Your one-stop shop for battery manufacturing Automation

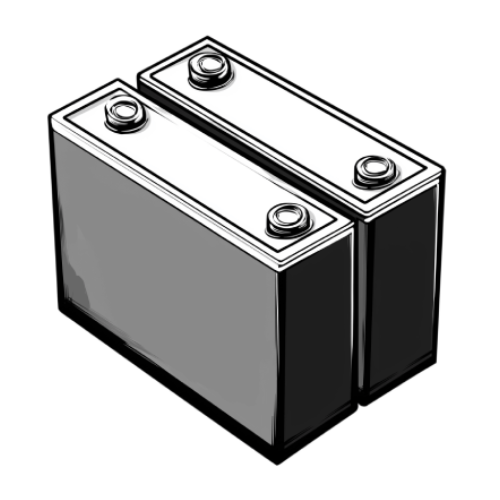

DWFritz offers a full range of solutions to manufacture battery cells, modules and packs for small and large-scale projects. Our work involves the development and use of advanced manufacturing technologies to ensure the quality, reliability, and performance of batteries used in industry verticals such as Automotive & E-Mobility and Energy Storage & Battery.

From developing our own high-speed battery stacker to delivering full battery manufacturing lines, we have the expertise and experience to provide Automation for all stages of the EV battery fabrication process.

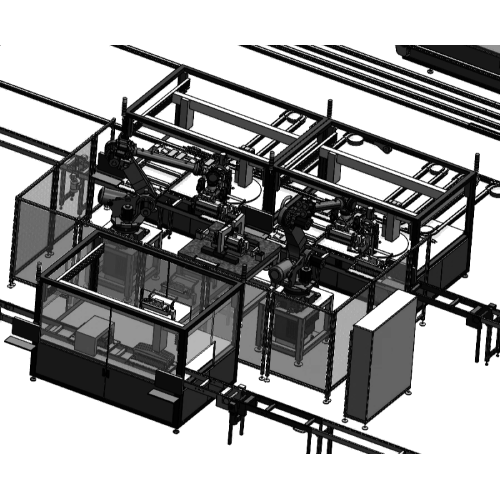

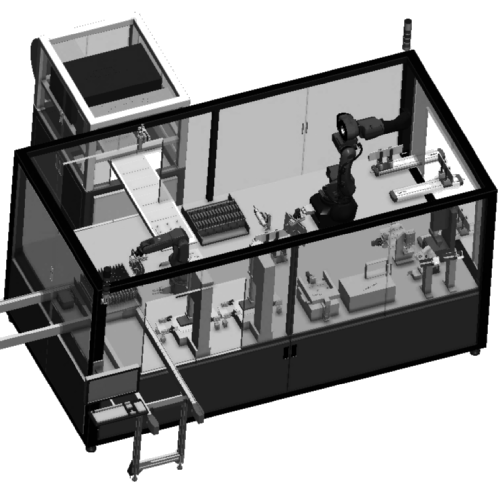

The battery assembly process encompasses several critical stages, including cell manufacturing, module and pack assembly, inspection, and testing. Our expertise has enabled many of our customers to bring innovative products and solutions to market. We specialize in high-speed integration and assembly of cells using our advanced vision systems, Digital Twin, Artificial Intelligence, bonding, dispensing, end-of-line testing, and laser & ultrasonic welding. The integration of end-of-line testing ensures that each battery meets stringent quality standards before it reaches the market.

