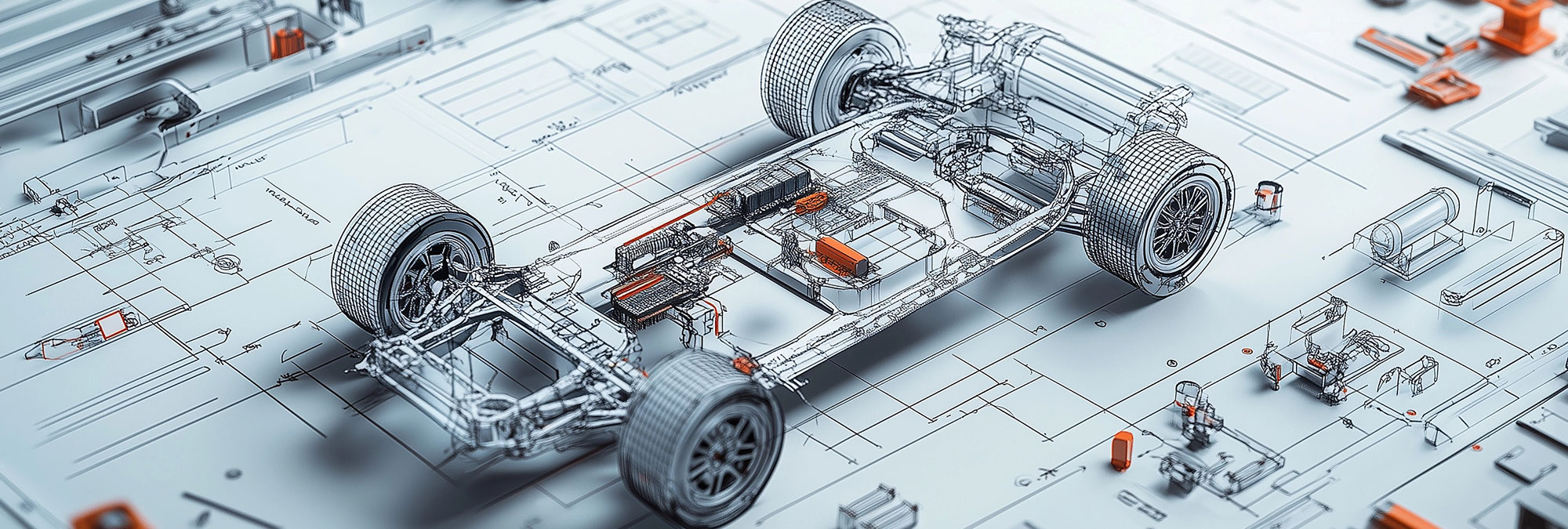

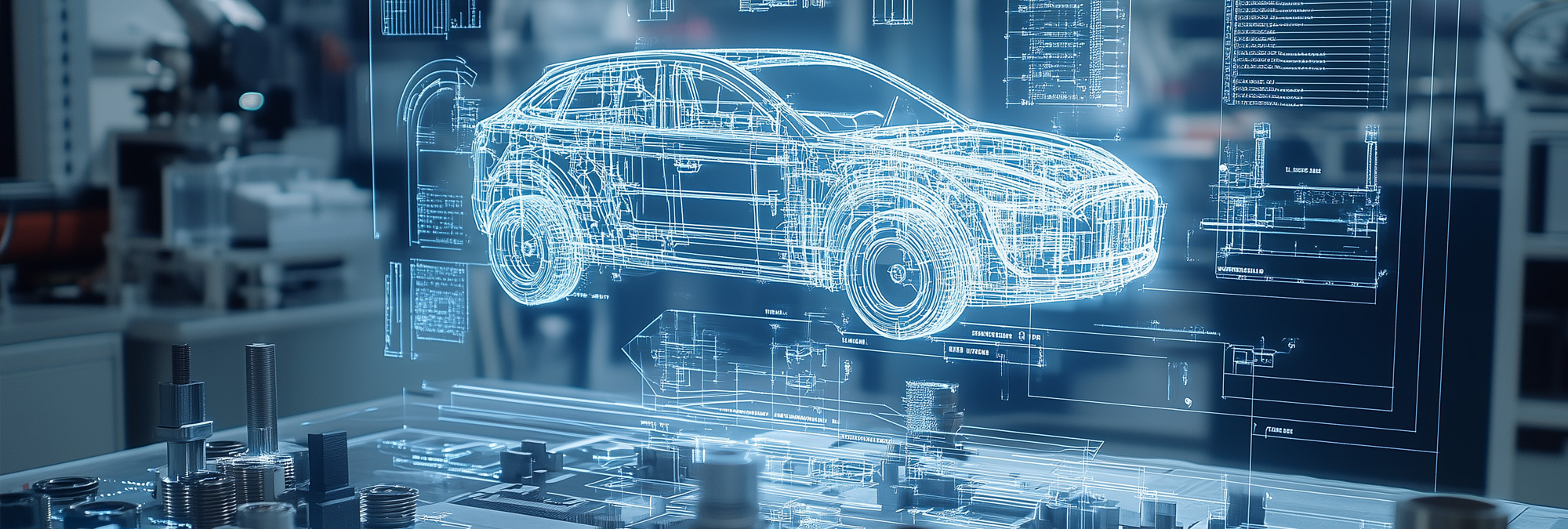

Reimagining automotive & e-mobility manufacturing

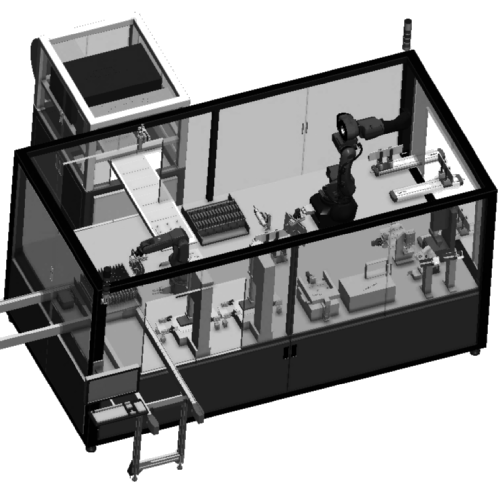

DWFritz brings decades of experience delivering high-speed, precision automation and inspection systems for the automotive and e-mobility sectors. As manufacturers integrate advanced robotics, AI, and electrification, we help them overcome the complexity of scaling safely and efficiently—without compromising quality.

Ready to begin?

Advanced solutions for automotive &

e-mobility

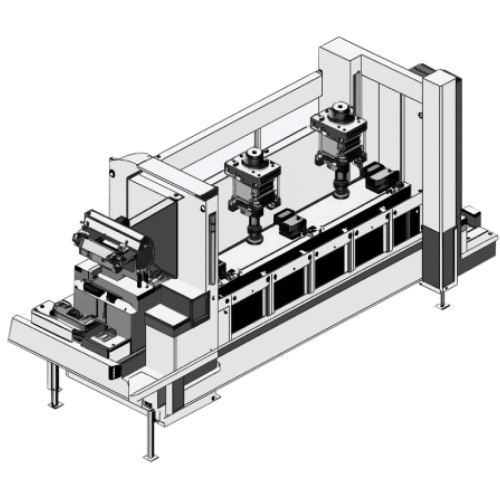

