Transforming MedTech through precision automation

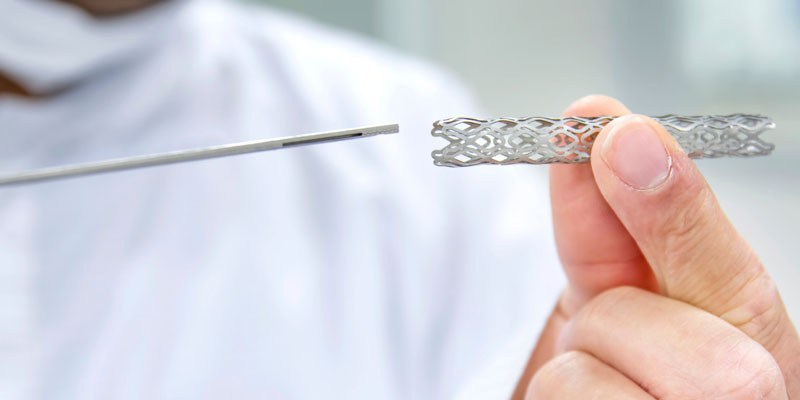

DWFritz enables the production of complex, miniaturized, and highly regulated medical devices through advanced automation. With decades of experience in high-speed assembly, nanoliter dispensing, and sub-micron inspection, we help MedTech and life sciences manufacturers improve outcomes, accelerate innovation, and ensure compliance.

Ready to begin?

Advanced automation for medical & life sciences

DWFritz delivers fully integrated solutions for assembly, dispensing, and inspection across medical, diagnostic, pharmaceutical, and biotech applications. Our systems are engineered to support precision, compliance, and repeatability at scale.

Key capabilities include:

- Engineer-to-Order Platforms: Custom automation designed to meet ISO 13485 and other regulated manufacturing standards

- Proof of Principle (PoP): Early feasibility testing to validate automation concepts and reduce risk

- FMEA Support: Failure Mode and Effects Analysis integrated into system design

- Qualification-Ready Systems: Engineered for streamlined IQ (Installation Qualification), OQ (Operational Qualification), and PQ (Performance Qualification)

- Traceability & Compliance: Full documentation and system validation to support regulatory audits and lifecycle quality control