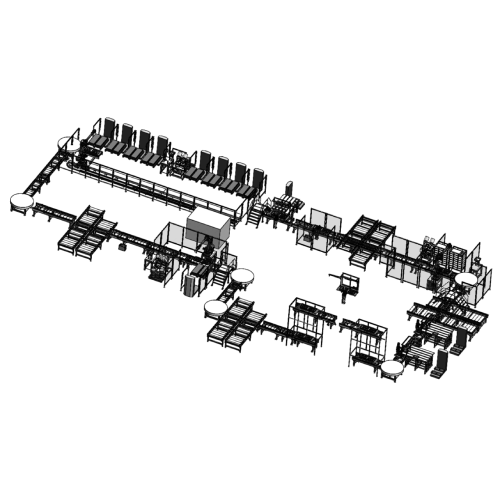

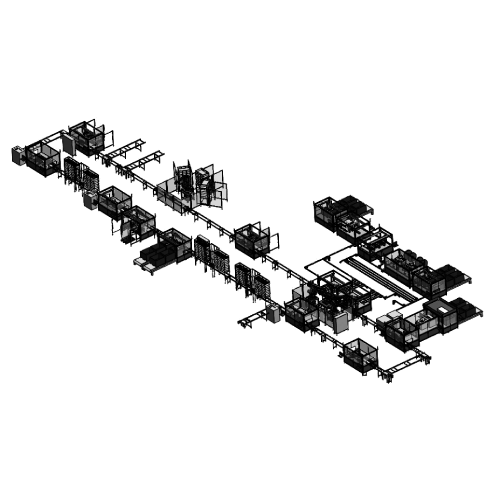

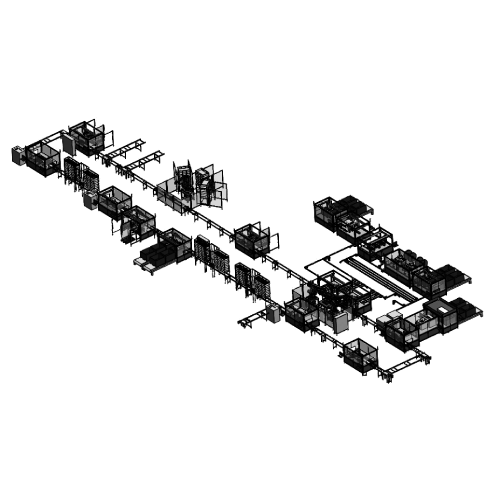

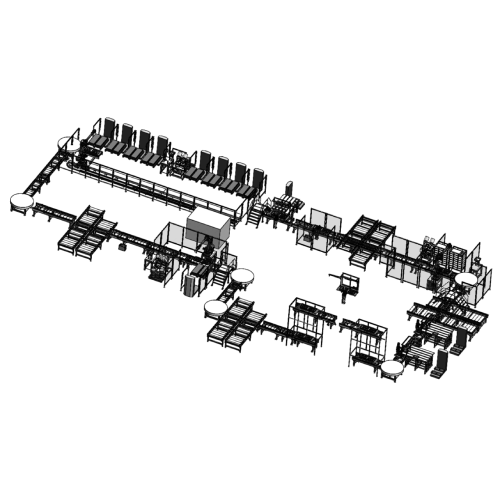

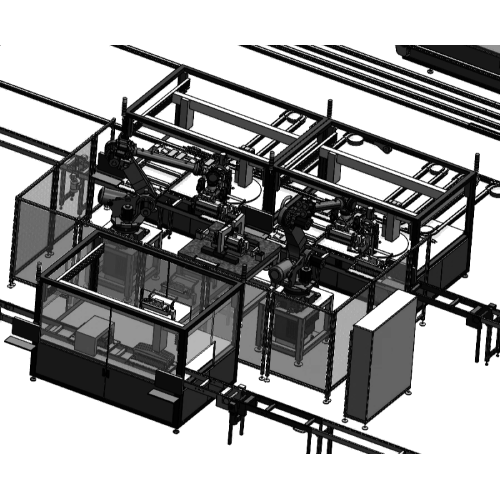

EV Battery Production Line

Explore the animation below to learn more about our battery manufacturing process.

