Powering the future with precision energy & battery production lines

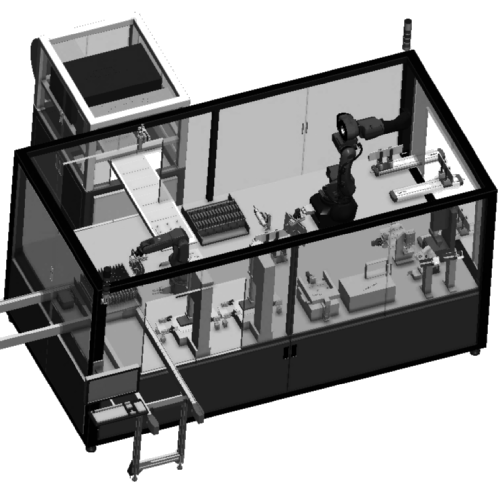

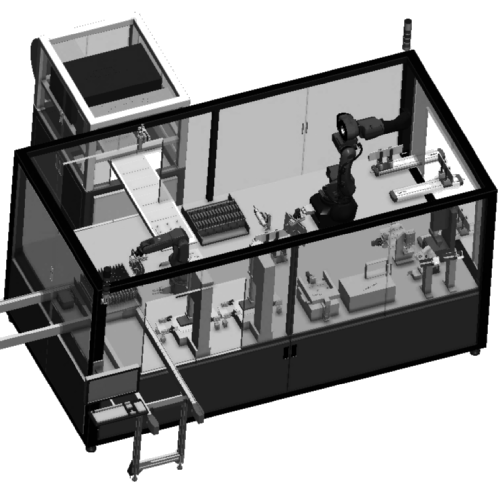

DWFritz designs advanced automation systems to assemble, inspect, and test batteries for high-performance energy storage applications. From battery cell manufacture to discrete battery cell application, our solutions ensure the precision, reliability, and scalability manufacturers need to meet evolving demands.

Ready to begin?