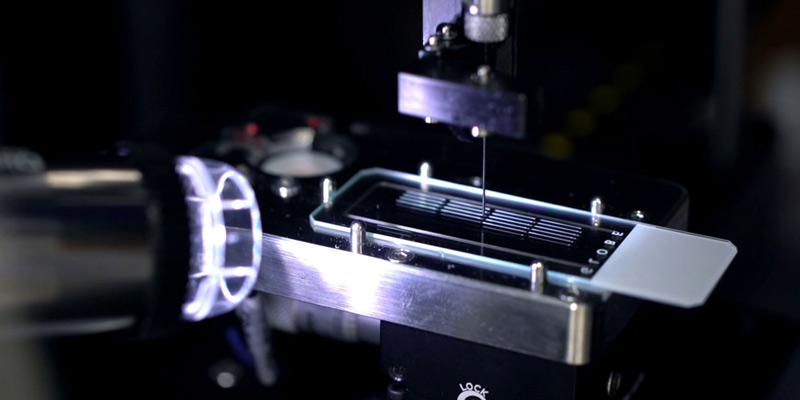

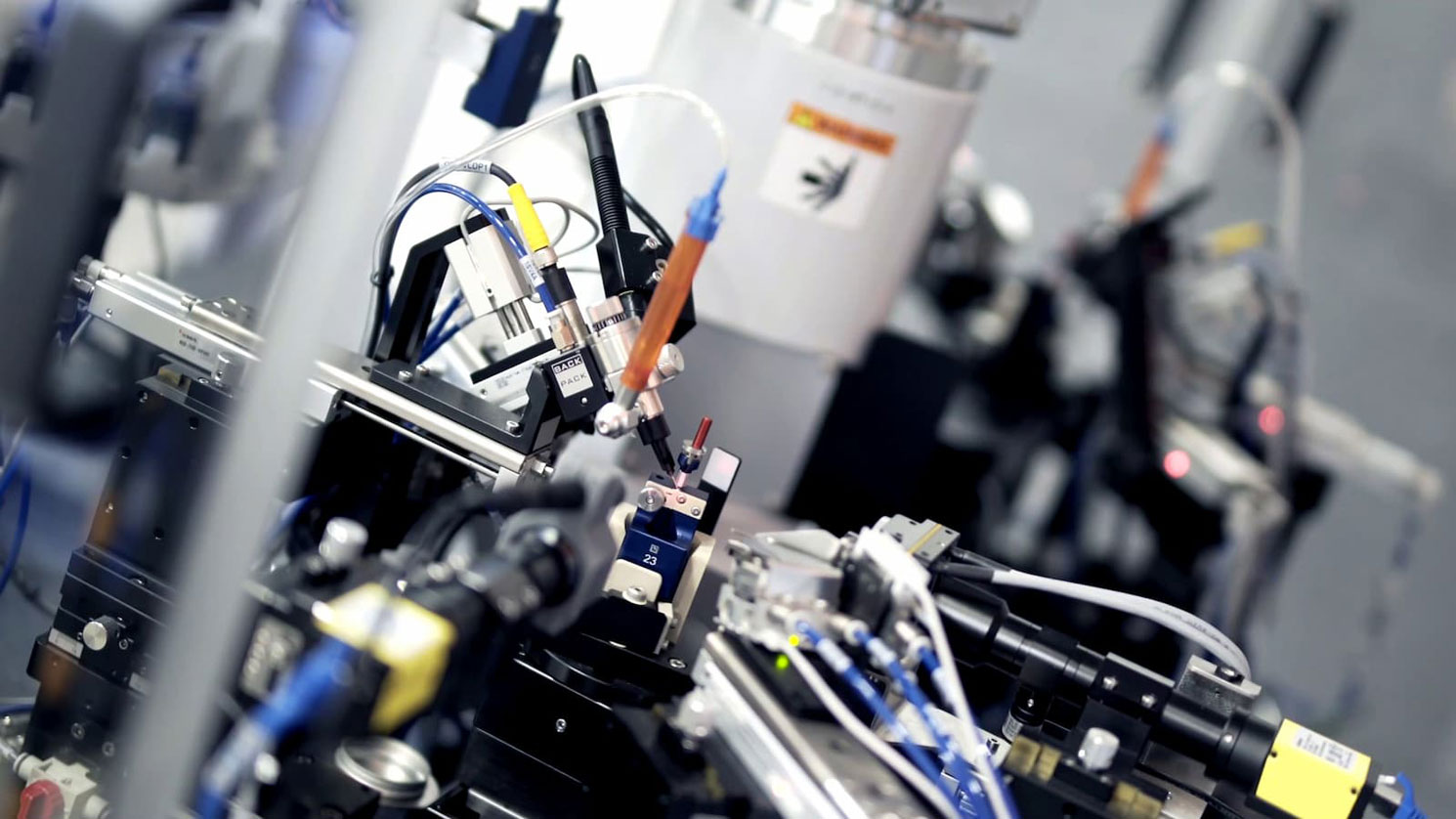

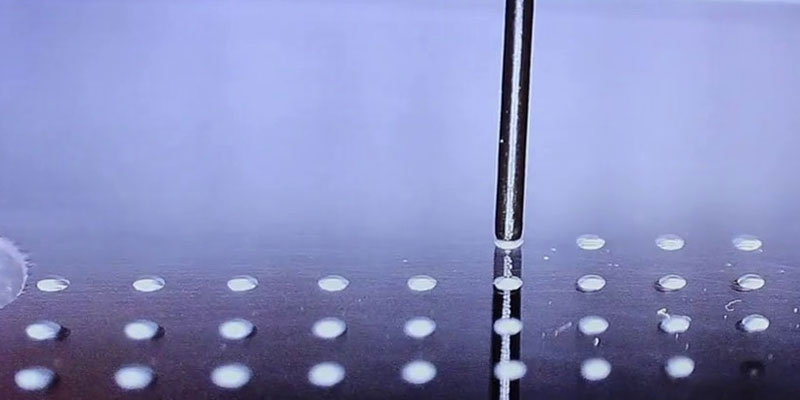

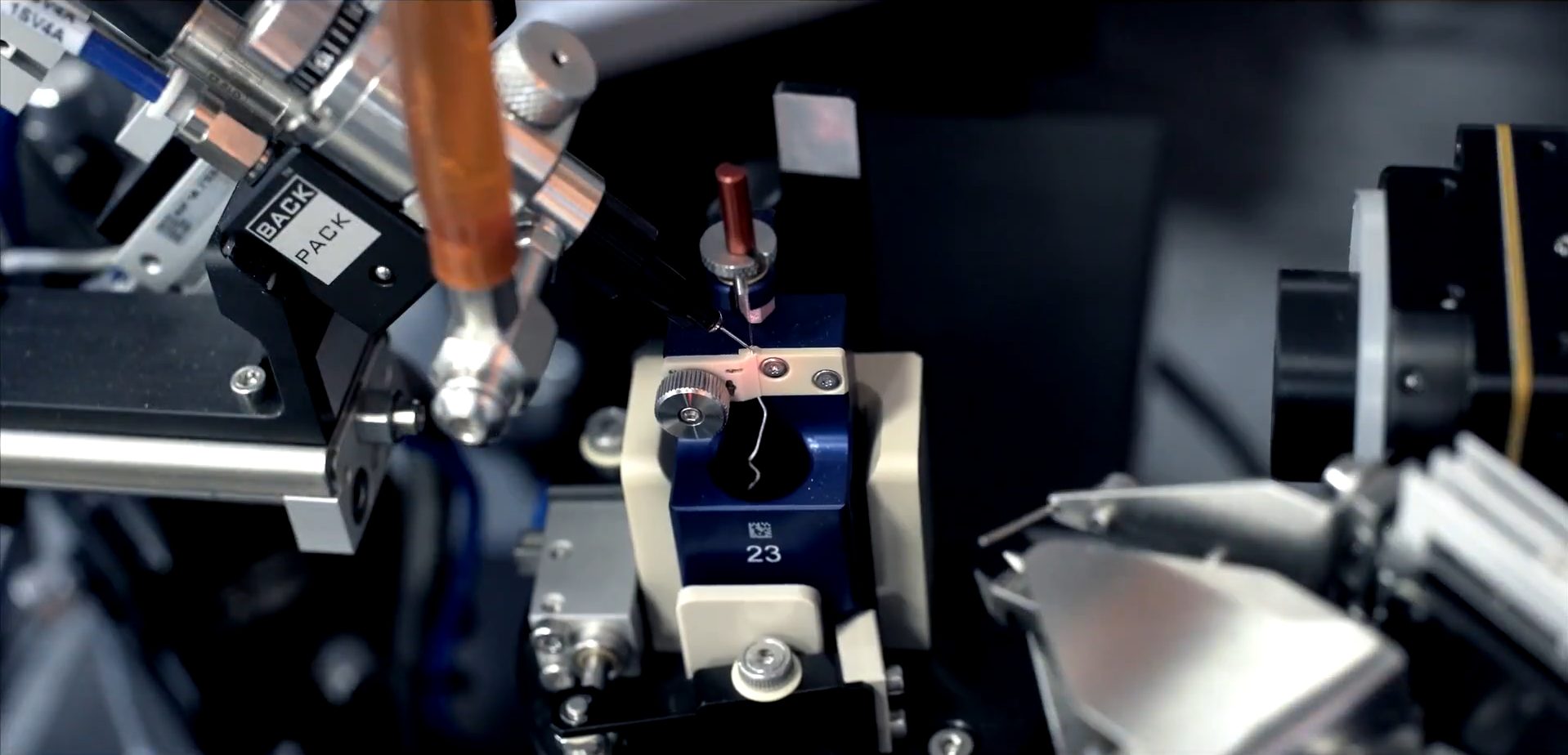

Consistent dispense accuracy

DWFritz Automation delivers high-precision, closed-loop dispensing solutions that maintain nanoliter accuracy in critical life sciences applications. Our real-time process control systems detect and correct dispensing deviations, ensuring repeatability, waste reduction, and compliance with industry standards.