Drying and Calendaring

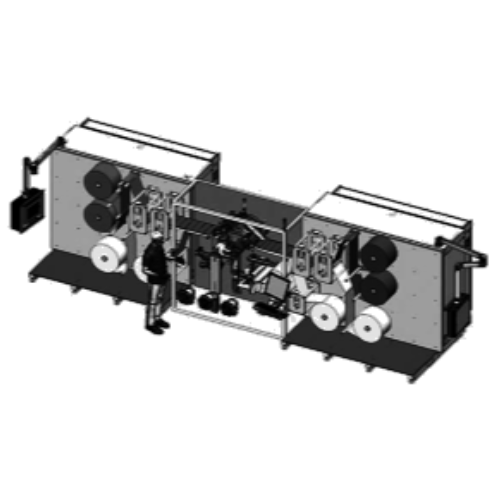

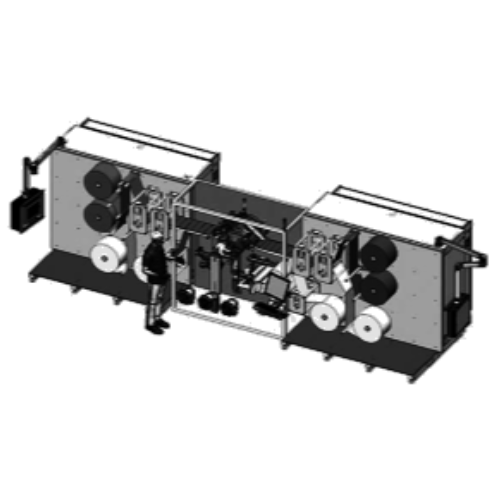

Notching and Slitting

Electrolyte Filling

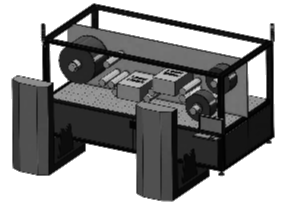

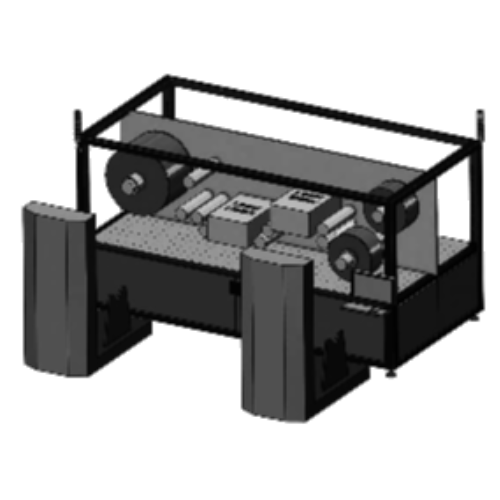

Stacking

Pouch Formation / Sealing

Formation and Aging

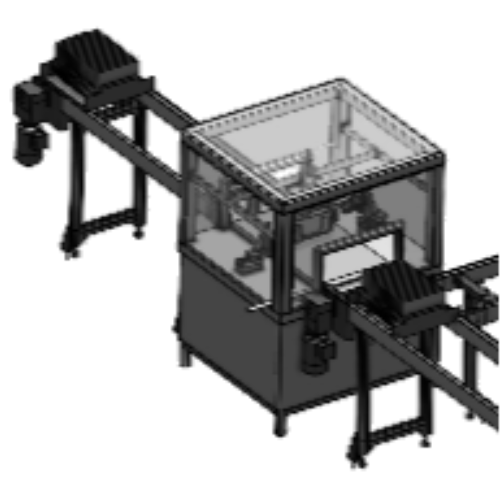

Pack Assembly

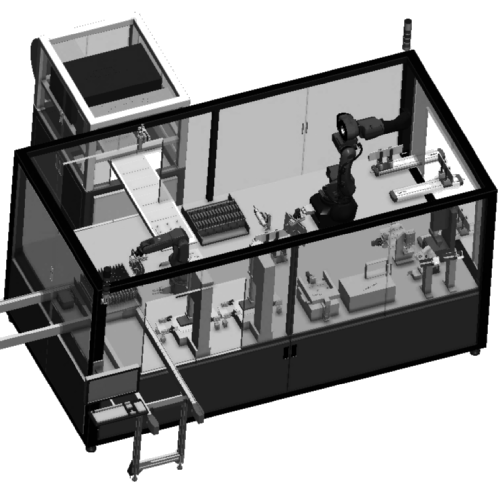

Module Assembly

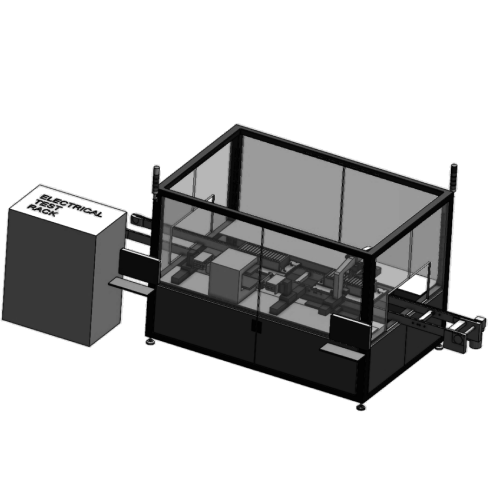

Electrical Test

Final Inspection

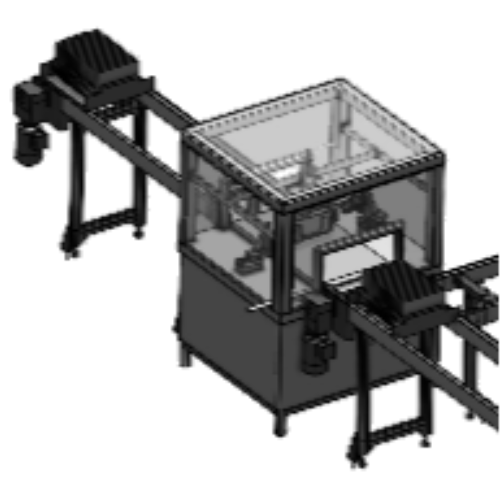

Electrode & tab inspection with digital twin

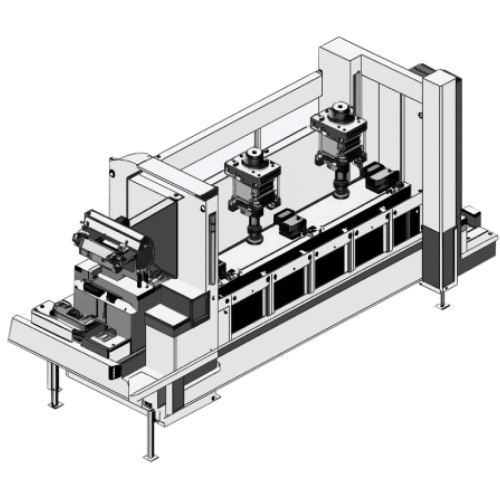

Singulated electrode & separator stacking

Material feed systems

Traceability

100% pure and post stacking inspection

Electrode & tab inspection with digital twin

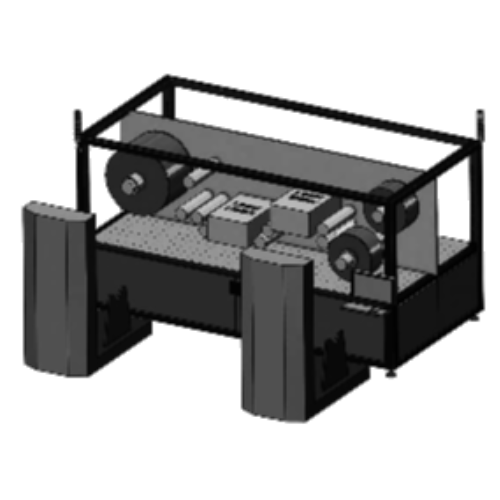

- “Operator load or AGV delivers jumbo roll to unwinder

- Manual roll to roll splicing

- Laser or mechanical notching of electrodes

- Notched tab dimensions inspected

- Notch cleaned by ionizers and suction”, “Laser or mechanical roll slitting

- Roll material inspected for slitting dimensions

- Roll material cleaned by ionizers and suction”, “Dual output roll winding

Drying and Calendaring

Notching and Slitting

Stacking

Electrolyte Filling

Pouch Formation / Sealing

Formation and Aging

Module Assembly

Pack Assembly

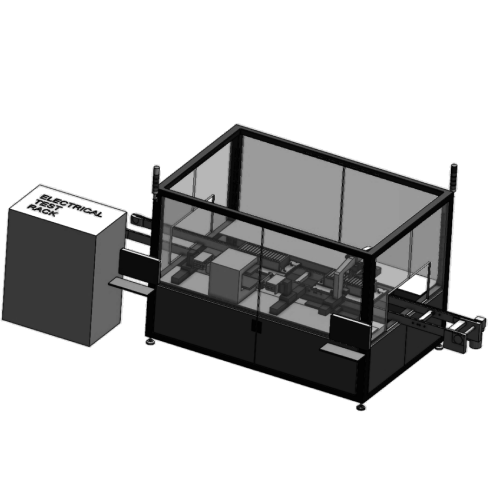

Electrical Test

Final Inspection

Learn more about Battery Assembly

Fully Automated Battery Manufacturing

With more than 20 million electric vehicles expected to hit the market by 2030, the automotive industry alone is significantly increasing demand for new products and technologies in the battery…