DWFritz combines deep expertise in assembly, inspection, and test automation with real-time software and process feedback to meet the high-precision, high-throughput demands of the automotive and e-mobility industries. Our advanced systems are built to handle complex manufacturing requirements with speed, accuracy, and scalability.

Want to see how we deliver results in action?

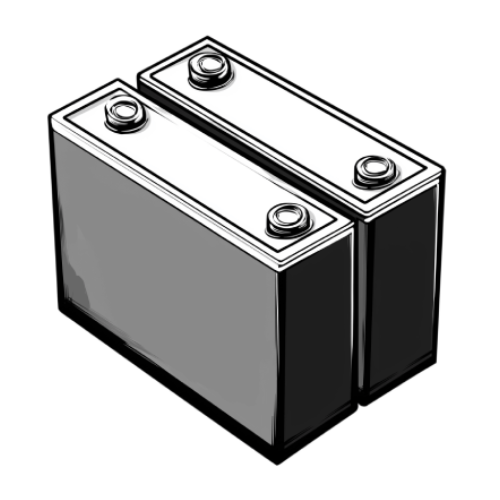

Explore our white paper on how we helped an electric vehicle manufacturer design a Battery Cell Test & Sort System—a pilot production tool engineered to pick, test, and sort lithium-ion cells with exceptional precision and reliability.