With proprietary fixturing and vision-guided dispensing, our systems enable precise volume control for drug delivery systems, microfluidics, and medical adhesives. Designed for scalability and integration into regulated manufacturing environments, our dispensing solutions enhance process reliability while supporting regulated manufacturing environments.

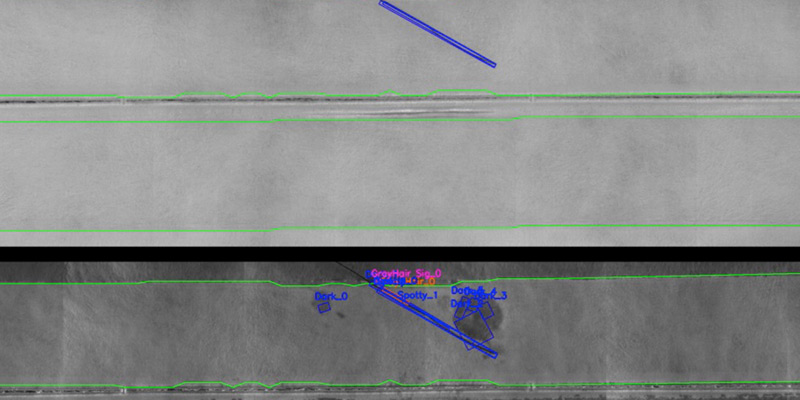

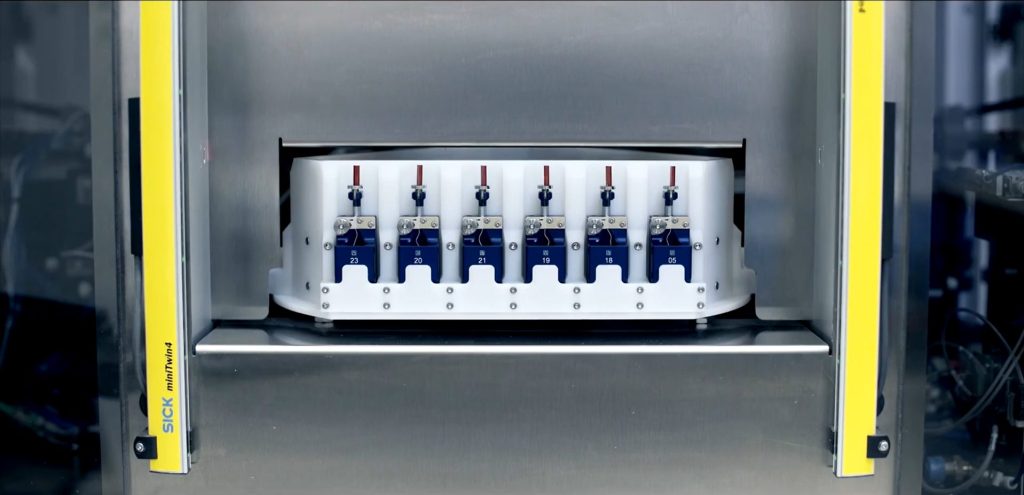

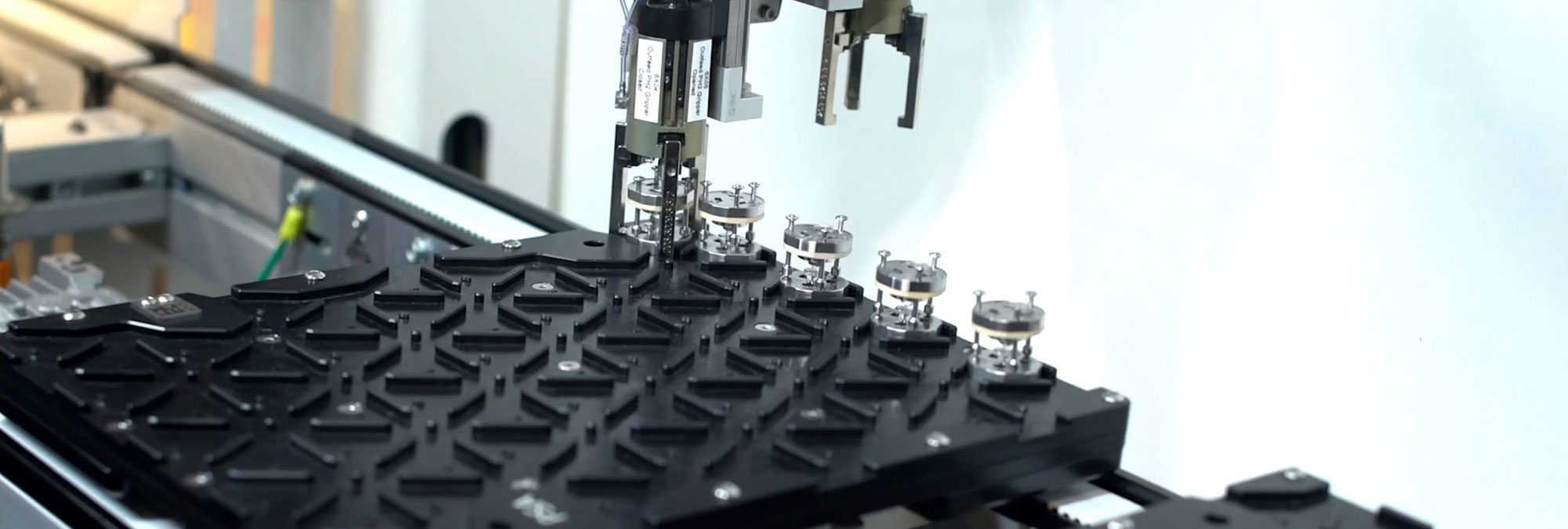

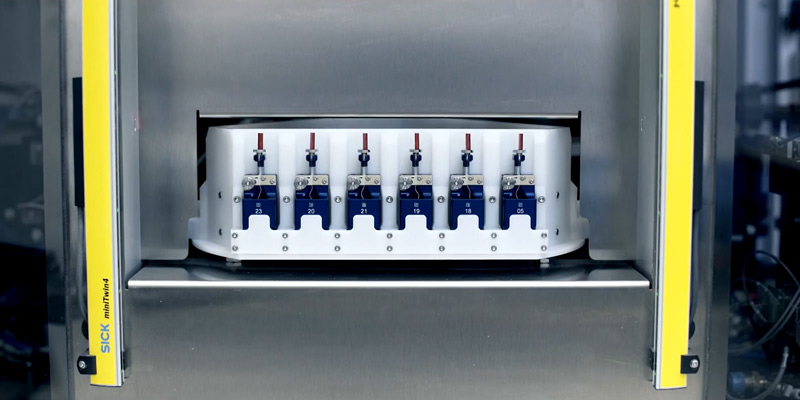

Automated material handling & inspection

DWFritz develops high-speed material handling and inspection systems purpose-built for life sciences and medical manufacturing. Our solutions are designed to handle fragile, high-value components with precision and care—while maintaining the throughput and traceability required in regulated environments.

Using high-resolution imaging and advanced vision systems, our inline inspection technology detects over 40 defect types, including micro-contamination, dimensional variation, and misalignment—at production speeds up to 250 mm/sec.

Supporting Class III medical compliance

Explore our case study on a Package and Label Inspection System designed to ensure pharmaceutical and medical packaging meets the highest standards of accuracy, safety, and cleanliness.