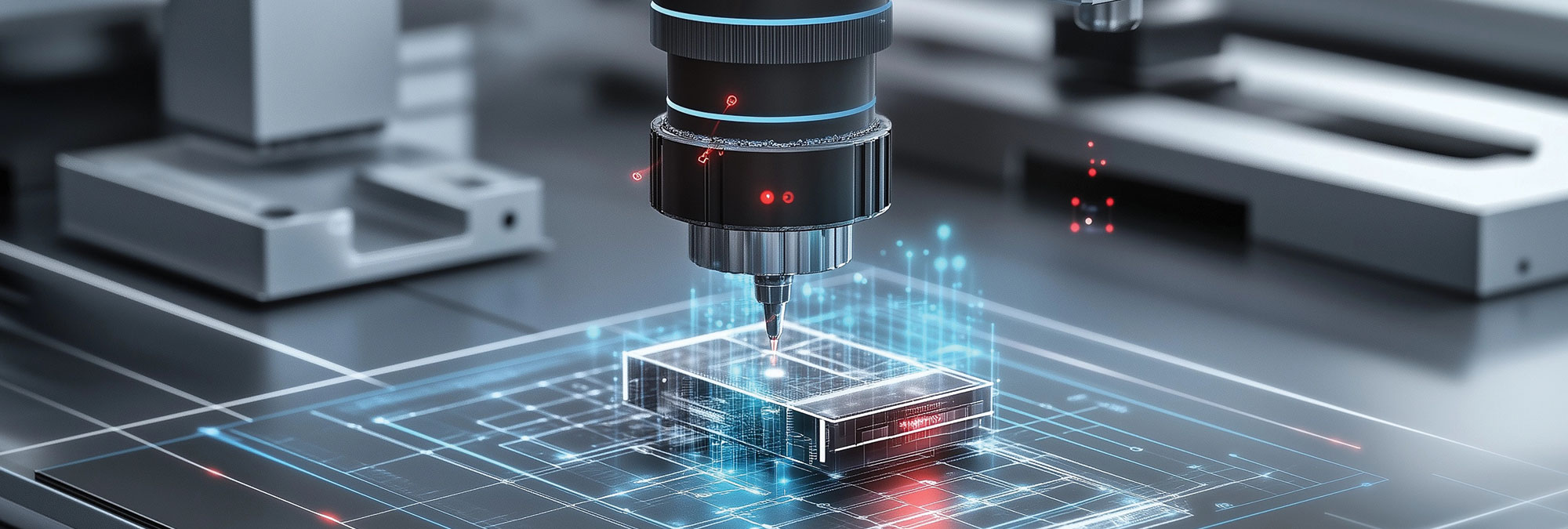

High-speed non-contact inline dimensional metrology

DWFritz is the industry leader in high-speed, noncontact metrology. Verify dimensions down to 1μm tolerances, with a high-speed measurement system that delivers full traceability and verification against spec, and eliminates defects in high-precision manufacturing.

Learn more about Metrology

Non-Contact Metrology Platform vs. Traditional CMM

Understanding the features of a non-contact metrology platform versus a traditional contact coordinate measuring machine (CMM) can help manufacturers choose the right equipment for inspection. By investing in the right…

Improving Yield Using High Speed Non-Contact Metrology

Speed, precision measurements and real-time data from non-contact metrology platforms make a difference in reducing scrap and improving yield for high volume consumer electronics manufacturers. In contract manufacturing, 100% inspection…

Benefits of Consolidating Metrology Operations into One System

Automated metrology platforms not only ensure high quality finished goods, these high speed solutions also lower total cost per part by consolidating multiple metrology operations into one system. High volume…

3 Key Benefits of an Automated Non-Contact Metrology System

In the precise world of advanced manufacturing, microns and milliseconds matter when inspecting class 3 medical devices, fitness trackers and smartphones to meet either government regulations or consumer standards. The…

Improving Long-Term Performance of Metrology Systems

In challenging manufacturing environments, 3 key factors influence the long-term performance of automated metrology systems installed in uncontrolled environments. Developing a metrology solution that consistently meets demanding production rates, yields…

Measuring Complex Part Geometries

Tightening dimensions are a trend both for components and for an increasing number of parts and devices. Incorrect part dimensional measurements can lead to failure and costly recalls. Small consumer…

Non-Contact Metrology Platform vs. Traditional CMM

Understanding the features of a non-contact metrology platform versus a traditional contact coordinate measuring machine (CMM) can help manufacturers choose the right equipment for inspection. By investing in the right…

Improving Yield Using High Speed Non-Contact Metrology

Speed, precision measurements and real-time data from non-contact metrology platforms make a difference in reducing scrap and improving yield for high volume consumer electronics manufacturers. In contract manufacturing, 100% inspection…

Benefits of Consolidating Metrology Operations into One System

Automated metrology platforms not only ensure high quality finished goods, these high speed solutions also lower total cost per part by consolidating multiple metrology operations into one system. High volume…

3 Key Benefits of an Automated Non-Contact Metrology System

In the precise world of advanced manufacturing, microns and milliseconds matter when inspecting class 3 medical devices, fitness trackers and smartphones to meet either government regulations or consumer standards. The…

Improving Long-Term Performance of Metrology Systems

In challenging manufacturing environments, 3 key factors influence the long-term performance of automated metrology systems installed in uncontrolled environments. Developing a metrology solution that consistently meets demanding production rates, yields…

Measuring Complex Part Geometries

Tightening dimensions are a trend both for components and for an increasing number of parts and devices. Incorrect part dimensional measurements can lead to failure and costly recalls. Small consumer…