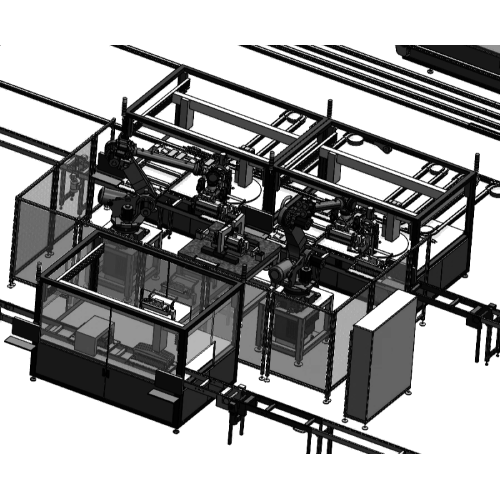

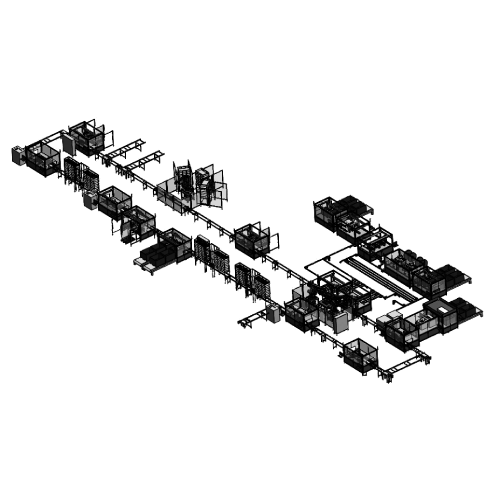

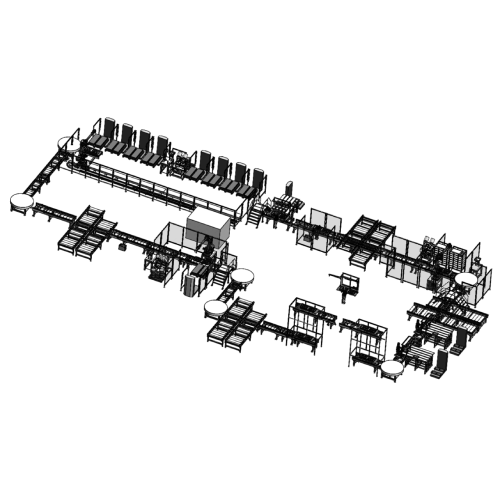

End-to-end expertise in battery assembly

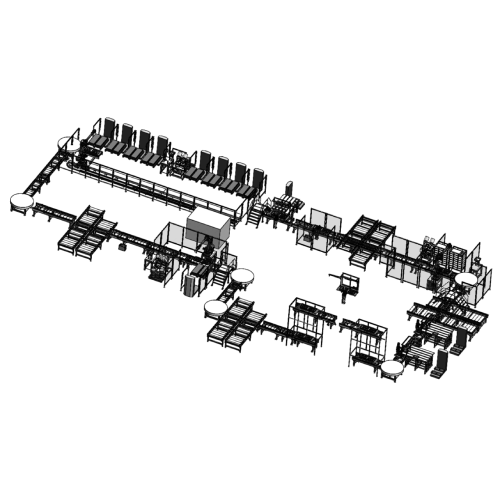

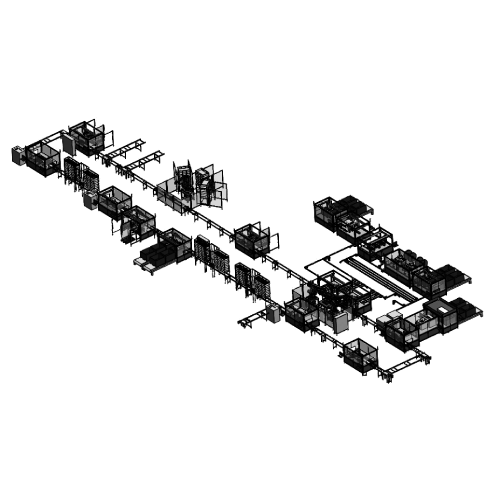

From developing our proprietary High-Speed Electrode Stacking System to delivering full-scale energy storage manufacturing lines, DWFritz brings deep expertise in building battery cells, modules, and packs—across a wide range of chemistries and form factors.