The Journey of a Product with Contract Manufacturing

The journey of a product begins with a concept, an idea that has been vetted by customers. For products in the physical space, this idea then becomes a set of…

Scaling Up to a Smart Factory with Automated Assembly

Automated assembly stations provide higher productivity and product quality while lowering product cost in a fraction of the space required for conventional tooling. Staying competitive in the drive toward smart…

Six Key Reasons to Automate Your Manufacturing

Automation is synonymous with advanced manufacturing. Factory automation has been an important ingredient in not only the modern factory, but also in production environments from the past. While many factories…

Fully Automated Battery Manufacturing

With more than 20 million electric vehicles expected to hit the market by 2030, the automotive industry alone is significantly increasing demand for new products and technologies in the battery…

The Journey of a Product with Contract Manufacturing

The journey of a product begins with a concept, an idea that has been vetted by customers. For products in the physical space, this idea then becomes a set of…

Scaling Up to a Smart Factory with Automated Assembly

Automated assembly stations provide higher productivity and product quality while lowering product cost in a fraction of the space required for conventional tooling. Staying competitive in the drive toward smart…

Six Key Reasons to Automate Your Manufacturing

Automation is synonymous with advanced manufacturing. Factory automation has been an important ingredient in not only the modern factory, but also in production environments from the past. While many factories…