-

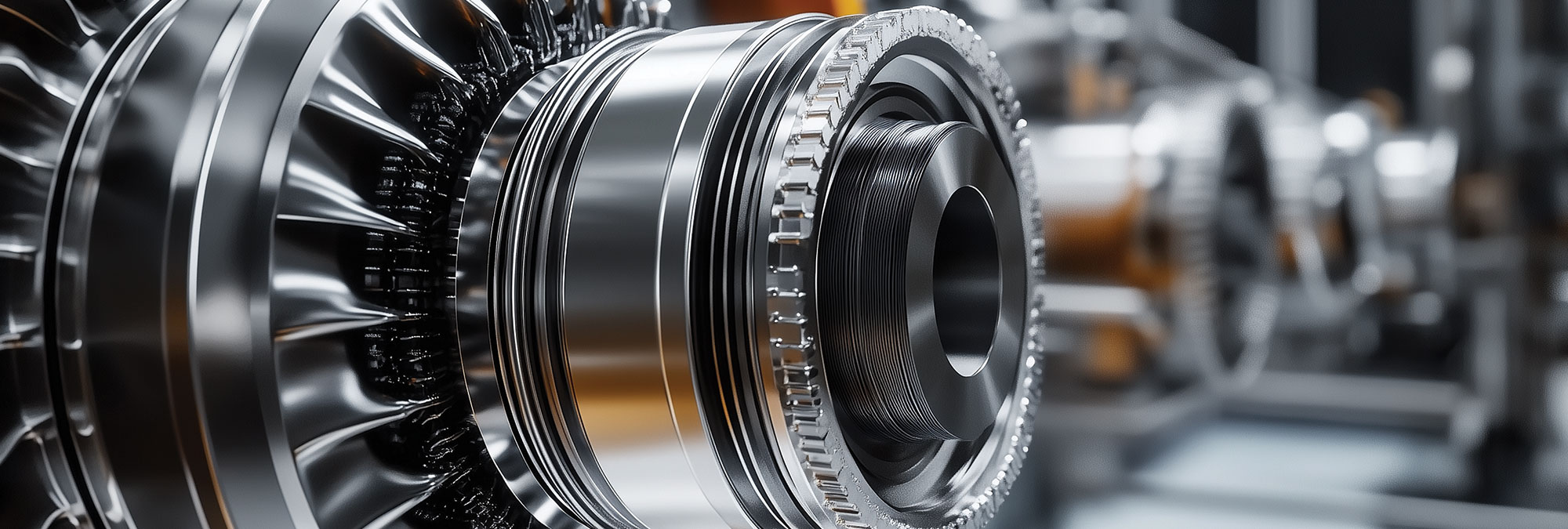

How Value Added Value Engineering Can Drive Business Success

In today’s rapidly evolving business landscape, understanding the core principles that drive product quality and profitability is paramount. Among these principles, the concepts of Value Added Value Engineering – (VA/VE) stand out as powerful tools that companies can leverage to gain a competitive edge. And VA/VE can be a game-changer. But how do they influence…