Battery Manufacturing Process

Drying and Calendaring

Notching and Slitting

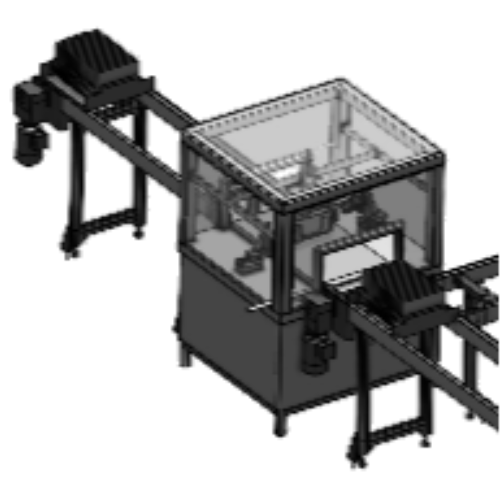

Electrolyte Filling

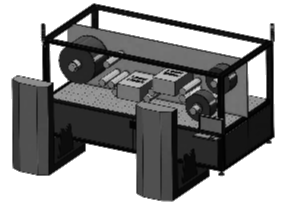

Stacking

Pouch Formation / Sealing

Formation and Aging

Pack Assembly

Module Assembly

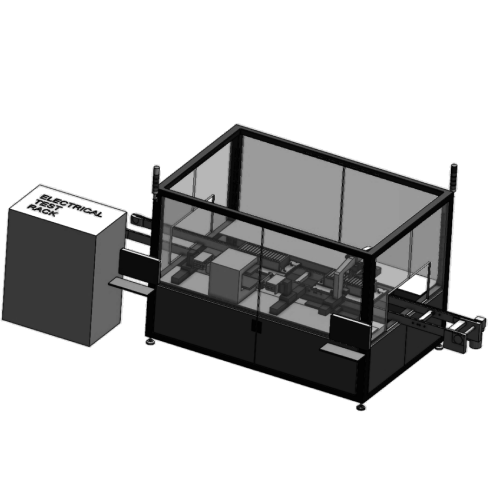

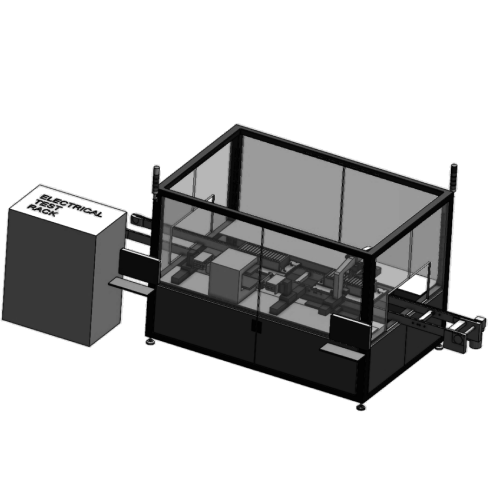

Electrical Test

Final Inspection

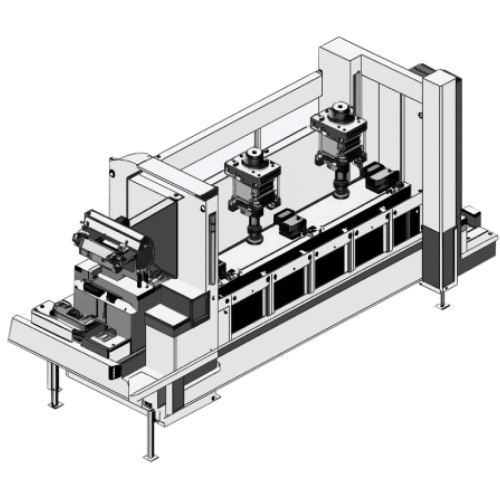

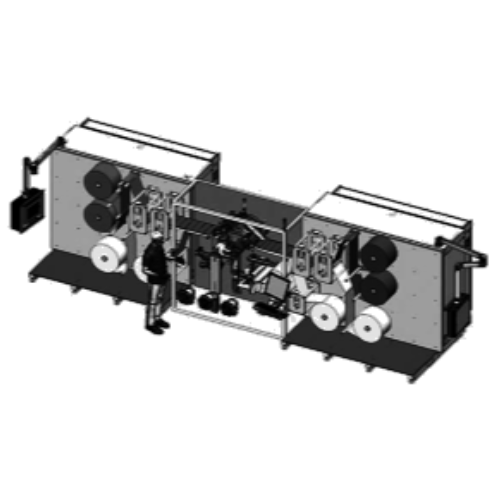

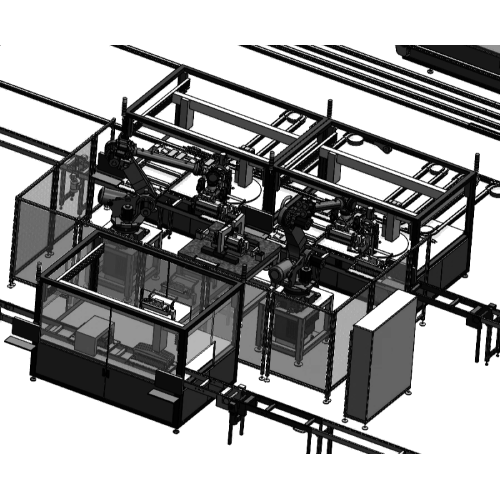

Electrode & tab inspection with digital twin

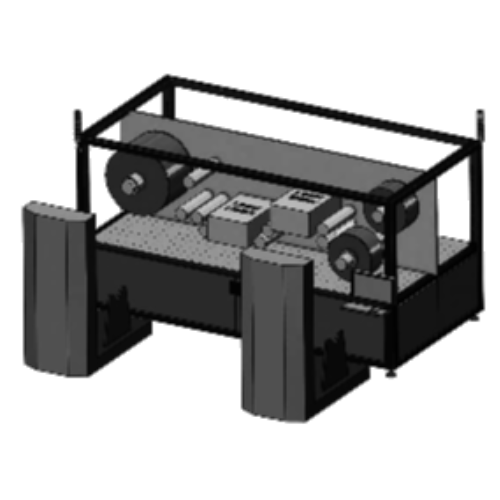

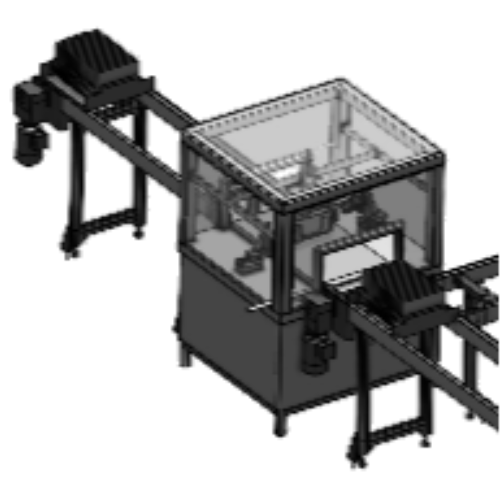

Singulated electrode & separator stacking

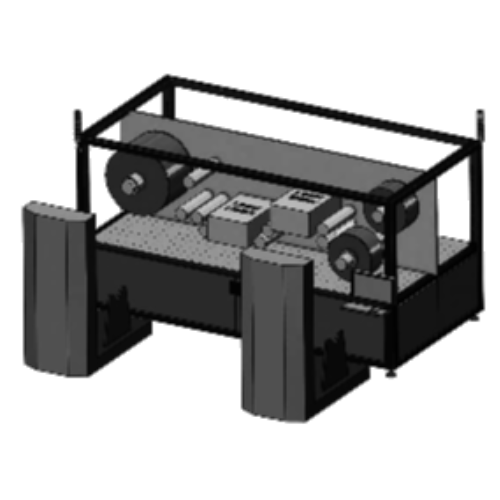

Material feed systems

Traceability

100% pure and post stacking inspection

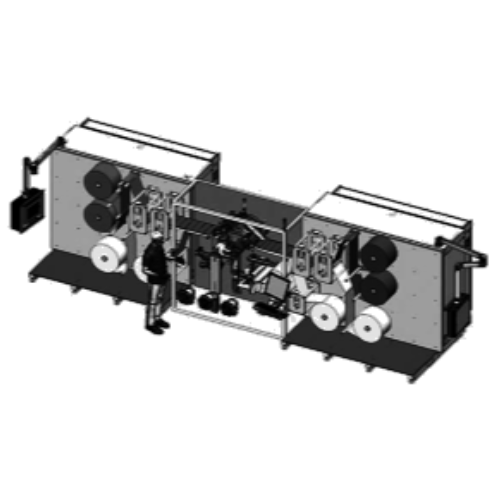

Electrode & tab inspection with digital twin

- “Operator load or AGV delivers jumbo roll to unwinder

- Manual roll to roll splicing

- Laser or mechanical notching of electrodes

