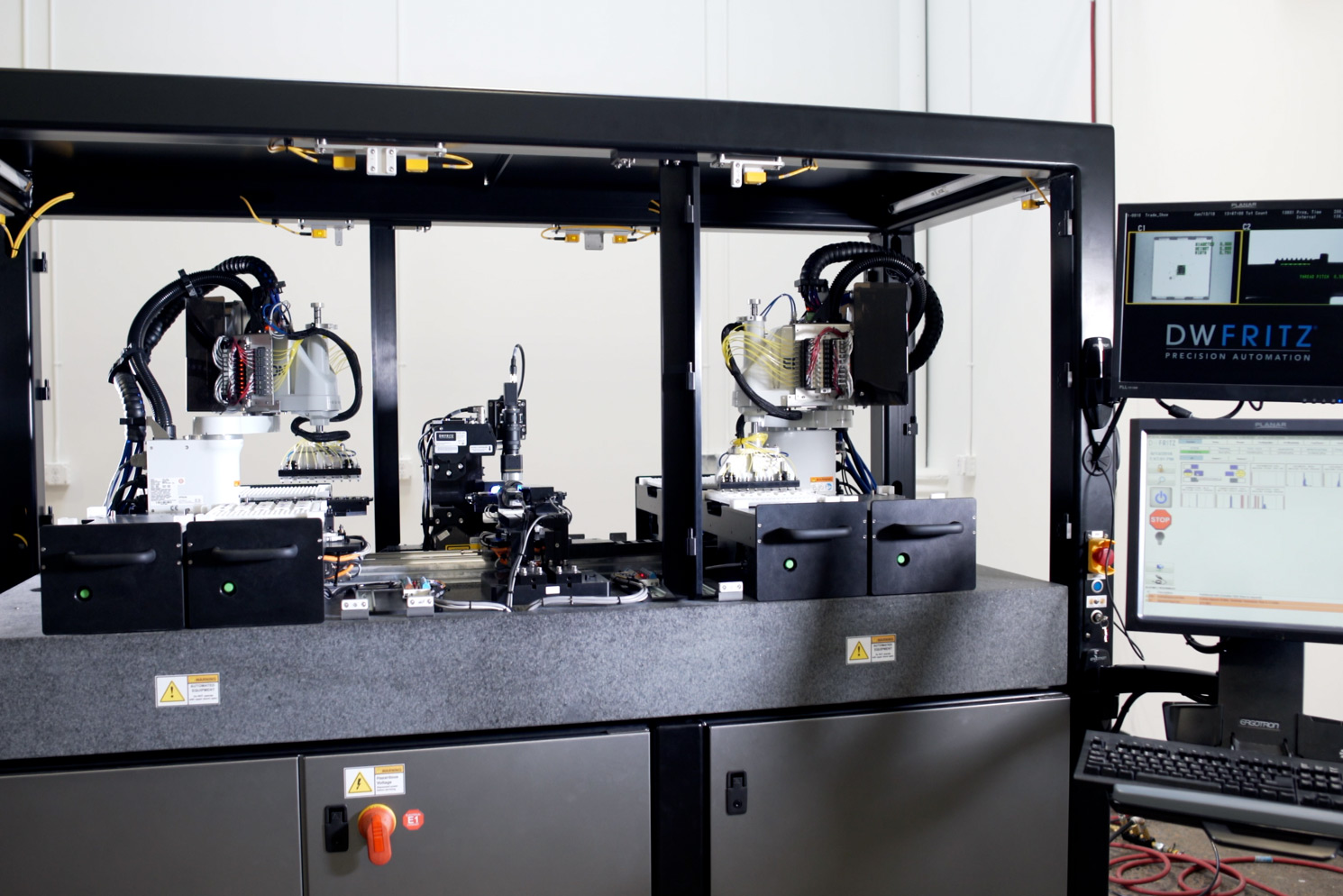

1.5 billion parts inspected, and counting

Automated, high-speed 3D inspection systems built for high-precision small parts in high-volume manufacturing. These non-contact metrology platform combines advanced vision systems, lasers, custom lighting, and robotics to deliver accurate, efficient inspection at scale.