-

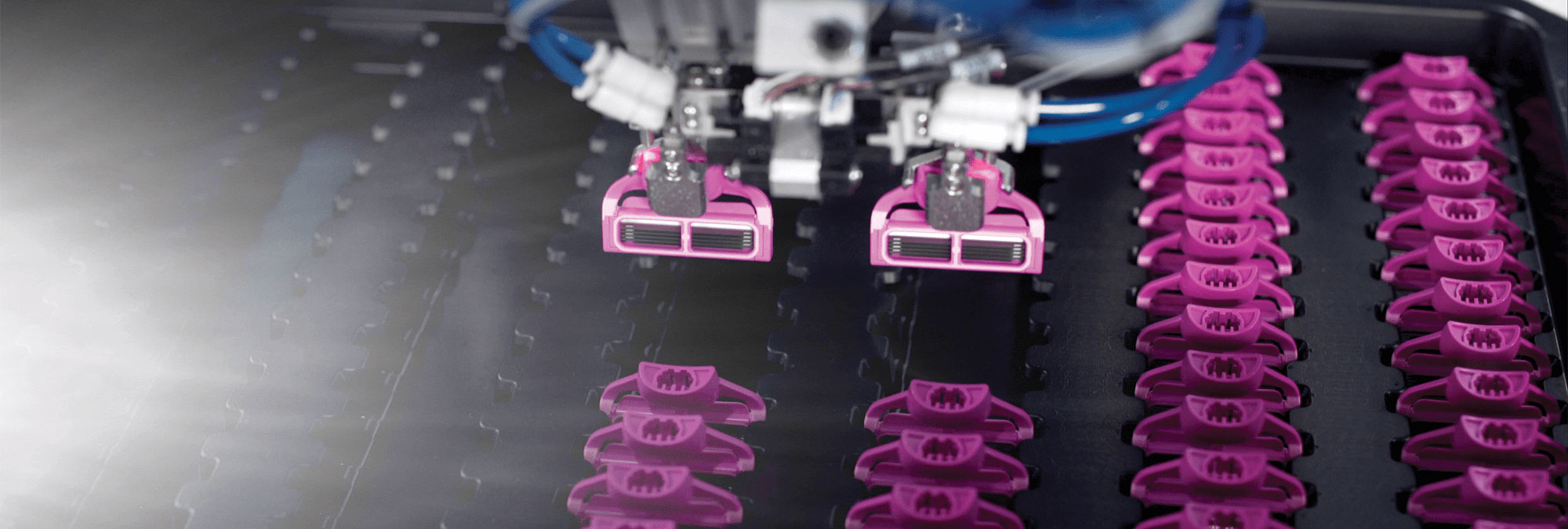

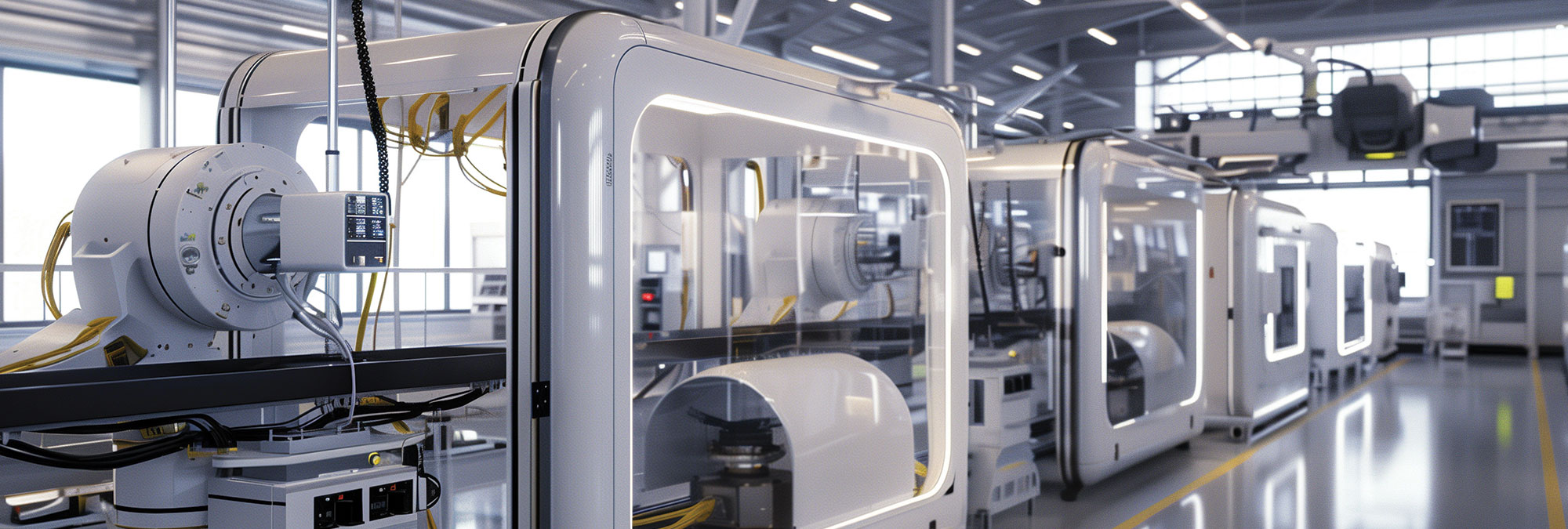

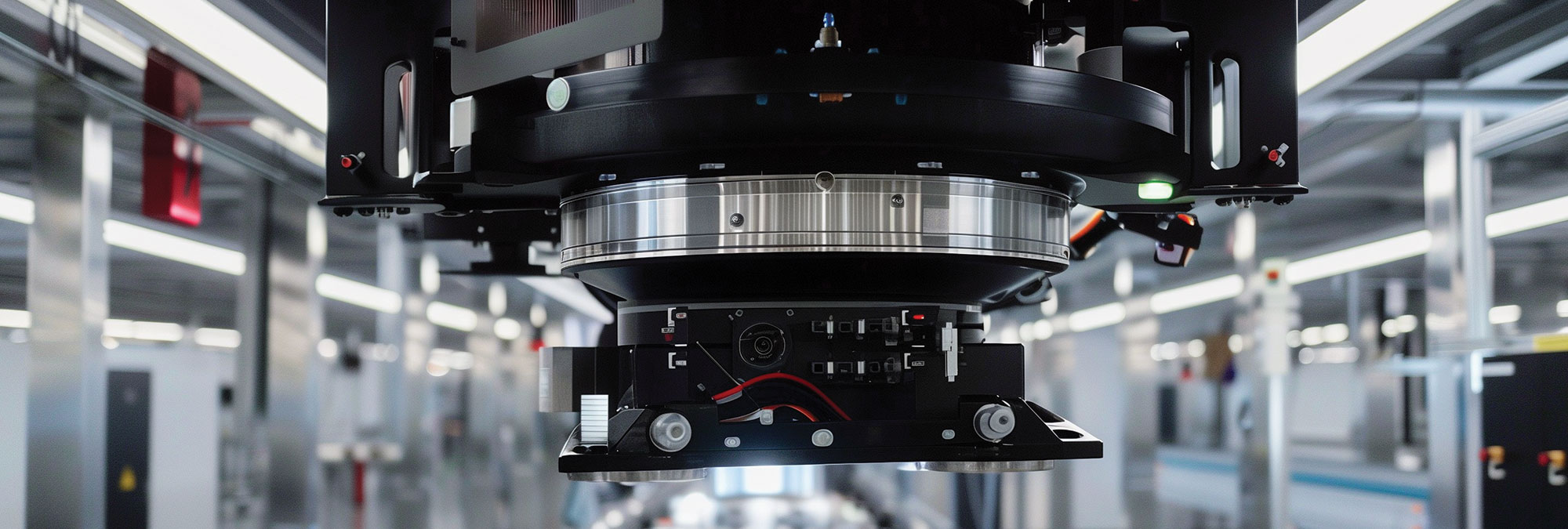

Fully Automated Battery Manufacturing

With more than 20 million electric vehicles expected to hit the market by 2030, the automotive industry alone is significantly increasing demand for new products and technologies