Battery Manufacturing Process

Drying and Calendaring

Notching and Slitting

Electrolyte Filling

Stacking

Pouch Formation / Sealing

Formation and Aging

Pack Assembly

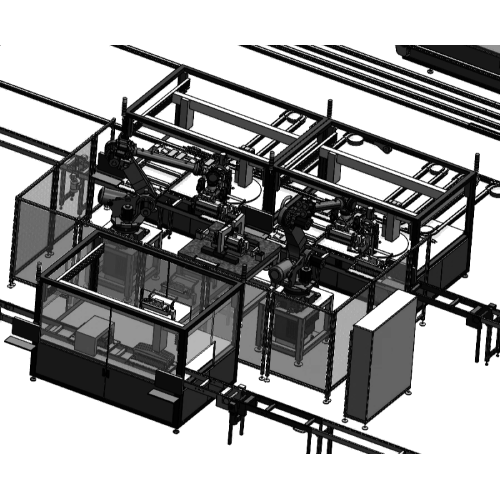

Module Assembly

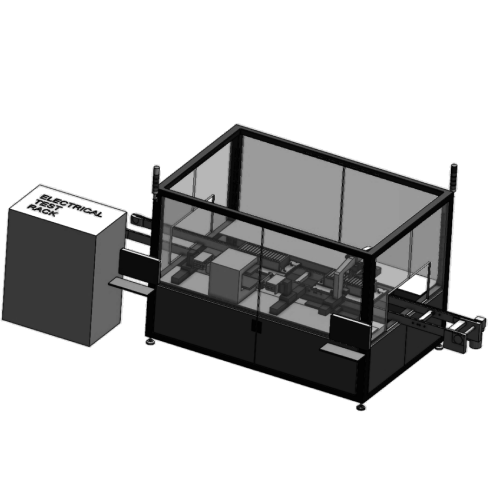

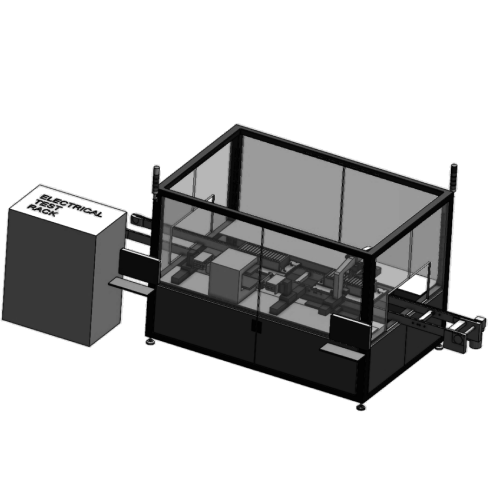

Electrical Test

Final Inspection

Electrode & tab inspection with digital twin

Singulated electrode & separator stacking

