm sur des plaquettes de semi-conducteurs à l’aide de plusieurs points adhésifs de 150μm avec une précision de 20 μm. Nos systèmes sont capables de couper et d’insérer rapidement des fils de 0,12 mm dans des trous de 0,25 mm de diamètre. Ces systèmes flexibles utilisent des technologies de vision pour localiser les composants, des pinces multifonctionnelles pour s’interfacer avec des cellules de charge personnalisées afin de transférer les composants entre les processus, ainsi que des logiciels de contrôle personnalisés basés sur des recettes.

Conception de montages

Pour déplacer avec précision des matériaux et des pièces sur des lignes et des systèmes de production, nous concevons des montages sur mesure qui permettent aux pièces d’être manipulées en toute sécurité et facilement par des EOAT montés sur des robots ou des systèmes de portique, afin de garantir que les pièces sont manipulées délicatement sans être abîmées ni endommagées.

Détection de force

Nous utilisons des capteurs de force à trois axes pour guider nos robots avancés exerçant une pression lors de collages ou de retraits de couches de masquage. Nous utilisons également des capteurs de couple pour actionner les vis. Ces technologies aident à la manipulation de matériaux délicats.

Pesage de composants en cours de fabrication

Nos systèmes d’automatisation comprennent parfois des stations de pesage en nid mort où les produits finaux sont pesés pour répondre aux normes prédéfinies du client. En transmettant des données de poids précises à travers des réseaux à grande vitesse, nos systèmes assurent une production maximale et une qualité élevée.

Stratification

Nos systèmes de stratification utilisent de multiples sous-systèmes, notamment des applicateurs d’étiquettes, des nids de stratification, des rouleaux de stratification, des cassettes d’entrée & sortie, des actionneurs de prise & de mise en place et des systèmes de traitement des rejets. Nos systèmes ont été déployés dans des applications de semi-conducteurs et de mise en œuvre de technologie à sortance.

Traitement laser

Nous utilisons le traitement laser dans de nombreuses applications, notamment la gravure, le marquage et l’ablation. Nos systèmes d’ablation au laser éliminent avec précision les enduits de surface de zones spécifiques des matériaux,. Nos systèmes de gravure, quant à eux, intègrent une robotique et une vision artificielle avancées pour orienter, graver au laser et assembler les composants.

Manutention des matériaux et contrôle du mouvement

Nous croyons à l’adage « Le contrôle du mouvement fait avancer les techniques de manipulation ». Notre expertise dans le domaine de la manipulation de précision est inégalée, qu’il s’agisse de mouvements alimentés par des convoyeurs, des élévateurs, des systèmes multi-axes, des étages ou des fluides (air ou liquide). Nous pouvons obtenir un « positionnement infini » en utilisant un actionnement électrique permettant un contrôle complet et précis. En plus de contrôler la vitesse (accélération, décélération et vélocité) avec une précision de l’ordre du micron, nous nous assurons également que le matériel est manipulé en toute sécurité sans endommager les pièces.

Applications de micro-précision

Nous concevons et construisons régulièrement des systèmes d’automatisation équipés des systèmes de vision et de mesure laser capables de respecter des tolérances dimensionnelles de 50 μm avec une répétabilité submicronique. Les solutions de distribution de précision automatisées sont l’une de nos spécialités. Nous sommes capables d’atteindre des vitesses de distribution de 150 millisecondes par placement avec une répétabilité de 20 μm.

Systèmes multi-axes

Nos ingénieurs conçoivent et fabriquent des systèmes d’automatisation complexes avec des bras multi-axes et un retour de mouvement, augmentant les capacités de flexibilité et de répétabilité, pour mesurer des géométries complexes telles que des alésages, des contre-dépouilles, des sphères, des formes organiques et des chanfreins.

Traitement de surface au plasma

À l’aide d’un portique de précision à vis à billes multi-axes, de systèmes de dépose à une ou plusieurs têtes, du séchage UV et de l’ablation laser, nos systèmes déposent avec précision des nano-litres de matériau sous forme de points, de lignes ou de formes irrégulières sur les bords des connecteurs, sans déborder.

Sertissage

Nos systèmes d’assemblage à grande vitesse orientent, assemblent, sertissent et inspectent les composants à une vitesse de 1,25 seconde par assemblage. À l’aide d’un logiciel de contrôle personnalisé, les processus automatisés sont pilotés par des recettes basées sur les exigences du client et du produit, et trient et regroupent les produits finis sur des lignes d’emballage et des bacs de rejet.

Vision et retour d'information des capteurs

Nous utilisons des systèmes de retour d’information par vision artificielle pour orienter les composants avec précision sur des distances et des angles inférieurs à une dizaine de microns ou de microradians. Des émetteurs et des récepteurs à faisceau direct permettent de s’assurer que les mandrins sont dégagés avant de charger de nouvelles pièces. Des lasers d’identification confirment que les pièces restent stables sur les convoyeurs. Enfin, des lecteurs de codes-barres scannent les identifiants des pièces pour une personnalisation des processus basée sur les recettes.

Soudage par ultrasons

Nous intégrons des palpeurs de précision capables d’une résolution de 12,7 μm dans les têtes de soudage par ultrasons pour échantillonner des points le long des joints à souder avant de procéder au soudage. Nos systèmes cartographient avec précision les affleurement de soudures sur des matériaux avec des variations d’épaisseur non uniformes, en ajustant et en calibrant automatiquement la hauteur selon les besoins pour garantir l’uniformité.

Manipulation de plaquettes

Nos systèmes flexibles de manipulation des plaquettes détectent et mesurent les tranchées dans les plaquettes de silicium avec une précision inférieure au 1μm, tandis que nos systèmes de laminage produisent des assemblages complets à un rythme de 9 secondes par laminage.