in the battery cell market. This rapid market expansion will present manufacturers with significant challenges, but to overcome these challenges, first we need to identify the critical aspects…

-

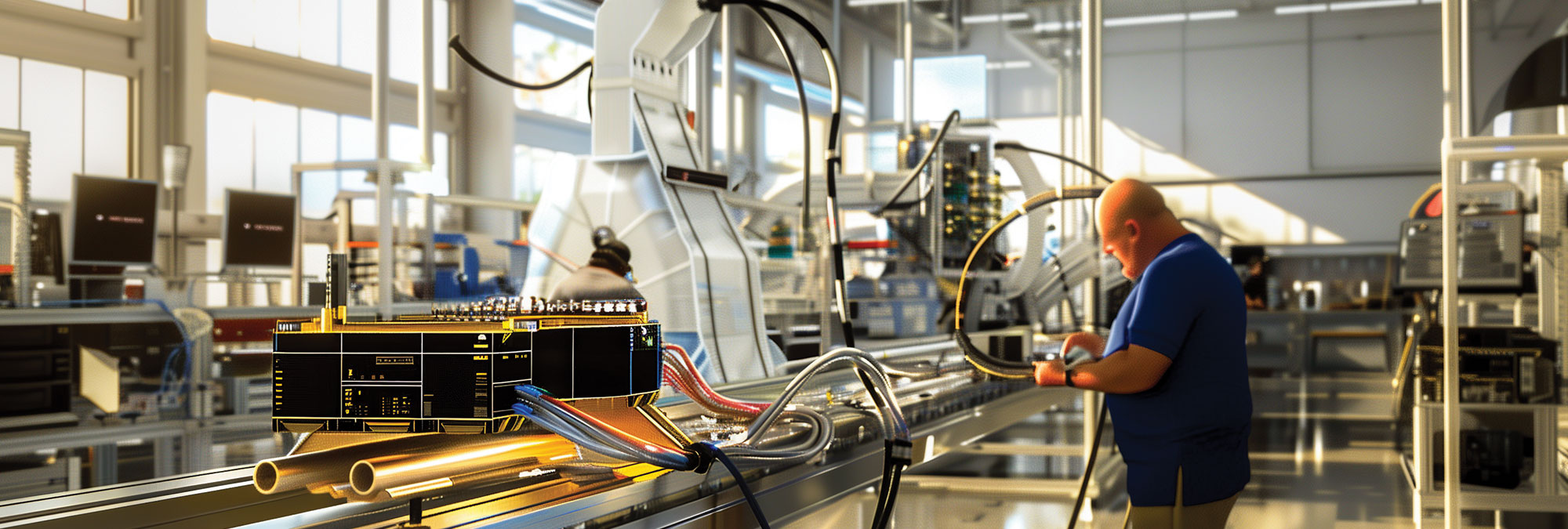

Responsive, Adaptive, Connected Manufacturing

The time has come for manufacturers, big and small, to understand and embrace the evolving production models, materials, and technologies of smart factories. Industry 4.0 is helping manufacturers increase business value by enabling a more connected, cost efficient, responsive, and quality-driven production process. Centered around a heightened emphasis on digitization and connectivity, Industry 4.0 is…