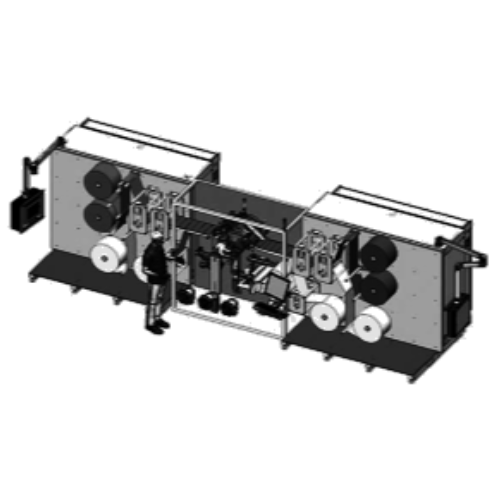

Material feed systems

Traceability

100% pure and post stacking inspection

Electrode & tab inspection with digital twin

- “Operator load or AGV delivers jumbo roll to unwinder

- Manual roll to roll splicing

- Laser or mechanical notching of electrodes

- Notched tab dimensions inspected

- Notch cleaned by ionizers and suction”, “Laser or mechanical roll slitting

- Roll material inspected for slitting dimensions

- Roll material cleaned by ionizers and suction”, “Dual output roll winding

Drying and Calendaring

Notching and Slitting

Stacking

Electrolyte Filling

Pouch Formation / Sealing

Formation and Aging

Module Assembly

Pack Assembly

Electrical Test

Final Inspection

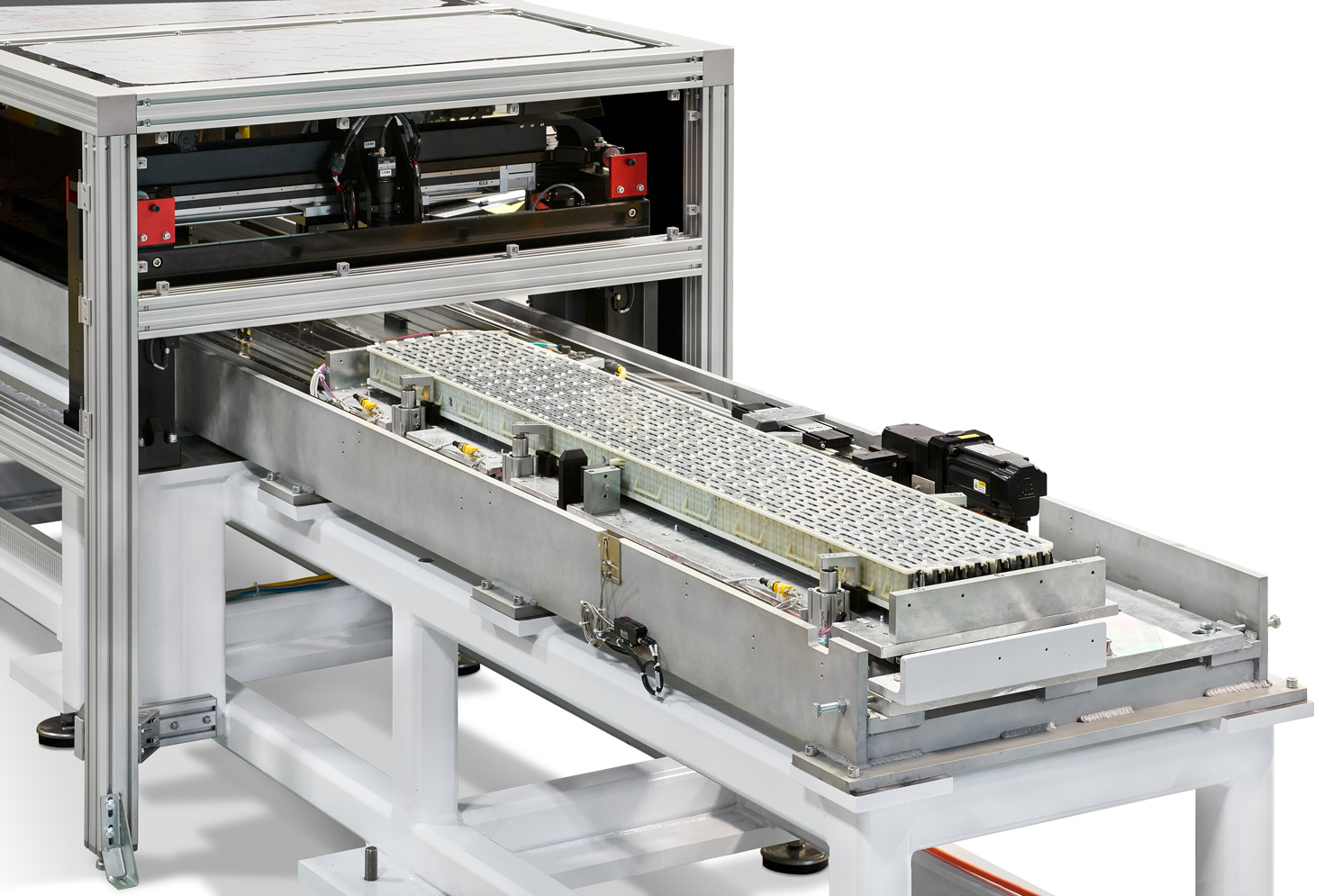

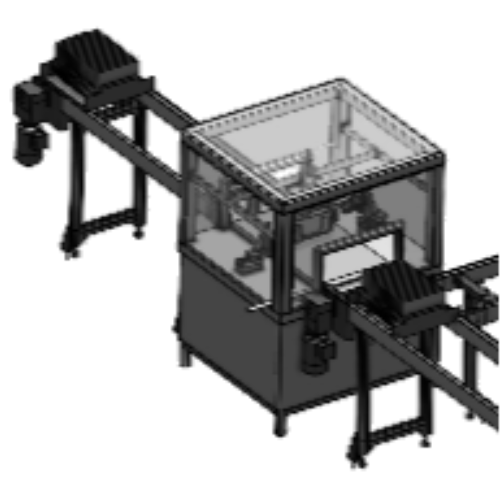

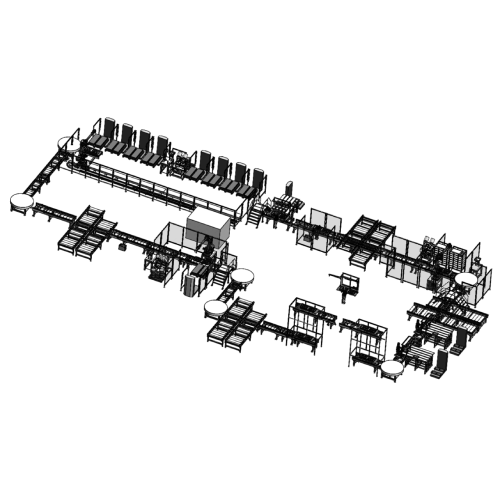

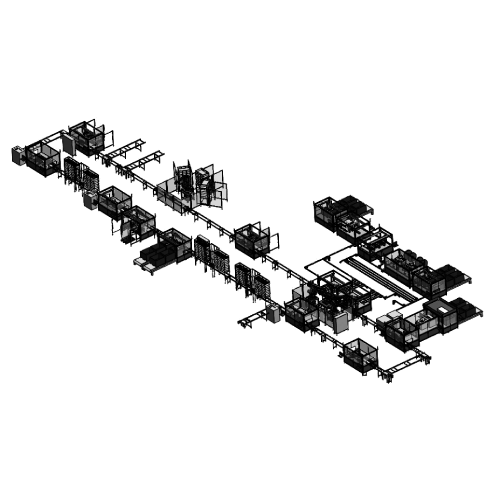

