Product quality is vital to customer satisfaction, but performing quality inspections in high-volume or low-volume/high-mix manufacturing presents unique challenges that require precision solutions. Without the appropriate systems and tools for performing high-speed metrology and inspections, manufacturers sacrifice time and efficiency, while increasing the risk of producing defective products that can lead to expensive recalls or poor customer experiences.

To address critical issues with high-speed inspection, many manufacturers are turning to non-contact metrology systems. DWFritz designs and builds solutions using advanced non-contact technologies, including sensors, cameras, and material handling systems coupled with software innovations to overcome these challenges.

So what are some of the key challenges in high-speed inspection?

Speed vs Performance

Cycle times are critical, but maintaining performance at high speeds is a challenge. Lower takt times force manufacturers to consider sampling as a means of inspecting products or parts. Achieving 100% inspection often requires manufacturers to slow down production. Of course, speed without high-quality results would not be worth much. So how do systems achieve high-quality results?

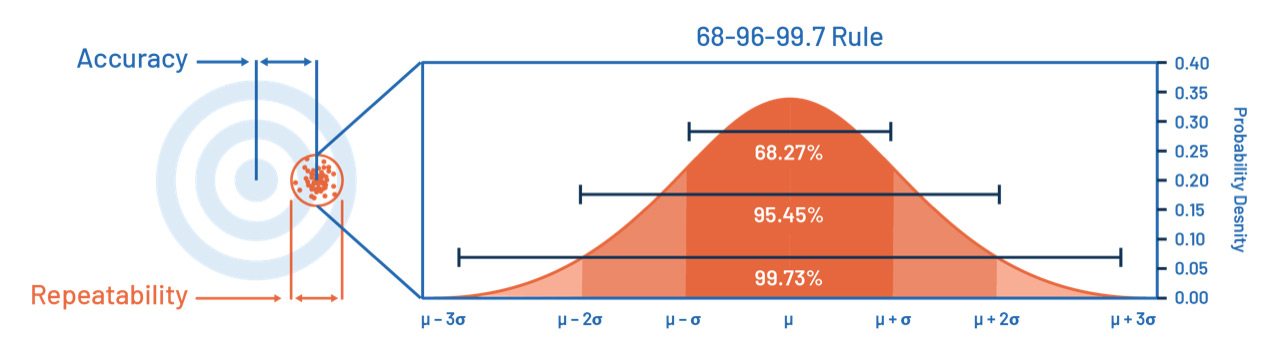

Achieving 10% GR&R

A critical concept in measurement systems, Gage Repeatability & Reproducibility (GR&R) is extremely important in qualifying or validating a measurement device. GR&R is a statistical tool used to describe the inherent variation in a measurement system, which is often the primary contributor to process variation.

By describing the repeatability and reproducibility of a measurement, GR&R provides a measure of how much the output of a measurement system is driven by its variation (or noise). Ideally, GRR would be 0 and the output would precisely correspond to the part being measured. As the GRR rises, the output scatters further from the actual value of the item being measured. Imagine making a decision based on a GRR of 50%. Making that same decision based on a coin toss rather than the measurements themselves would be just as consistent.

One common method of GR&R calculation is called average and range. It is basically the average variation divided by the range of the measurement. The industry standard (AIAG) has evolved such that a good system, generally, is one where the noise is <1%, which corresponds to a GRR of <10%. If the noise is between 1% and 9%, then GRR will be between 10% and 30% – this system is questionable. A poor measurement system has noise >9%, with a corresponding to >30% GR&R.

Ready to begin?