-

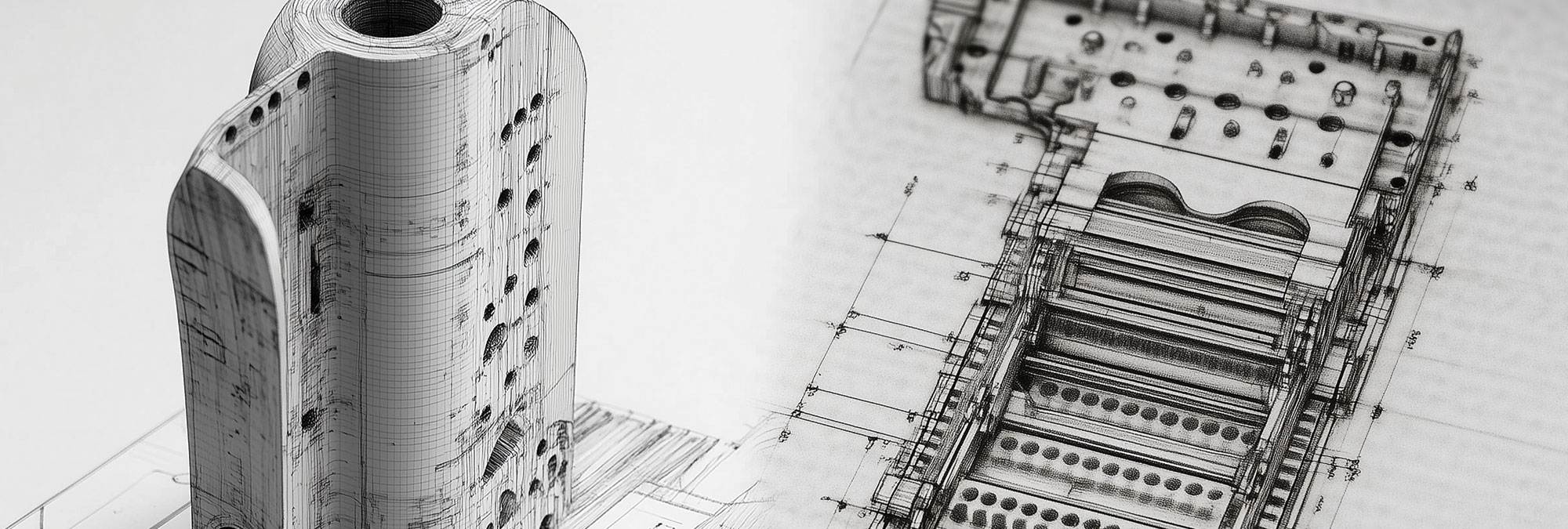

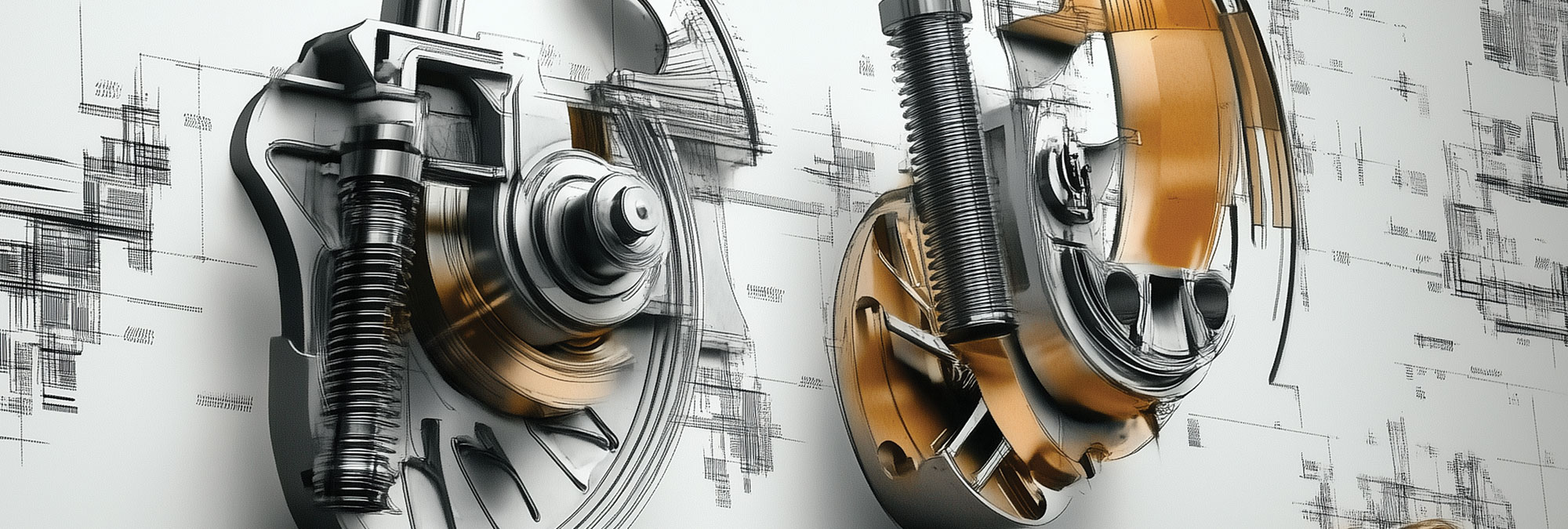

The Journey of a Product with Contract Manufacturing

The journey of a product begins with a concept, an idea that has been vetted by customers. For products in the physical space, this idea then becomes a set of engineering drawings. At some point during its life-cycle, these drawings need to come to life. This can occur in one of two ways, the customer…

-

How Transparent is Your Contract Manufacturing Relationship?

DWFritz’s Core Values consist of 1) Act With Honesty and Integrity, 2) Find a Better Way, 3) Collaborate and Share The Credit, 4) Deliver Solutions We Can Be Proud Of, and 5) Wow the Client. We take our values to heart and apply it in our day to day business activities. Our strategy is to…

-

Cost Drivers in Contract Manufacturing

Most people are familiar with the concept of Total Cost of Ownership (TCO). TCO helps articulate the cost of owning a product or system, establish the ROI, and justify the investment. TCO calculations are usually based on unit costs and, often, these do not factor in cost drivers that stem from manufacturing operations. For any…