Manutention de bandes

Nos systèmes de manutention de bandes conçus sur mesure permettent non seulement de manipuler ou transporter une grande variété de matériaux de batteries contenant différents composants chimiques, mais aussi de les traiter à grande vitesse avec une précision de l’ordre du micron.

Inspection 2D/3D à grande vitesse

Nous sommes experts en métrologie et en inspection à grande vitesse, sans contact et basée sur la vision. Nos systèmes d’inspection automatisés, personnalisés et à grande vitesse identifient et classent les défauts de l’ordre du micron et les défauts de surface sur une large gamme de matériaux, y compris les matériaux transparents et translucides.

Nous concevons et développons des solutions qui permettent d’optimiser les processus en amont, d’améliorer la qualité des produits et d’éviter les rappels coûteux de dispositifs avant que les produits n’atteignent les consommateurs.

Alésages et filetages

Nos systèmes et technologies permettent de mesurer les alésages & les profils de filetage au niveau du micron.

Classer et mettre en bac

Non seulement nous sommes capables de trier et de mettre en bac les bons et les mauvais produits, mais nos systèmes sont également dotés d’un logiciel d’apprentissage profond et d’une vision artificielle avancée leur permettant de classer les défauts pour trier les produits en fonction du type de défaut.

Vérification des composants

Grâce à des systèmes multicapteurs et à un logiciel d’apprentissage automatique piloté par l’IA, nos solutions à grande vitesse inspectent et vérifient tous les aspects d’un composant, y compris les dimensions critiques, les défauts de surface, les déformations, les gouges, les bosses et les rayures. Notre logiciel peut comparer les images scannées avec des dessins CAO pour garantir la conformité aux tolérances et la qualité des pièces.

Défauts esthétiques

Les défauts esthétiques, tels que les rayures, les bosses, les creux et les malformations de l’ordre du micron, sont détectés à grande vitesse par des capteurs et des systèmes basés sur la vision dans nos modules. Les images et les entrées du capteur sont analysées par notre logiciel personnalisé alimenté par l’IA.

Inspection des pièces usinées

Nos systèmes ZeroTouch® reposent sur un matériel informatique et une architecture logicielle qui leur permettent de mesurer les dimensions critiques de pièces usinées à très grande vitesse en utilisant des techniques sans contact. Nos systèmes d’automatisation personnalisés, qu’ils soient en ligne, en bord de ligne ou hors ligne, emploient des techniques sans contact éprouvées et reposent sur nos connaissances de l’ingénierie de précision pour mesurer et inspecter des pièces usinées.

Inspection d'étiquetages et d'emballages

Nos systèmes effectuent l’inspection et la classification des défauts pour les emballages et les étiquettes de dispositifs médicaux de classe 3 sur différents types de matériaux, tels que le Poly-Poly et le Poly-Tyvek. Nous inspectons des emballages se déplaçant à 250 millimètres par seconde avec des caméras de vision artificielle d’une résolution de 11 pixels², un éclairage stroboscopique personnalisé et un logiciel d’apprentissage profond pour capturer des défauts de 50 μm de diamètre.

Nous concevons et construisons des systèmes ultra-précis avec une combinaison de vision industrielle haute performance, de différents robots et de logiciels personnalisés sophistiqués pour imprimer, placer et inspecter les étiquettes avec une précision supérieure à 70 μm toutes les 7,5 secondes.

Finition de surface

Nos systèmes sont capables de mesurer la rugosité et de profiler des micro ou nanostructures sur une multitude de finitions de surface.

L’histoire d’un succès

Depuis près de 50 ans, DWFritz Automation est le partenaire de confiance de nombreuses entreprises du Fortune 500, leur fournissant des solutions d’inspection, de métrologie et d’automatisation de précision. Nous avons bâti notre réputation en collaborant à la conception, au développement et à la construction de solutions clés en main innovantes.

L’entreprise a livré et installé plus de 2 000 systèmes à travers le monde. Nous sommes fiers de nos solutions et de notre assistance mondiale, et sommes impatients de vous aider à atteindre vos objectifs de fabrication.

Notre processus collaboratif

Notre objectif est de fournir un service exemplaire à nos clients en collaborant continuellement avec leurs équipes d’ingénierie, de gestion de projet et de production pendant toutes les phases du projet, y compris la conception, la production, les essais, l’IAT, le FAT et le SAT, afin de nous assurer que tous les objectifs du client ont été atteints.

Nos capacités

Nos capacités fondamentales en ingénierie de précision, en automatisation de l’assemblage et en inspection et métrologie à grande vitesse et sans contact nous permettent d’aider nos clients à maximiser leur retour sur investissement et à améliorer considérablement leur efficacité opérationnelle. Nos systèmes et solutions sont capables d’une précision submicronique pour répondre à vos normes GRR exigeantes.

Nos collaborateurs

Notre vaste expertise provient non seulement de lourds investissements dans la R&D, mais aussi de l’étendue des connaissances que nos collaborateurs apportent grâce à des décennies d’expérience dans divers secteurs industriels.

Ressources

Téléchargez des études de cas, des livres blancs ou des fiches de solutions pour en savoir plus sur nos systèmes d’automatisation de précision.

Assemblage de seringues à haute vitesse

Un outil automatisé à grande vitesse pour orienter, lubrifier, assembler et finaliser des seringues médicales sur une ligne de conditionnement.

Tissage de fil robotique

Un système automatisé pour tisser des fils en alliage spécial autour de disques métalliques en fonte fournis par le client.

Inspection visuelle de précision

Un système de vision pour effectuer une inspection à 100 % de motifs adhésifs structurels et du placement de matrices.