In today’s rapidly evolving business landscape, understanding the core principles that drive product quality and profitability is paramount. Among these principles, the concepts of Value Added Value Engineering – (VA/VE) stand out as powerful tools that companies can leverage to gain a competitive edge. And VA/VE can be a game-changer. But how do they influence the way businesses design, produce, and sell their products?

In this article we will delve into this methodology, exploring its essence, impact, and how businesses, big and small, can integrate them for improved outcomes. Dive with us into the compelling intricacies of value and its pivotal role in modern business.

Defining Value

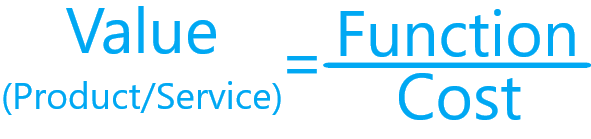

In value added and value engineering, the term ‘value’ often finds its foundation in the concept of use value—defined by a product’s attributes, its application, and purpose. Both value added and value engineering hinge on this understanding, shaping offerings to align with and exceed customer expectations. Enhancing value directly elevates customer satisfaction and increases loyalty.

Ready to begin?

VA/VE Unraveled: Understanding Value Added & Engineering

Broadly speaking, VA/VE is a manufacturing and engineering methodology that influences product design and its manufacturing. If done right, it can also improve upon process engineering. Originally, VA/VE emerged as a strategy during periods of national shortages where halting the manufacturing of crucial products wasn’t an option. However, after being integrated into manufacturing, engineers observed that VA/VE not only preserved product functionality but also resulted in cost savings. In certain instances, it even enhanced product performance. Its relevance was once again highlighted during the Covid-19 pandemic when supply chain disruptions exposed vulnerabilities across sectors, underscoring VA/VE’s effectiveness in addressing such challenges.

VA/VE aims to optimize a product or even a process by balancing cost and function. Through evaluating each functional attribute and its component cost-effectiveness, specialists collaborate to suggest alternative materials, designs, and techniques, ultimately aiming to reduce costs and enhance functionality.

Exploring the Core of Value Engineering

At the heart of VA/VE, value engineering is a method strategically employed prior to the manufacturing phase. Industry experts prioritize the preservation of a product’s inherent functions during this process, ensuring alignment with customer expectations. In the realm of value engineering, professionals contemplate alternative materials, design methodologies, manufacturing approaches, coding, DFM, DFA, component substitutions, and shipping logistics. Such depth in approach underscores the commitment to not only optimizing both cost and product functionality, but also manufacturability.

Building upon value engineering principles, its application can become a catalyst for product evolution. Teams merge diverse knowledge, ensuring the best decisions, from product design to material selection to manufacturing to shipment logistics. The outcome? Products that can be delivered to target markets at forecasted demand volume at the most optimal cost.

The impact of this methodology is most felt with the development of new products, where the products are designed with manufacturability in mind. This holistic approach is often used with existing products to optimize the cost value function to extract the best value.

Six Steps to Mastering Value Engineering

- Gather Information: Evaluating a product’s life cycle involves examining stages from design to manufacturing to sales and distribution.

- Think Creatively: Success in VE often involves embracing risks-be it through novel methods or reimagining established ones. It invites creative explorations: from material substitutions and design alterations to eliminating superfluous features or resequencing the manufacturing stages.

- Evaluate Ideas: Determine which concepts merit inclusion in the product, weighing each idea’s advantages and disadvantages.

- Develop and Analyze: After ranking, the top ideas undergo in-depth analysis. This involves creating model plans, detailing proposed changes and implications, revising financial estimates, timeline analysis, theory-of-constraints, resource analysis, updating design visualizations, and evaluating change viability.

- Present Discoveries: After finalizing plans and presentations, showcase the top ideas to senior leadership. Typically, multiple suggestions are tabled, accompanied by an updated timeline, financial forecasts, visualizations, and relevant references.

- Implementation and Monitoring: Once changes are implemented and production restarts, it’s crucial to monitor closely, ensuring the updated procedures function optimally.

VA/VE’s principles of cost efficiency and functional optimization are crucial across sectors like automotive, healthcare, manufacturing, and semiconductors. Its adaptability and emphasis on value make it a sought-after strategy among industry leaders in these domains.

Unpacking Value Added: The Enhancement of Product Worth

Value Added (VA) primarily emphasizes refining the existing products to elevate their market viability. It’s a strategic approach that can be seen most prominently in the assembly phase of manufacturing. This involves the integration of performance-enhancing components, leveraging the benefits of materials pricing arbitrage, and fine-tuning assembly processes.

The essence of VA is its application to products that are already in circulation. Through the VA process, engineers critically reassess the product, employing a wide array of strategies. They might focus on component alternatives, design considerations like ease of assembly, or methods to reduce costs and bolster function. Engineers may also consider incorporating AI based methods in the assembly or production process. The result? An enhanced product that not only meets, but often surpasses its original specifications, making it more commercially appealing.

Furthermore, VA presents opportunities across multiple facets of a product’s lifecycle, from design and engineering to its eventual recycling. Material selection, testing, manufacturing, shipping, installation, customer usage, service, and maintenance-all these areas can be optimized. Often, the initial designs of existing products are bound by stringent timelines. VA, however, offers an avenue to renegotiate costs, especially when ordering in larger volumes, harnessing the power of economies of scale.

DWFritz’s Distinctive Approach to VA/VE Excellence

At DWFritz, our dedication to delivering unmatched value is unwavering, ensuring our engineering and manufacturing processes consistently meet and exceed customer expectations. Our state-of-the-art facilities are uniquely designed with a pro-VA/VE focus. This architecture brings not only efficiency and innovation but also significant cost-savings to our clientele. By centralizing all services under one roof, we’ve optimized the process, ensuring streamlined management and tangible optimizations in production and inventory costs.

But it’s not just about infrastructure. We pride ourselves on our team of VA/VE specialists, experts singularly focused on maximizing ROI for our clients. Our years of industry experience cement our position as leaders in our fields, offering a level of reliability that’s second to none. Our engineers are staff cross-trained and well versed in all facets of advanced manufacturing and automation, bringing a heritage of 50 yrs to solve our clients advanced manufacturing challenges.

And yet, our journey doesn’t end there. At DWFritz, we’re continually driven by a passion for growth and innovation. We eagerly take on new projects, seeing every challenge as a fresh opportunity to refine our craft and deliver unparalleled solutions. When you choose DWFritz, you’re choosing a legacy of excellence and a future of innovation.

Concluding Thoughts

In our exploration of value within business and engineering realms, the significance of Value Added and Value Engineering is paramount. VA/VE serves as an essential method to amplify a product’s value, either by enhancing its function or by judiciously cutting its cost. As we navigate the complexities of modern day manufacturing, understanding and effectively employing VA/VE will be vital in consistently delivering products that meet and surpass user expectations, driving us towards unparalleled excellence.