-

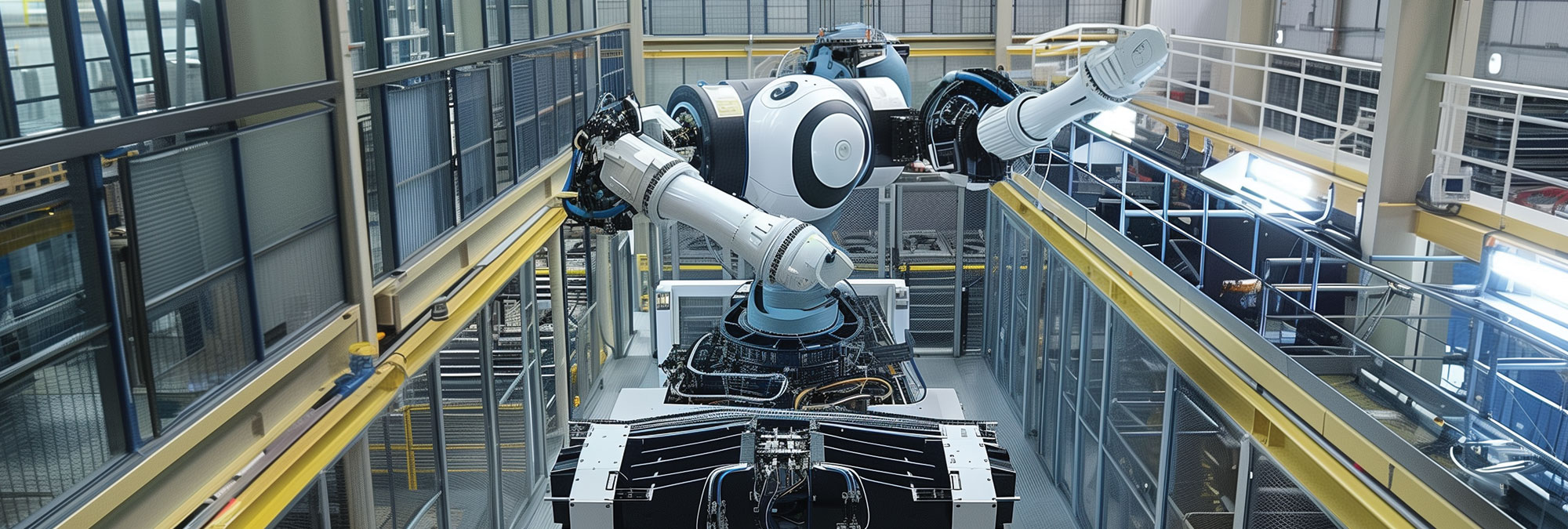

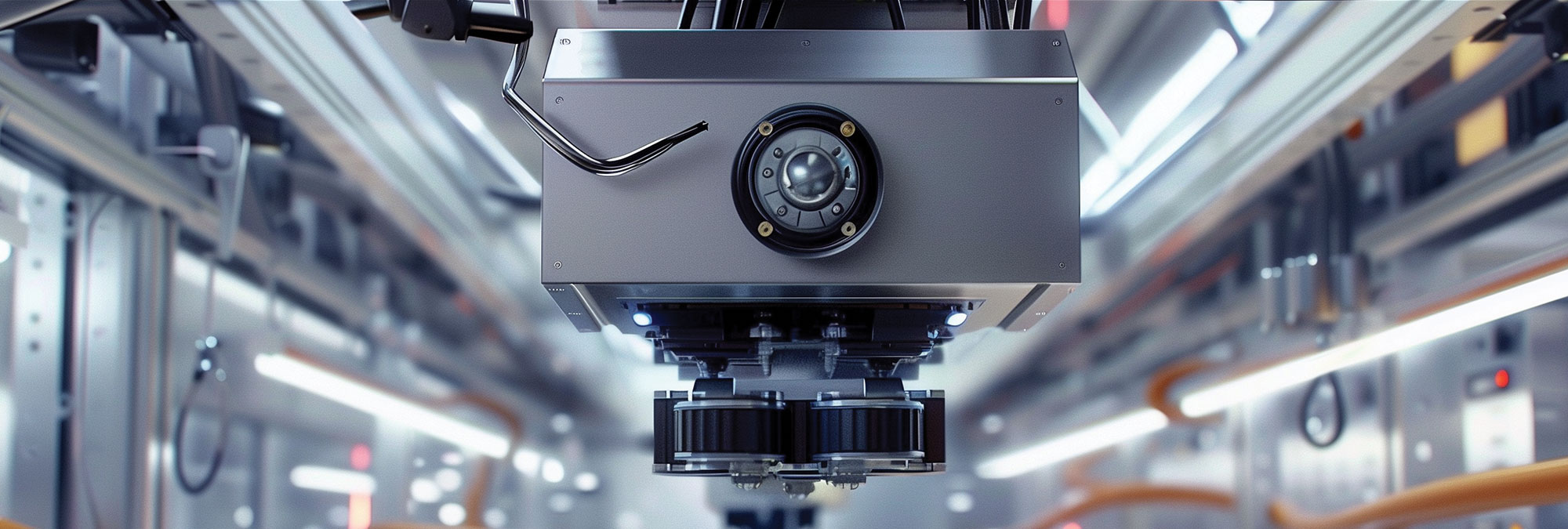

Scaling Up to a Smart Factory with Automated Assembly

Automated assembly stations provide higher productivity and product quality while lowering product cost in a fraction of the space required for conventional tooling. Staying competitive in the drive toward smart manufacturing often means fully automating assembly, packaging and inspection operations. Many manufacturers are finding that high speed, high precision assembly stations optimize production workflows while…

