Where semiconductor challenges meet custom automation

At DWFritz, we design and deliver high-precision automation, metrology, and inspection systems engineered for the exacting demands of wafer fabrication and backend assembly. When standard solutions can’t meet throughput or accuracy requirements, our team builds custom, end-to-end systems that perform with unmatched reliability and micron-level precision. From front-end processing to backend packaging, we help semiconductor manufacturers scale with confidence.

Ready to begin?

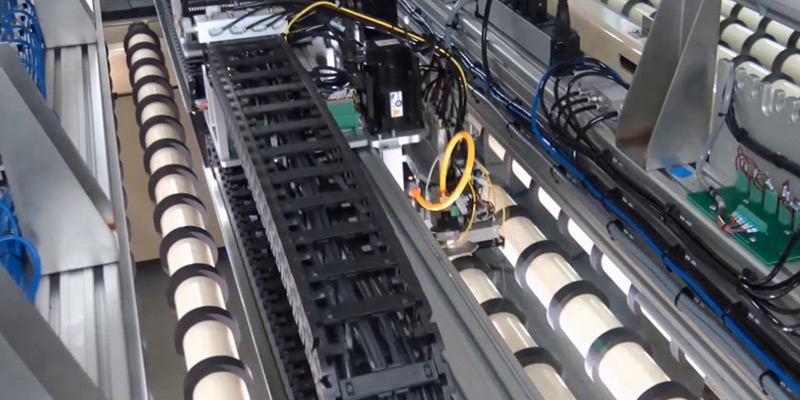

Advanced binning & sorting solutions for semiconductor manufacturing

Built for the complexity of semiconductor assembly, our systems deliver precision at scale:

- Custom 2D/3D Vision Systems: Designed for detailed inspection and alignment

- Precision Lighting: Engineered to optimize image clarity and contrast

- High Accuracy: Achieves micron-level precision in sorting and classification

- Repeatable Performance: Consistent results across high-volume production

- Optimized for Speed: Maintains throughput without sacrificing precision

Ultra-precise systems for wafer metrology and assembly

We engineer advanced systems that meet the micron-level demands of semiconductor manufacturing:

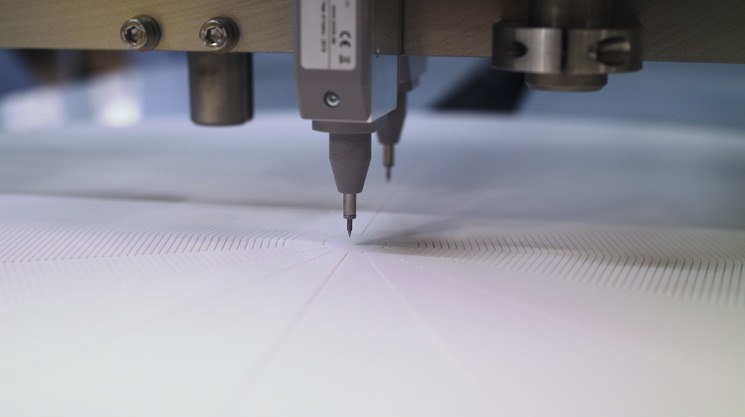

Metrology Accuracy: Detect and measure wafer features with up to 1μm precision using high-resolution vision systems and laser interferometers

Assembly Alignment: Vision-guided systems align components with exceptional accuracy

Adhesive Dispensing: Apply adhesive dots to silicon wafers with placement accuracy up to 20μm

Custom-Engineered Solutions: Every system is built to meet the unique specifications and throughput requirements of each fab

Improve manufacturing yield

Our precision-engineered systems are designed for high-throughput semiconductor environments, improving yield without compromising space or speed.

This system features a parallel processing architecture to maximize throughput, ceiling-mounted robotics to preserve cleanroom floor space, and high-intensity lighting for enhanced image contrast. Real-time information systems ensure seamless integration with MES and traceability platforms, while automated binning and sorting deliver efficient, cleanroom-optimized handling.