Key Benefits

- High throughput : 4+ parts per second

- Precision non-contact metrology with high repeatability

- Multi-sensor system captures multiple simultaneous measurements

- Generates data for SPC, process optimization and integration with MES

- Low inspection cost per part

- Highly configurable and optimized for customer’s specific applications

- Multi-industry applications

Key Features

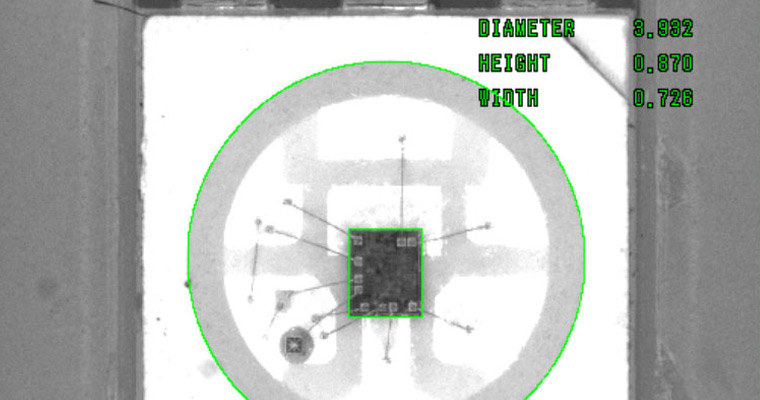

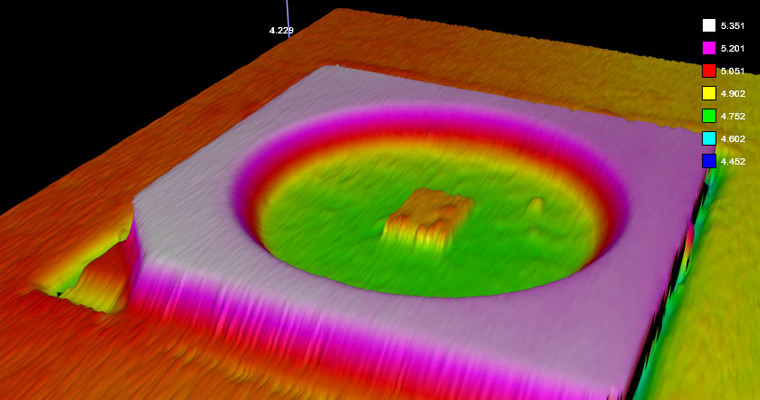

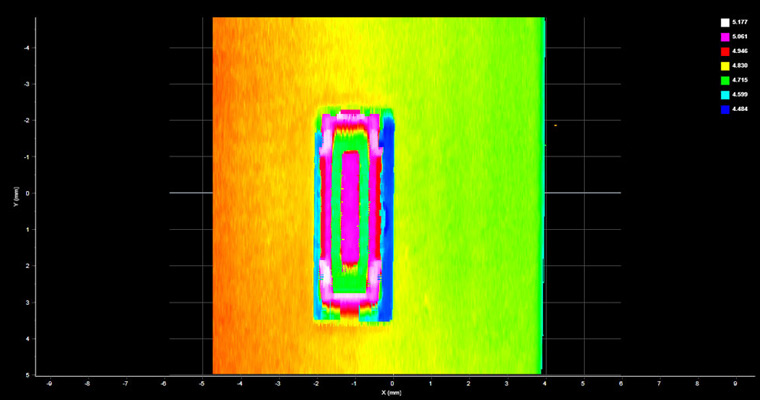

- Metrology platform captures dimensional and angular measurements, and 3D profiles

- Dense point cloud creation

- Cosmetic inspection for defects

- Color and gloss measurements

- Highly customizable platform with options such as – flexible input/output, binning options, laser marking, part programming, and custom fixturing

Specifications

| Work Volume | 200 x 20 x 10 mm (L x W x H) |

| X-axis | 0.7 to 1.0 m active [± 1 μm repeatability] |

| Y-axis | Per requirements [± 1 μm repeatability] |

| Z-axis | Per requirements [± 1 μm repeatability] |

| Payload | 0-2 kg range |

| Pitch, roll, yaw | ± 5 μm Radians |

| Metrology bridge | 1100 mm to 1400 mm |

| Lighting | Custom strobe, coax, ring, color, hybrid |

| Lasers | DWFritz 3D laser modules DLM411 or DLM420 |

| Cameras | 5 MP, 21 MP, monochrome, color |

| Electrical service | 208-240 VAC 50/60 Hz 35A, 1-Phase + GND |

| CDA/AIR service | 1982 l/min [70 CFM] @ 0.6 MPa [90 psi] |

| System dimensions | 236 x 99 x 204 cm (W x D x H) |

| System weight | 2187 kg (4820 lbs) |

| System controllers | High-performance industrial PC operator station with touch screen and secondary display screen |

| Options | – Flexible input and output options (tray, conveyor, bin, and process module interface) – Pre- and post-metrology assembly and processing options, such as adhesives, coatings, and laser marking – Binning – 3D point cloud rendering |