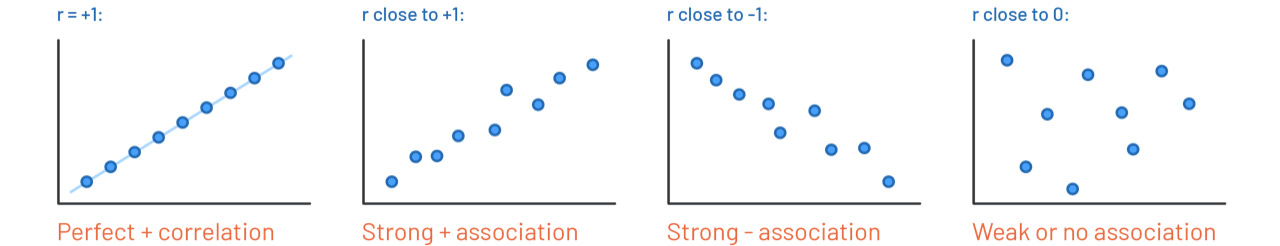

Strong Correlation

Correlation Coefficient (R-value) measures the association between two methods – a method-to-method comparison. We use R-value to determine when a new method of measurement sufficiently agrees with the old method enough to replace it.

R-values range from -1.0 to +1.0, where 1 represents perfect correlation, -1 is perfect negative correlation, and +1 perfect positive correction. An R-value of 1.0 is theoretically possible, as is correlation to a reference measurement system like a CMM, so ideally we want to get as close to 1.0 as possible.