-

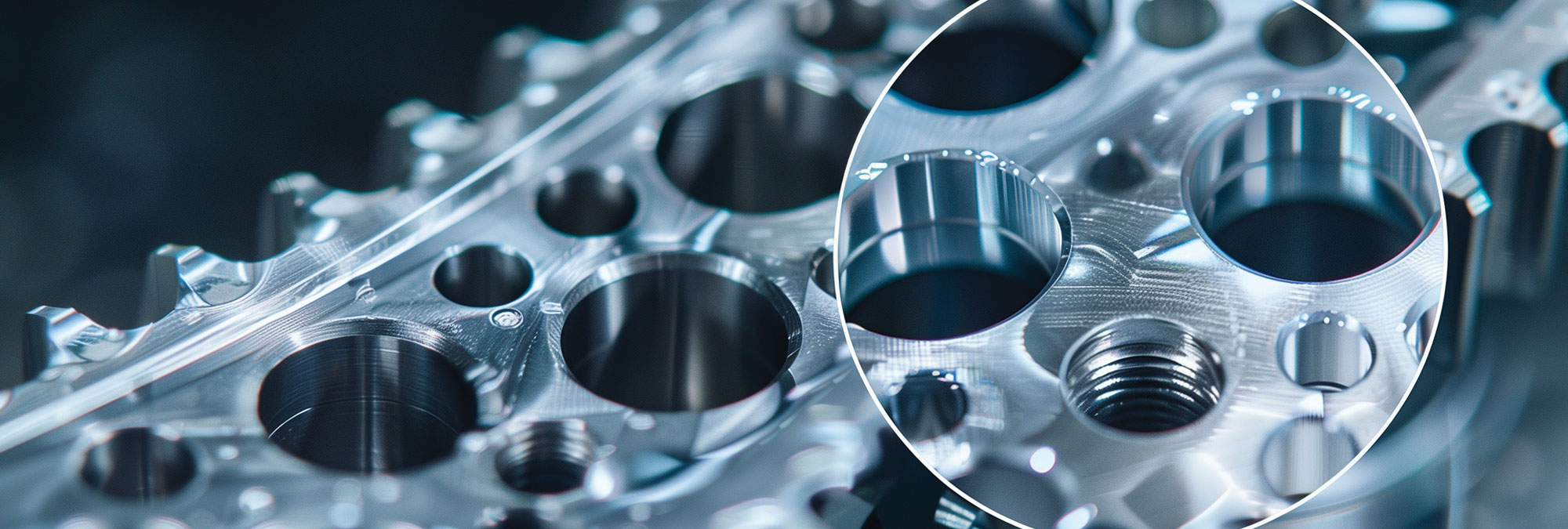

Criteria to Consider When Evaluating a Contract Manufacturer’s Competency

Contract Manufacturing (CM), also known as Build to Print (BTP), Copy Exact (CE), Build to Reference (BTR), or High Volume Manufacturing (HVM), is a specialized manufacturing approach wherein a company produces components, assemblies, or products strictly based on client-provided blueprints and specifications. This method allows for a high degree of precision and adherence to design…

-

Precision Dispense Solution for a Class 3 Medical Device Implant

Automated precision dispensing is an important process step in many projects we encounter specifically in the medical device, consumer electronics, semiconductor, and battery manufacturing industries. Achieving repeatability in dispensing is non-trivial mainly due to the characteristics of the liquids or suspensions used such as viscosity, surface tension, and setting times. At DWFritz, we have significant…

-

Why Material Handling Stage Design Matters

When high volume manufacturers need 100% inspection of parts, non-contact metrology stage design should not only maximize sensor use, but also easily measure different parts on the same system. Whether it’s ensuring smartphones perform to meet customer satisfaction or precision medical implants function to protect patient health, inspection in manufacturing is key to assuring product…

-

Data Integrity and The Digital Twin

Industrial production technologies are rapidly advancing, and traditional metrology is increasingly turning to non-contact measurement techniques to keep pace. To maintain the higher throughputs required by product demands, production metrology processes are moving from the lab to the manufacturing line, which is driving the emerging trend towards inline metrology and integrated end-to-end production enabling the…

-

Risk Mitigation: From Concept to Production

Risk can be defined as the possibility that an event could adversely affect the achievement of an objective. Automating precision solutions is, in and of itself, a process of identifying, managing, and reducing risk for our clients. The “problem” isn’t taking on risky projects, but is in taking on challenging projects while actively managing the…

-

Improving Product Quality Through Automation

While automating metrology and inspection to improve product quality is not new, the reasons and goals to automate have evolved along with the technology and need. For example, inspection techniques used by contract manufacturers (low-volume/high-mix) versus conventional product manufacturers (high-volume/low-mix) are different. Furthermore, the size and the scale of manufacturing also impact the level of…

-

Five Keys to Executing a Precision Automation Project

Automating advanced manufacturing systems is a complex process that requires careful planning and execution. The right time to automate will depend on several factors, including the nature of the products being manufactured, the size and complexity of the factory, and the availability of appropriate technology and expertise. A phased approach to automation, starting with the…

-

Project Management Ensures Success of Automation Projects

Project managers are vital in planning and executing automation projects, ensuring that high speed assembly and metrology systems are delivered on time and within budget. Automating the metrology and inspection process is a complex job, from reviewing requirements to developing the proof of principle to creating a realistic timeline, and finally, to successfully executing the…

-

Six Key Reasons to Automate Your Manufacturing

Automation is synonymous with advanced manufacturing. Factory automation has been an important ingredient in not only the modern factory, but also in production environments from the past. While many factories are not fully automated, particularly among small- to mid-sized manufacturers, global competition is driving more companies to embrace factory automation to innovate, stay competitive, and…