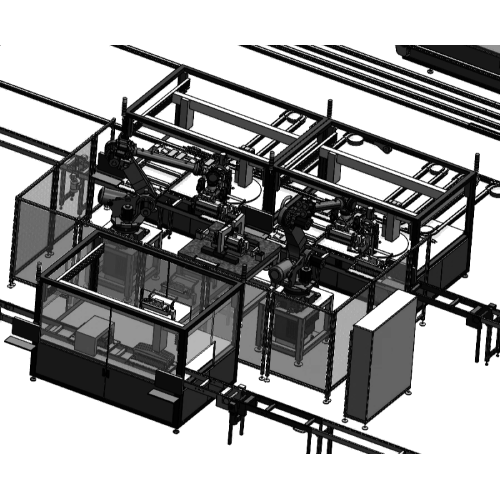

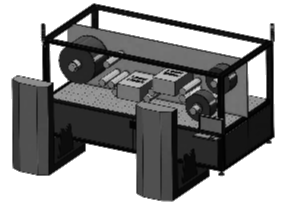

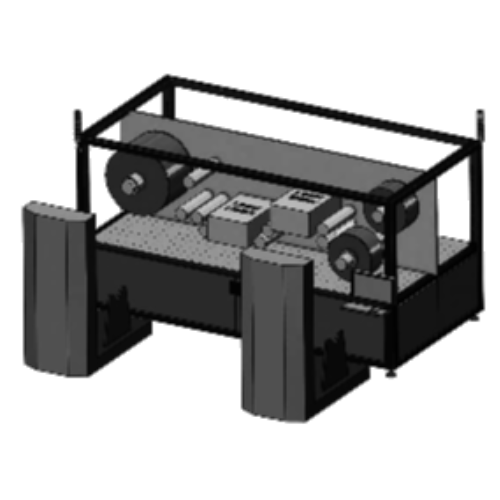

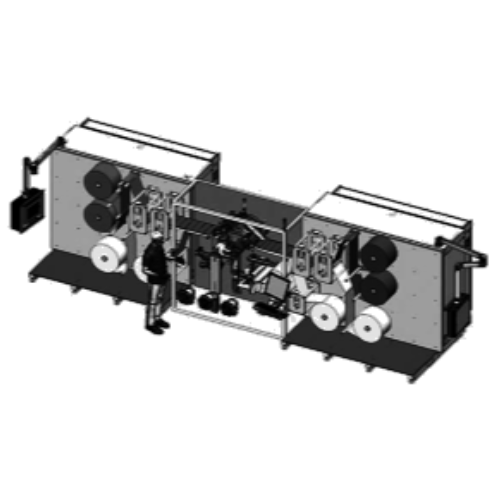

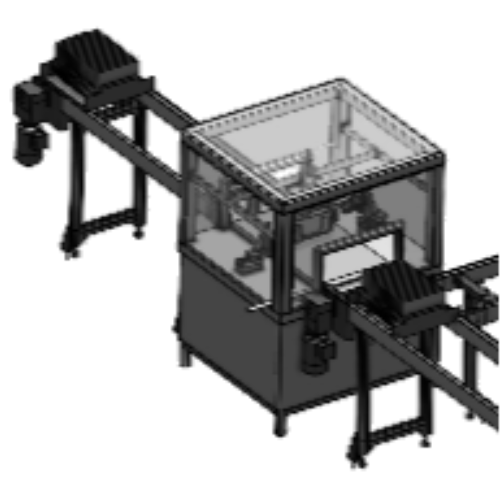

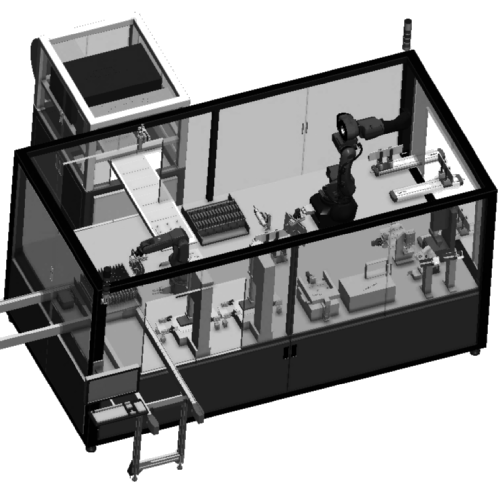

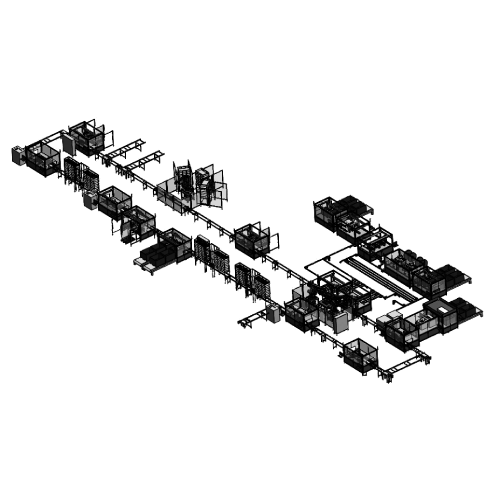

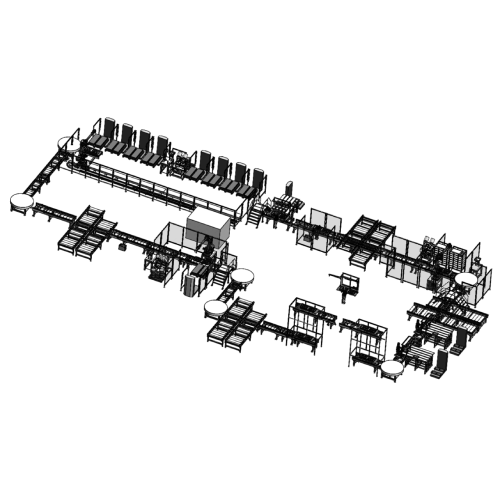

The images below are from a build of a complex line that was ~85m long for a manufacturer of electric buses used for public transportation.