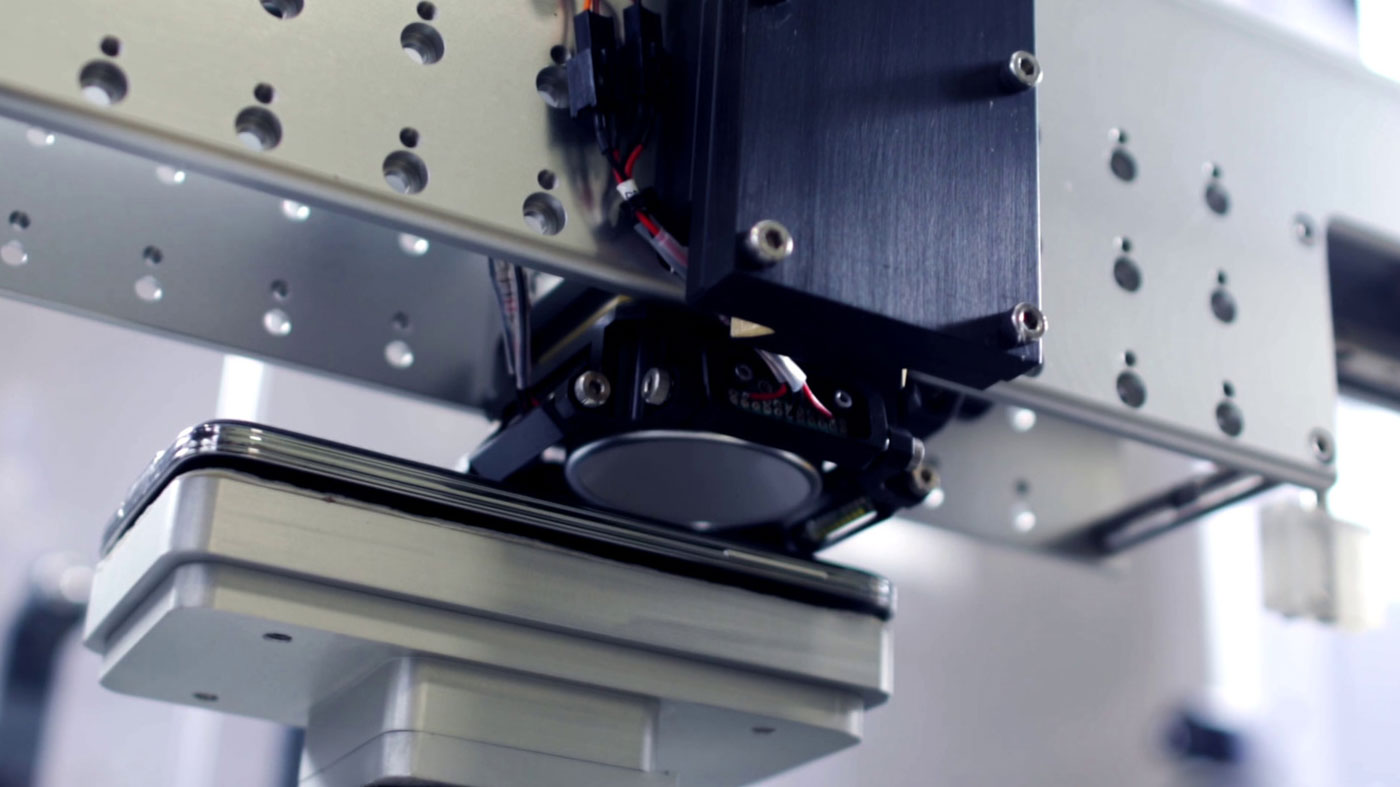

Precision Material Handling

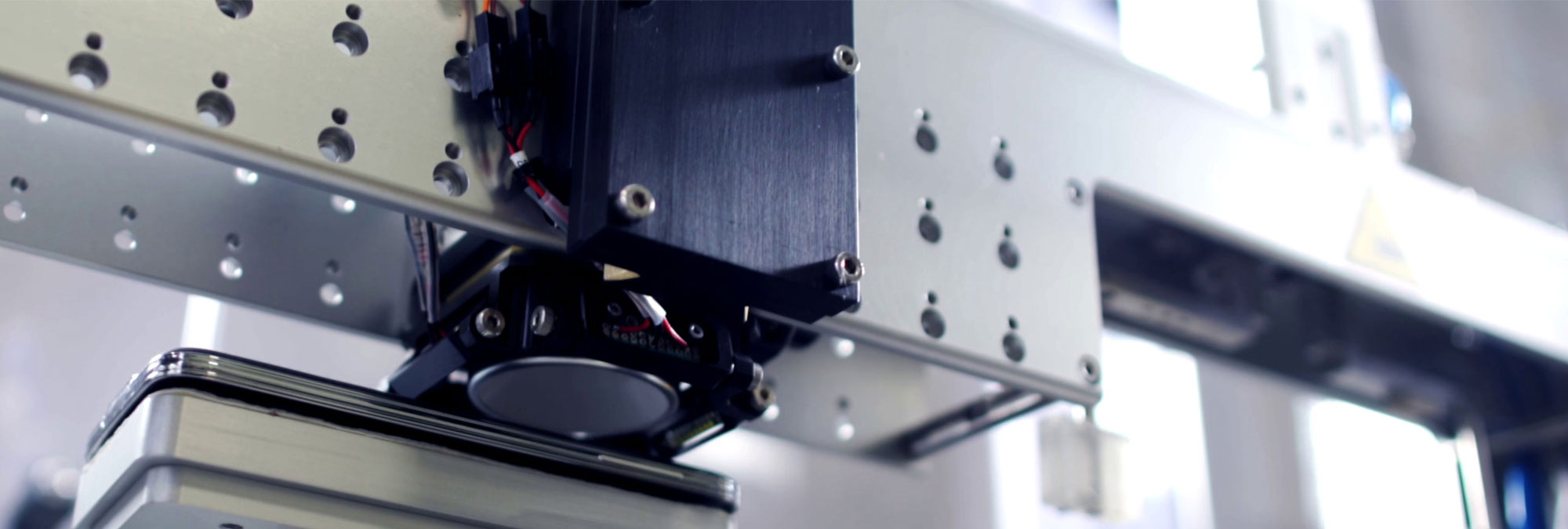

Most people do not think about fixture design and material handling as much as they should, but precision material handling plays a very important role in high-speed, non-contact inspection and repeatability.

Precision fixturing, or holding the part, requires several key characteristics:

- Robust engineered design, particularly for high-value parts.

- Ability to withstand fast, continuous motion to achieve required cycle times.

- Firmly holding, without damaging the part.

Material handling, or articulating the part, must address some key characteristics:

- Rapid movement of part, including high acceleration and deceleration.

- The motion stage (or axis) must be highly engineered to prevent compromising repeatability.

- Present part at right time and orientation to non-contact sensors.

Systems Integration

Analytics and integration with Manufacturing Execution Systems (MES) is a vital component in high-speed inspection, particularly as manufacturers move closer to Factory 4.0 environments. Integrating with MES enables upstream and downstream process steps to be continually optimized in order to ensure GD&T are within specs.