-

Non-Contact Metrology Platform vs. Traditional CMM

Understanding the features of a non-contact metrology platform versus a traditional contact coordinate measuring machine (CMM) can help manufacturers choose the right equipment for inspection. By investing in the right inspection technology, manufacturers can improve product quality while reducing manufacturing costs. Manufacturers may perform inspection based on a sampling or 100% inspection of the parts.…

-

Improving Yield Using High Speed Non-Contact Metrology

Speed, precision measurements and real-time data from non-contact metrology platforms make a difference in reducing scrap and improving yield for high volume consumer electronics manufacturers. In contract manufacturing, 100% inspection is common, but measuring high volume consumer electronics parts for quality can be challenging. In smartphone manufacturing alone, the production volume can reach up to…

-

Benefits of Consolidating Metrology Operations into One System

Automated metrology platforms not only ensure high quality finished goods, these high speed solutions also lower total cost per part by consolidating multiple metrology operations into one system. High volume part manufacturers often have diverse process flows, and some companies may distribute metrology stations across the factory floor to perform specific measurements. This may result…

-

3 Key Benefits of an Automated Non-Contact Metrology System

In the precise world of advanced manufacturing, microns and milliseconds matter when inspecting class 3 medical devices, fitness trackers and smartphones to meet either government regulations or consumer standards. The need for 100% inspection of parts is driving the medical device, automotive and consumer electronics industries to install automated metrology systems on the factory floor.…

-

Improving Long-Term Performance of Metrology Systems

In challenging manufacturing environments, 3 key factors influence the long-term performance of automated metrology systems installed in uncontrolled environments. Developing a metrology solution that consistently meets demanding production rates, yields and uptime is not something that happens by accident. Building a solid foundation for conducting precision inline inspection for high volume production applications requires 3…

-

Measuring Complex Part Geometries

Tightening dimensions are a trend both for components and for an increasing number of parts and devices. Incorrect part dimensional measurements can lead to failure and costly recalls. Small consumer products pack an enormous amount of technology into tiny units. In smartphones and wearable devices, tolerances are tight, making overall dimensional control critical as more…

-

Speed Wins in Contact vs. Non-Contact Surface Profiling

In surface morphology inspection, non-contact optical methodologies provide the same measurement results as a conventional contact profiler, but in a fraction of time. Surface finish quality matters in many industries, especially when consumer health and costly recalls are at stake. When inspecting medical implants like knee joints, medical device manufacturers need to validate both smooth…

-

Smart Cosmetic Defect Detection Increases Productivity

Using deep learning, smart machine vision systems can inspect complex surfaces and parts for cosmetic defects, increasing manufacturing productivity and throughput. Automated cosmetic defect inspection can be challenging — past efforts with computer vision required brute force methods involving several months of coding and debugging. Today, however, there is a more efficient approach to machine…

-

Ensuring Pharmaceutical and Medical Inspection Compliance with Machine Vision

Machine vision offers an accurate and efficient method of inspecting package seals in medical and pharmaceutical manufacturing, providing companies a means to comply with device testing regulations and avoid costly recalls. In this article, we cover real-life examples of different types of closure seals and the challenges associated with inspecting them, recall concerns and ramifications,…

-

Choosing the Right Lighting for High Speed Inspection

Lighting and timing are key factors when measuring parts in high speed motion. By using short bursts of high intensity lighting, the vision system effectively freezes the motion for inspection. Proper lighting is often the determining factor in the success of high speed part inspection. If the timing overlap is off between the stage motion…

-

Automated Seal Inspection Improves Reliability of Sterile Packaging

Many medical device manufacturers are finding that automated seal inspection improves sterile package reliability, decreasing packaging failure, product contamination and costly recalls. Sterile packaging of medical devices is critical for patient health and safety. Whether it’s packaging for a surgical instrument, joint prosthesis or a heart valve, broken packaging seals can cause product contamination. Other…

-

Automating Complex Dispensing Applications Successfully

Automating precision solutions that overcome complex challenges and consistently meet demanding production goals is no small feat. When that solution requires a complex dispensing application, the task becomes exponentially more challenging. Using a first principles approach, DWFritz’s team of engineers excel at developing precision dispense applications. Taking care to fully capture each clients’ specific requirements,…

-

High-speed Inspection Using Non-contact Metrology

Product quality is vital to customer satisfaction, but performing quality inspections in high-volume or low-volume/high-mix manufacturing presents unique challenges that require precision solutions. Without the appropriate systems and tools for performing high-speed metrology and inspections, manufacturers sacrifice time and efficiency, while increasing the risk of producing defective products that can lead to expensive recalls or…