- Notched tab dimensions inspected

- Notch cleaned by ionizers and suction”, “Laser or mechanical roll slitting

- Roll material inspected for slitting dimensions

- Roll material cleaned by ionizers and suction”, “Dual output roll winding

Drying and Calendaring

Notching and Slitting

Stacking

Electrolyte Filling

Pouch Formation / Sealing

Formation and Aging

Module Assembly

Pack Assembly

Electrical Test

Final Inspection

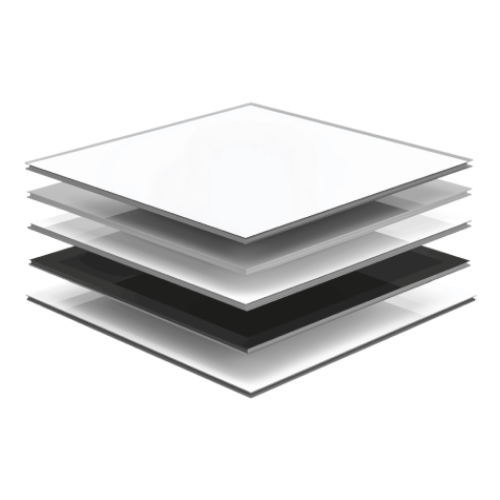

Micron-Level Accuracy in Battery Manufacturing

DWFritz brings deep expertise in building fully automated, high-speed battery lines with micron-level stacking precision. Our systems integrate advanced material handling, web handling, and motion control to ensure exact alignment of cells—crucial for maximizing energy density, performance, and consistency.

See it in action

Explore how we helped accelerate battery production with a high-throughput, precision-automated assembly line in our Battery Cell Production case study.