Solving Industry Challenges

Production facilities typically employ three types of inspection: In-line, Near-line, and Offline. In-line inspection is 100% inspection and is a perfect fit for high-speed, non-contact metrology. Near-line uses inspection systems near the line with results based on sample rates. Finally, offline inspection is associated with much lower sampling rates and typically done in a lab.

With production volumes up to >100 million parts per year in many instances, quality inspections in consumer electronics manufacturing can be a major challenge. The semiconductor industry also commonly uses 100% inspection for wafer production, in particular. High manufacturing volume alone, however, does not necessarily imply 100% inspection, but high product value and high production volume demands it.

Highly regulated industries, such as Aerospace (FAA) and Medical Devices (FDA), require 100% inspection due to human risk factors. Though lower in production volume, high value parts such as medical implants or airplane components require precision inspection and material handling. Automated inspection is very helpful in these use cases, as manual inspection is unreliable (to achieve 6-σ defect levels), increases risks, and is often more expensive in the long run.

Ready to begin?

Use Cases

In the section, we examine two use cases where DWFritz integrated advanced technologies to develop high-speed, non-contact metrology and inspection systems to overcome inspection challenges and to meet our customers’ stringent criteria.

Use Case: Hand Held Devices

A consumer electronics customer with an extraordinary commitment to quality that has become part of its brand needed to inspect and sort 100% of the components that go into their device. Their current, manual process required scores of people and a lot of floor space to inspect and sort parts into multiple different sizes for downstream processes. The challenge presented included:

- Extremely high volume (>100M parts per year) and throughput (~2 seconds per part)

- Close to 1,000 measurement points per part

- Micron-level tolerances ranging from 20-200 microns

- Platform consisting of multiple configurable metrology modules

- Binning of parts based on measurement results

DWFritz engineers developed a system featuring a variety of metrology sensors and custom strobe lighting using specially designed sensor mounting brackets for modularity and configuration. The system included four different triangulation lasers, two different confocal sensors, multiple 2D cameras, and color and gloss sensors to inspect nearly 1,000 unique features at 2 seconds per part. Machine vision was used for part tracking on conveyors going in and out of the tool for part sorting. With hundreds of machines in operation, our non-contact metrology solutions perform more than 1.8M measurements per hour (more than a billion per year) with parts that never stop moving.

Use Case: Precision Medical Implants

A medical device customer came to us with a small part inspection challenge. They needed 100% inspection of 30 features at a rate of four parts per second for very small medical screws with micron level tolerances. The challenge presented included:

- High volume manufacturing (>500M parts) and throughput (4 parts per second)

- Up to 30 measurement points per part inspected

- Micron-level tolerances ranging from 20-80 microns

To answer the call, DWFritz developed one of our flagship products, the AMP 3100. Using a 2-nest design to load or unload one nest while inspecting the other, the AMP 3100 uses strobed lighting and maximizes sensor utilization for continuous motion inspections. The system can pick-and-place up to eight parts at a time to perform 432,000 discrete measurements per hour.

The systems designed in the outlined use cases have several key components in common:

- Non-contact 3D sensors that can “Measure parts in Motion”

- Precision material handling

- Machine vision

- Custom lighting

- Fully integrated, multiple sensors

- Modular, full-custom software

Non-contact metrology systems are not just for measuring dimensions and geometries. Our solutions can identify defects on a wide variety of surfaces and materials, perform surface roughness measurements, label inspection, and perform package and seal inspection for foreign materials, seal integrity, packaging breaches, and content verification.

Most importantly, these non-contact metrology techniques and technologies alleviate the most vexing challenges in high-speed inspection and defect detection. Such solutions offer micron-level accuracy, speed, and the flexibility for multiple manufacturing environments by integrating configurable metrology modules using multiple 2D/3D sensors and precision material handling.

Non-contact Inspection and DWFritz

Systems based on non-contact metrology provide a superior solution to challenges posed in not only high volume manufacturing, but also in low-volume/high-mix production environments. Non-contact systems integrate a variety of enabling technologies such as sensors, advanced material handling, custom lighting and machine vision.

DWFritz’s unique capabilities and expertise in this area allows us to excel in solving our customers’ most difficult inspection and advanced manufacturing challenges.